Question: The separately uploaded figure shows a chemical processing system, where liquid reagents ( A ) and ( B ) react in

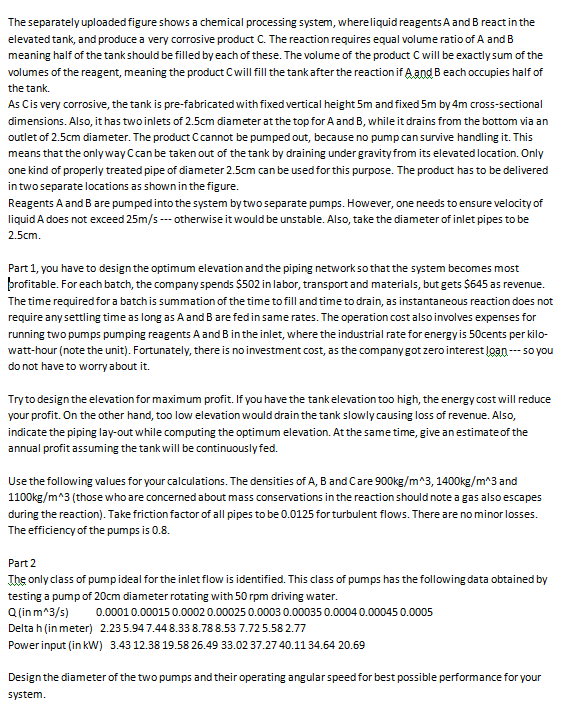

The separately uploaded figure shows a chemical processing system, where liquid reagents A and B react in the elevated tank, and produce a very corrosive product C The reaction requires equal volume ratio of A and B meaning half of the tank should be filled by each of these. The volume of the product C will be exactly sum of the volumes of the reagent, meaning the product C will fill the tank after the reaction if A and B each occupies half of the tank.

As Cis very corrosive, the tank is prefabricated with fixed vertical height m and fixed m by m crosssectional dimensions. Also, it has two inlets of cm diameter at the top for A and B while it drains from the bottom via an outlet of cm diameter. The product C cannot be pumped out, because no pump can survive handling it This means that the only way C can be taken out of the tank by draining under gravity from its elevated location. Only one kind of properly treated pipe of diameter cm can be used for this purpose. The product has to be delivered in two separate locations as shown in the figure.

Reagents A and B are pumped into the system by two separate pumps. However, one needs to ensure velocity of liquid A does not exceed mathrm~mmathrmscdots otherwise it would be unstable. Also, take the diameter of inlet pipes to be cm

Part you have to design the optimum elevation and the piping network so that the system becomes most profitable. For each batch, the company spends $ in labor, transport and materials, but gets $ as revenue. The time required for a batch is summation of the time to fill and time to drain, as instantaneous reaction does not require any settling time as long as A and B are fed in same rates. The operation cost also involves expenses for running two pumps pumping reagents A and B in the inlet, where the industrial rate for energy is cents per kilowatthour note the unit Fortunately, there is no investment cost, as the company got zero interest lgan so you do not have to worry about it

Try to design the elevation for maximum profit. If you have the tank elevation too high, the energy cost will reduce your profit. On the other hand, too low elevation would drain the tank slowly causing loss of revenue. Also, indicate the piping layout while computing the optimum elevation. At the same time, give an estimate of the annual profit assuming the tank will be continuously fed.

Use the following values for your calculations. The densities of A B and C are mathrm~kgmathrmmwedgemathrm~kgmathrmmwedge and mathrm~kgmathrmmwedgethose who are concerned about mass conservations in the reaction should note a gas also escapes during the reaction Take friction factor of all pipes to be for turbulent flows. There are no minor losses. The efficiency of the pumps is

Part

The only class of pump ideal for the inlet flow is identified. This class of pumps has the following data obtained by testing a pump of cm diameter rotating with rpm driving water.

Q in msquad

Delta h in meter

Power input in kW

Design the diameter of the two pumps and their operating angular speed for best possible performance for your system. The schematic of the processing plant

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock