Question: This is project. And we need to improve the flow process by improving layout. Any method can be used to improve it. And here is

This is project. And we need to improve the flow process by improving layout. Any method can be used to improve it. And here is some information.

Can you suggest a way to improve the suggest the layout? Like rearrange their position and draw it again and explain the logic.

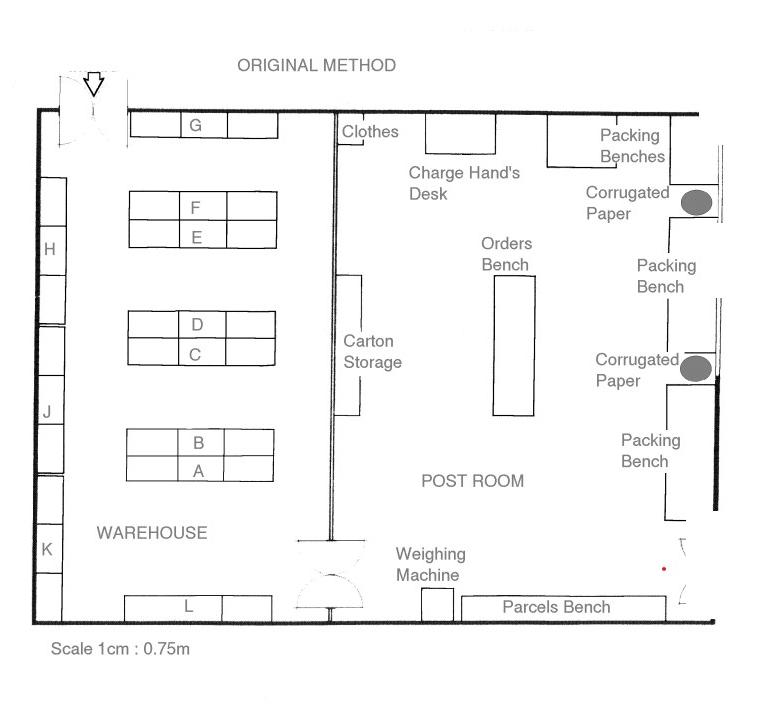

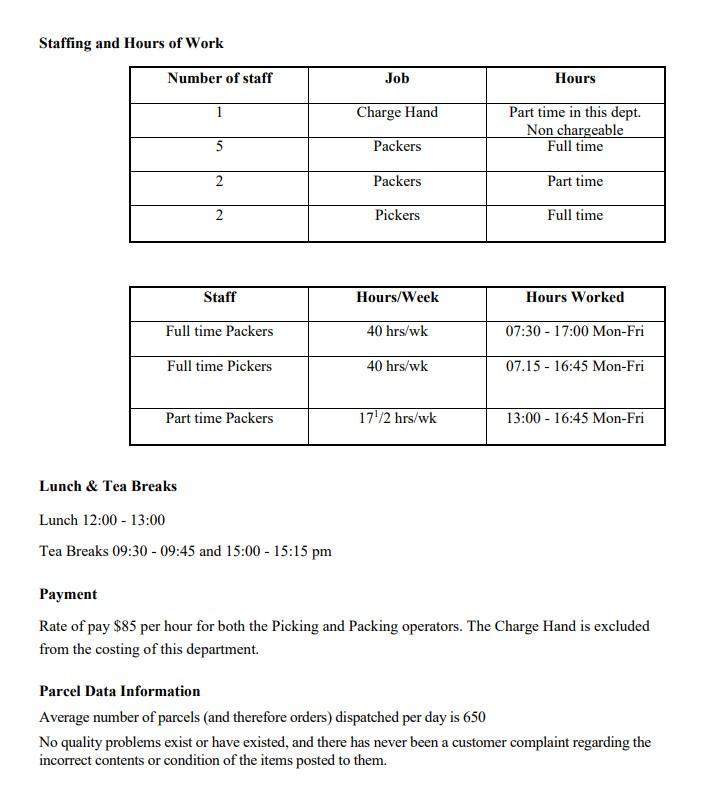

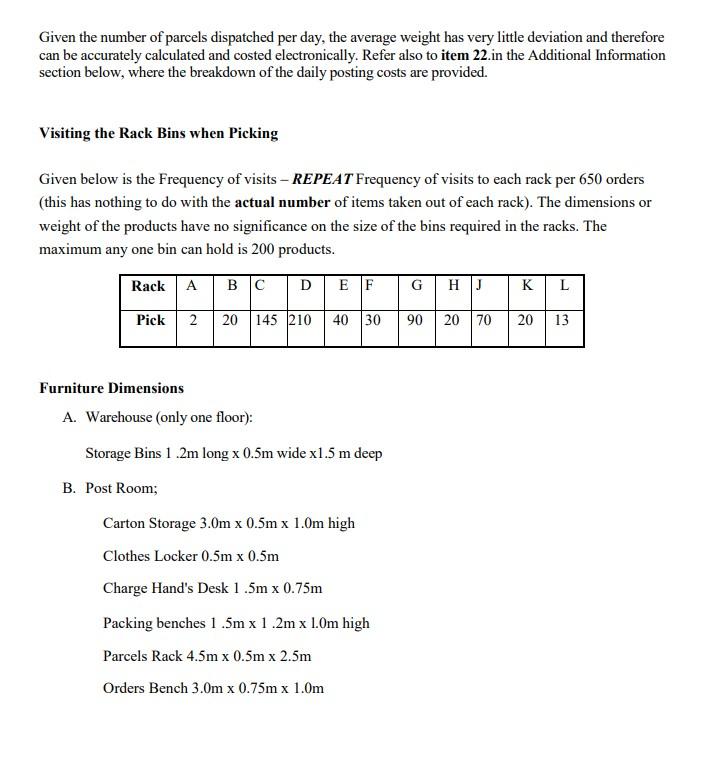

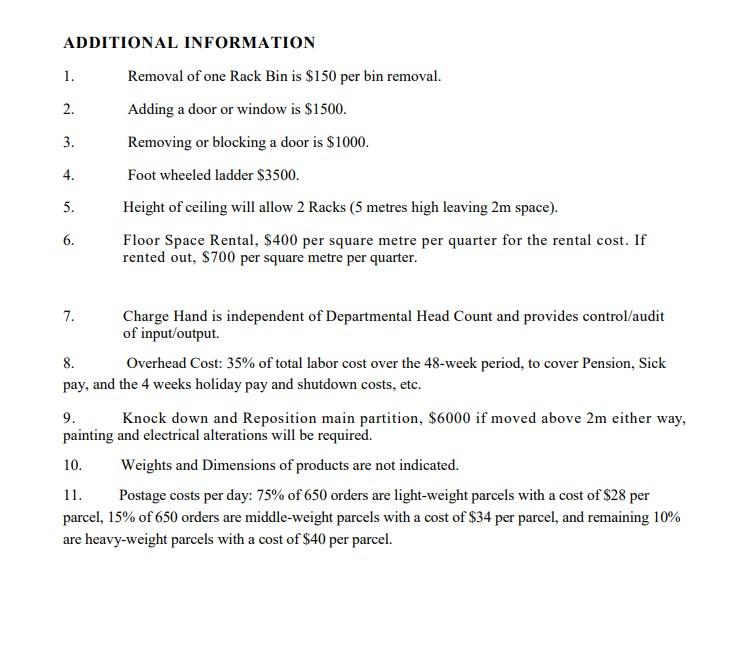

ORIGINAL METHOD G Clothes Packing Benches Charge Hand's Desk F Corrugated Paper E E H Orders Bench Packing Bench D Carton Storage Corrugated Paper J 00 Packing Bench POST ROOM WAREHOUSE K Weighing Machine Parcels Bench Scale 1cm : 0.75m Description of operations The Warehouse and Post Room of a small company HKplastics, specialises in the manufacture of Plastic goods. HKplastics picks items from its warehouse according to the orders and packs them up and deliver to end customers by hiring a third-party logistics company DHL. Items for each order are brought in from the adjacent warehouse by a Picker and are then checked against a picking note by a Packer. The picked items are then packed, weighed and put in a Parcel Bench for collection by the DHL. The barcoding and the electronic system of accounting for what is in stock, what has been picked and what has been sent, is considered to be accurate, modern and effective. The use of the hand held barcode reader by the Chargehand, Picker and Packer, for the purposes of this exercise is not in question, and no time or effort should be deployed in determining its efficiency or effectiveness. The following Picking and Packing methods, have been deployed for over ten years, sickness and absenteeism is rare, although there has been a noticeable drop in the physical pace and effort of the team who are all well into their 50's. Terms of Reference Area The Post Room and Warehouse are as shown on the layout diagram, separated by a timber and hardboard partitions. Depth A full investigation such as time and resources is needed (contained in the whole text), bearing in mind, the task objective as defined above. Work Load The workload and thus performance in this area, is based on 650 orders being dispatched per day, 5 days a week, for 48 weeks of the year. The average orders dispatched per day - 650 is an accurate total. Any costing and performance measu easures must be based on the 48 week year. PICKING OPERATORS - EXISTING METHOD The 2 picking operators work independently and their work consists of the following: 1. Walk from orders bench to Charge Hand's desk, pick up 6 orders at a time (3.7 m) - this literally means 6 sets of the Picking/ Advice note printouts. 2. Walk to trolley and place on trolley the paperwork. (0.5 m) 3. Push trolley to Rack 'A'! (11 m) and then follow the basic procedure as defined in item 4 next. 4. Against each order (P/A note ), check whether a product or a number of that product needs to be retrieved from the rack in question, moving onto each rack in tum ( alphabetical order), placing items on trolley where applicable, as follows.. i.e. Order Pick from 'A' To Racks 'B' & 'C' (4.5 m) Order Pick from 'B' & 'C' To Rack 'D' & 'E' (4.5 m) Order Pick from 'D' & 'E' and so on. The Distance from the mid point of 'F' & 'G' to Rack 'H' = 3.5m, from 'H' to 'J' = 2.5 m, from 'I' to 'K'= 2.5 m from 'K' to 'L' = 2.5 m. 5. Return to Post Room with trolley and products retrieved from the racks. 6. Deposit 6 trays worth of stock picked, plus the paper work on orders bench. End of cycle. The average time to pick 6 orders = 9 minutes (6 mins picking time and 3 mins walking time). PACKING OPERATORS - EXISTING METHOD The entire packing staff in this department work independently of the Picking Operators on the following work:- 1. Walk to orders bench. ( 4.5 m) 2. Check items for one parcel against one P/A note. 3. Return to packing bench with items on the tray and paper. (4.5 m) 4. Select appropriate sized carton from carton storage bench and make up. 5. Cut off length of corrugated paper place in Carton. 6. Place items, P/A note top copy into carton, detach label and bottom copy of P/A advice note. 7. Seal package with Tape. 8. Stick on label. 9. Walk to weighing machine, weigh parcel and record weight on bottom copy P/A note. (7m) 10. Place Parcel in Parcel Bench (0.5 m) 11. Walk to Chargehands desk and deposit bottom copy of P/A note. Average time to pack 5' /2 minutes. Packing time breakdown: Inspect 2 mins, Pack 2'/2 mins, Weigh & Dispatch Imin Information regarding the Picking/ Advice Note & Label These are sent by internal data transfer from the sales office to the Charge Hands' printer located on the Charge Hands' desk in the Post Room. The Picking/Advice note (top and bottom copy) contains a list of the items required for each order, and a label which has the customers' name and address. When finished with, the top copy of the Picking / Advice note is placed in the box containing the order items, with the bottom copy being returned to the Chargehands' desk for return to the Sales Accounts section. The Label is stuck onto the Carton in question. Staffing and Hours of Work Number of staff Job Hours 1 Charge Hand Part time in this dept. Non chargeable Full time 5 Packers 2 Packers Part time 2 Pickers Full time Staff Hours/Week Hours Worked Full time Packers 40 hrs/wk 07:30 - 17:00 Mon-Fri Full time Pickers 40 hrs/wk 07.15 - 16:45 Mon-Fri Part time Packers 17/2 hrs/wk 13:00 - 16:45 Mon-Fri Lunch & Tea Breaks Lunch 12:00 - 13:00 Tea Breaks 09:30 - 09:45 and 15:00 - 15:15 pm Payment Rate of pay $85 per hour for both the Picking and Packing operators. The Charge Hand is excluded from the costing of this department Parcel Data Information Average number of parcels (and therefore orders) dispatched per day is 650 No quality problems exist or have existed, and there has never been a customer complaint regarding the incorrect contents or condition of the items posted to them. Given the number of parcels dispatched per day, the average weight has very little deviation and therefore can be accurately calculated and costed electronically. Refer also to item 22. in the Additional Information section below, where the breakdown of the daily posting costs are provided. Visiting the Rack Bins when Picking Given below is the Frequency of visits - REPEAT Frequency of visits to each rack per 650 orders (this has nothing to do with the actual number of items taken out of each rack). The dimensions or weight of the products have no significance on the size of the bins required in the racks. The maximum any one bin can hold is 200 products. Rack A DEF G H K L Pick 2 20 145 210 40 30 90 20 70 20 13 Furniture Dimensions A. Warehouse (only one floor): Storage Bins 1.2m long x 0.5m wide x1.5 m deep B. Post Room; Carton Storage 3.0m x 0.5m x 1.0m high Clothes Locker 0.5m x 0.5m Charge Hand's Desk 1.5m x 0.75m Packing benches 1.5m x 1.2m x 1.0m high Parcels Rack 4.5m x 0.5m x 2.5m Orders Bench 3.0m x 0.75m x 1.0m ADDITIONAL INFORMATION 1. 2. 3. 4. Removal of one Rack Bin is $150 per bin removal. Adding a door or window is $1500. Removing or blocking a door is $1000. Foot wheeled ladder $3500. Height of ceiling will allow 2 Racks (5 metres high leaving 2m space). Floor Space Rental, $400 per square metre per quarter for the rental cost. If rented out, $700 per square metre per quarter. 5. 6. 7. Charge Hand is independent of Departmental Head Count and provides control/audit of input/output. 8. Overhead Cost: 35% of total labor cost over the 48-week period, to cover Pension, Sick pay, and the 4 weeks holiday pay and shutdown costs, etc. 9. Knock down and Reposition main partition, $6000 if moved above 2m either way, painting and electrical alterations will be required. Weights and Dimensions of products are not indicated. 11. Postage costs per day: 75% of 650 orders are light-weight parcels with a cost of $28 per parcel, 15% of 650 orders are middle-weight parcels with a cost of $34 per parcel, and remaining 10% are heavy-weight parcels with a cost of $40 per parcel. 10. ORIGINAL METHOD G Clothes Packing Benches Charge Hand's Desk F Corrugated Paper E E H Orders Bench Packing Bench D Carton Storage Corrugated Paper J 00 Packing Bench POST ROOM WAREHOUSE K Weighing Machine Parcels Bench Scale 1cm : 0.75m Description of operations The Warehouse and Post Room of a small company HKplastics, specialises in the manufacture of Plastic goods. HKplastics picks items from its warehouse according to the orders and packs them up and deliver to end customers by hiring a third-party logistics company DHL. Items for each order are brought in from the adjacent warehouse by a Picker and are then checked against a picking note by a Packer. The picked items are then packed, weighed and put in a Parcel Bench for collection by the DHL. The barcoding and the electronic system of accounting for what is in stock, what has been picked and what has been sent, is considered to be accurate, modern and effective. The use of the hand held barcode reader by the Chargehand, Picker and Packer, for the purposes of this exercise is not in question, and no time or effort should be deployed in determining its efficiency or effectiveness. The following Picking and Packing methods, have been deployed for over ten years, sickness and absenteeism is rare, although there has been a noticeable drop in the physical pace and effort of the team who are all well into their 50's. Terms of Reference Area The Post Room and Warehouse are as shown on the layout diagram, separated by a timber and hardboard partitions. Depth A full investigation such as time and resources is needed (contained in the whole text), bearing in mind, the task objective as defined above. Work Load The workload and thus performance in this area, is based on 650 orders being dispatched per day, 5 days a week, for 48 weeks of the year. The average orders dispatched per day - 650 is an accurate total. Any costing and performance measu easures must be based on the 48 week year. PICKING OPERATORS - EXISTING METHOD The 2 picking operators work independently and their work consists of the following: 1. Walk from orders bench to Charge Hand's desk, pick up 6 orders at a time (3.7 m) - this literally means 6 sets of the Picking/ Advice note printouts. 2. Walk to trolley and place on trolley the paperwork. (0.5 m) 3. Push trolley to Rack 'A'! (11 m) and then follow the basic procedure as defined in item 4 next. 4. Against each order (P/A note ), check whether a product or a number of that product needs to be retrieved from the rack in question, moving onto each rack in tum ( alphabetical order), placing items on trolley where applicable, as follows.. i.e. Order Pick from 'A' To Racks 'B' & 'C' (4.5 m) Order Pick from 'B' & 'C' To Rack 'D' & 'E' (4.5 m) Order Pick from 'D' & 'E' and so on. The Distance from the mid point of 'F' & 'G' to Rack 'H' = 3.5m, from 'H' to 'J' = 2.5 m, from 'I' to 'K'= 2.5 m from 'K' to 'L' = 2.5 m. 5. Return to Post Room with trolley and products retrieved from the racks. 6. Deposit 6 trays worth of stock picked, plus the paper work on orders bench. End of cycle. The average time to pick 6 orders = 9 minutes (6 mins picking time and 3 mins walking time). PACKING OPERATORS - EXISTING METHOD The entire packing staff in this department work independently of the Picking Operators on the following work:- 1. Walk to orders bench. ( 4.5 m) 2. Check items for one parcel against one P/A note. 3. Return to packing bench with items on the tray and paper. (4.5 m) 4. Select appropriate sized carton from carton storage bench and make up. 5. Cut off length of corrugated paper place in Carton. 6. Place items, P/A note top copy into carton, detach label and bottom copy of P/A advice note. 7. Seal package with Tape. 8. Stick on label. 9. Walk to weighing machine, weigh parcel and record weight on bottom copy P/A note. (7m) 10. Place Parcel in Parcel Bench (0.5 m) 11. Walk to Chargehands desk and deposit bottom copy of P/A note. Average time to pack 5' /2 minutes. Packing time breakdown: Inspect 2 mins, Pack 2'/2 mins, Weigh & Dispatch Imin Information regarding the Picking/ Advice Note & Label These are sent by internal data transfer from the sales office to the Charge Hands' printer located on the Charge Hands' desk in the Post Room. The Picking/Advice note (top and bottom copy) contains a list of the items required for each order, and a label which has the customers' name and address. When finished with, the top copy of the Picking / Advice note is placed in the box containing the order items, with the bottom copy being returned to the Chargehands' desk for return to the Sales Accounts section. The Label is stuck onto the Carton in question. Staffing and Hours of Work Number of staff Job Hours 1 Charge Hand Part time in this dept. Non chargeable Full time 5 Packers 2 Packers Part time 2 Pickers Full time Staff Hours/Week Hours Worked Full time Packers 40 hrs/wk 07:30 - 17:00 Mon-Fri Full time Pickers 40 hrs/wk 07.15 - 16:45 Mon-Fri Part time Packers 17/2 hrs/wk 13:00 - 16:45 Mon-Fri Lunch & Tea Breaks Lunch 12:00 - 13:00 Tea Breaks 09:30 - 09:45 and 15:00 - 15:15 pm Payment Rate of pay $85 per hour for both the Picking and Packing operators. The Charge Hand is excluded from the costing of this department Parcel Data Information Average number of parcels (and therefore orders) dispatched per day is 650 No quality problems exist or have existed, and there has never been a customer complaint regarding the incorrect contents or condition of the items posted to them. Given the number of parcels dispatched per day, the average weight has very little deviation and therefore can be accurately calculated and costed electronically. Refer also to item 22. in the Additional Information section below, where the breakdown of the daily posting costs are provided. Visiting the Rack Bins when Picking Given below is the Frequency of visits - REPEAT Frequency of visits to each rack per 650 orders (this has nothing to do with the actual number of items taken out of each rack). The dimensions or weight of the products have no significance on the size of the bins required in the racks. The maximum any one bin can hold is 200 products. Rack A DEF G H K L Pick 2 20 145 210 40 30 90 20 70 20 13 Furniture Dimensions A. Warehouse (only one floor): Storage Bins 1.2m long x 0.5m wide x1.5 m deep B. Post Room; Carton Storage 3.0m x 0.5m x 1.0m high Clothes Locker 0.5m x 0.5m Charge Hand's Desk 1.5m x 0.75m Packing benches 1.5m x 1.2m x 1.0m high Parcels Rack 4.5m x 0.5m x 2.5m Orders Bench 3.0m x 0.75m x 1.0m ADDITIONAL INFORMATION 1. 2. 3. 4. Removal of one Rack Bin is $150 per bin removal. Adding a door or window is $1500. Removing or blocking a door is $1000. Foot wheeled ladder $3500. Height of ceiling will allow 2 Racks (5 metres high leaving 2m space). Floor Space Rental, $400 per square metre per quarter for the rental cost. If rented out, $700 per square metre per quarter. 5. 6. 7. Charge Hand is independent of Departmental Head Count and provides control/audit of input/output. 8. Overhead Cost: 35% of total labor cost over the 48-week period, to cover Pension, Sick pay, and the 4 weeks holiday pay and shutdown costs, etc. 9. Knock down and Reposition main partition, $6000 if moved above 2m either way, painting and electrical alterations will be required. Weights and Dimensions of products are not indicated. 11. Postage costs per day: 75% of 650 orders are light-weight parcels with a cost of $28 per parcel, 15% of 650 orders are middle-weight parcels with a cost of $34 per parcel, and remaining 10% are heavy-weight parcels with a cost of $40 per parcel. 10Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts