Question: This is a Capstone Simulation related question. I am writing a strategic plan for the decisions made on the Total Quality Management of the simulation.

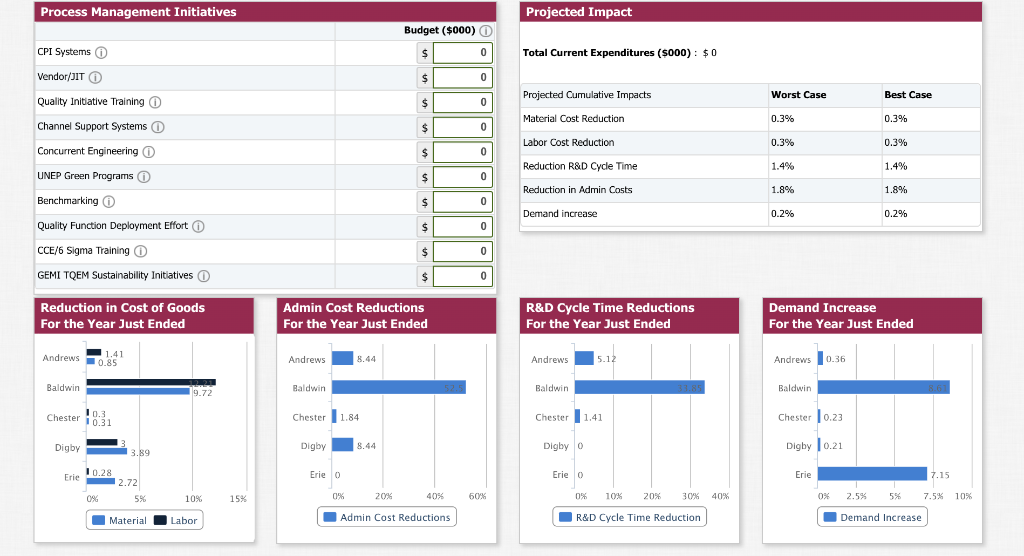

This is a Capstone Simulation related question. I am writing a strategic plan for the decisions made on the Total Quality Management of the simulation. What should I focus on? What sort of decisions should I be making every round to ensure profitability and sustainability? This is for a paper that I am writing. I know that there are multiple ways to approach this but one "best" way to approach it is all I need here to complete this section of my paper. Here is a screenshot of that section. Thank you for your feedback! section

section

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock