Question: This is supply chain problem Best Technology (BT) is a leading manufacturer of adhesives used in a variety of industrial applications. BT produces two types

This is supply chain problem

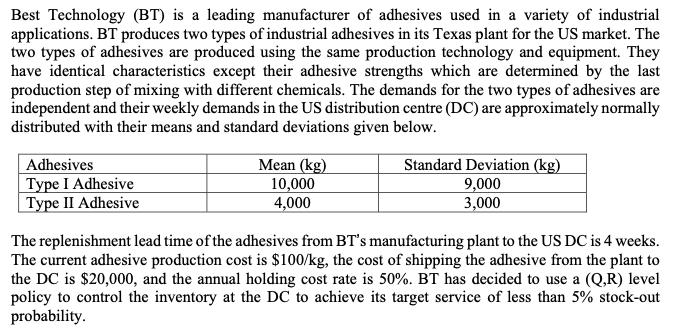

Best Technology (BT) is a leading manufacturer of adhesives used in a variety of industrial applications. BT produces two types of industrial adhesives in its Texas plant for the US market. The two types of adhesives are produced using the same production technology and equipment. They have identical characteristics except their adhesive strengths which are determined by the last production step of mixing with different chemicals. The demands for the two types of adhesives are independent and their weekly demands in the US distribution centre (DC) are approximately normally distributed with their means and standard deviations given below. Adhesives Mean (kg) Standard Deviation (kg) Type I Adhesive 10,000 9,000 Type II Adhesive 4,000 3,000 The replenishment lead time of the adhesives from BT's manufacturing plant to the US DC is 4 weeks. The current adhesive production cost is $100/kg, the cost of shipping the adhesive from the plant to the DC is $20,000, and the annual holding cost rate is 50%. BT has decided to use a (Q,R) level policy to control the inventory at the DC to achieve its target service of less than 5% stock-out probability. (b) Determine the amount of safety stock and the annual inventory cost of the two types of adhesives kept in the DC. (7 marks)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock