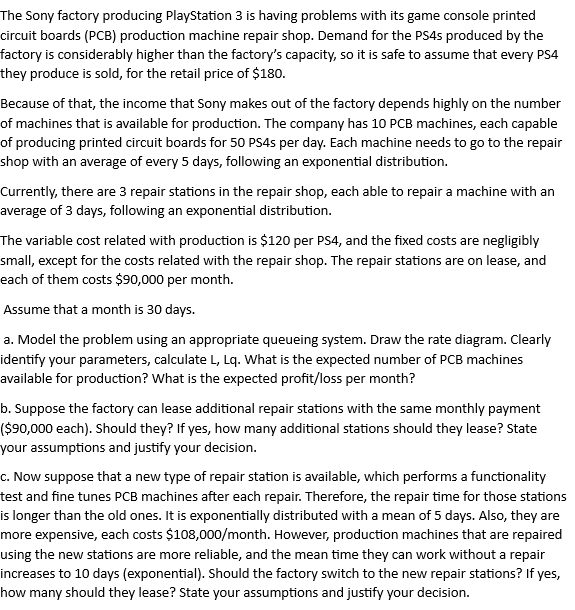

Question: The Sony factory producing PlayStation 3 is having problems with its game console printed circuit boards ( PCB ) production machine repair shop. Demand for

The Sony factory producing PlayStation is having problems with its game console printed

circuit boards PCB production machine repair shop. Demand for the PSs produced by the

factory is considerably higher than the factory's capacity, so it is safe to assume that every PS

they produce is sold, for the retail price of $

Because of that, the income that Sony makes out of the factory depends highly on the number

of machines that is available for production. The company has PCB machines, each capable

of producing printed circuit boards for PSs per day. Each machine needs to go to the repair

shop with an average of every days, following an exponential distribution.

Currently, there are repair stations in the repair shop, each able to repair a machine with an

average of days, following an exponential distribution.

The variable cost related with production is $ per PS and the fixed costs are negligibly

small, except for the costs related with the repair shop. The repair stations are on lease, and

each of them costs $ per month.

Assume that a month is days.

a Model the problem using an appropriate queueing system. Draw the rate diagram. Clearly

identify your parameters, calculate L Lq What is the expected number of PCB machines

available for production? What is the expected profitloss per month?

b Suppose the factory can lease additional repair stations with the same monthly payment

$ each Should they? If yes, how many additional stations should they lease? State

your assumptions and justify your decision.

c Now suppose that a new type of repair station is available, which performs a functionality

test and fine tunes PCB machines after each repair. Therefore, the repair time for those stations

is longer than the old ones. It is exponentially distributed with a mean of days. Also, they are

more expensive, each costs $ month. However, production machines that are repaired

using the new stations are more reliable, and the mean time they can work without a repair

increases to days exponential Should the factory switch to the new repair stations? If yes,

how many should they lease? State your assumptions and justify your decision.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock