Question: The welded duct assembly below has been designed by one of our customers for an aircraft application. The duct is part of a high pressure/low

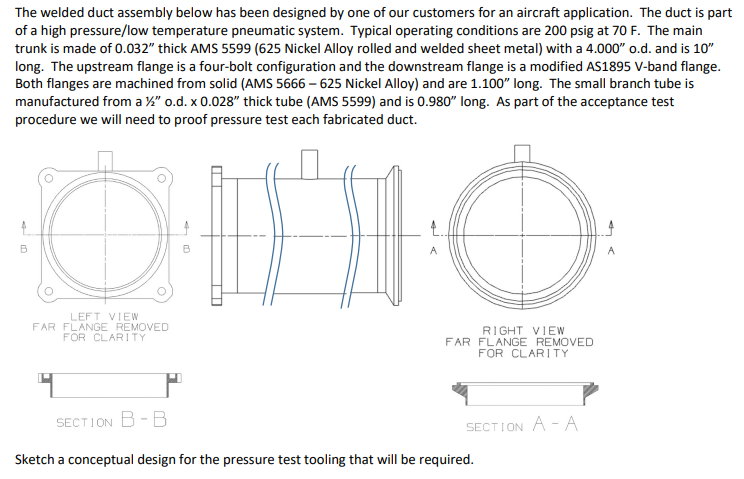

The welded duct assembly below has been designed by one of our customers for an aircraft application. The duct is part of a high pressure/low temperature pneumatic system. Typical operating conditions are 200 psig at 70F. The main trunk is made of 0.032" thick AMS 5599 (625 Nickel Alloy rolled and welded sheet metal) with a 4.000" o.d. and is 10" long. The upstream flange is a four-bolt configuration and the downstream flange is a modified AS1895 V-band flange. Both flanges are machined from solid (AMS 5666625 Nickel Alloy) and are 1.100 " long. The small branch tube is manufactured from a 1/2 " o.d. 0.028 thick tube (AMS 5599) and is 0.980 long. As part of the acceptance test procedure we will need to proof pressure test each fabricated duct. RIGHT VIEW FAR FLANGE REMOVED FOR CLARITY SECTION-SECTIONAA Sketch a conceptual design for the pressure test tooling that will be required

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts