Question: THIS NEEDS TO BE CODED IN JAVA ONLY. SOLUTION CAN BE 75% OR ABOVE Introduction This coursework is set in a simulated car assembly factory.

THIS NEEDS TO BE CODED IN JAVA ONLY.

SOLUTION CAN BE 75% OR ABOVE

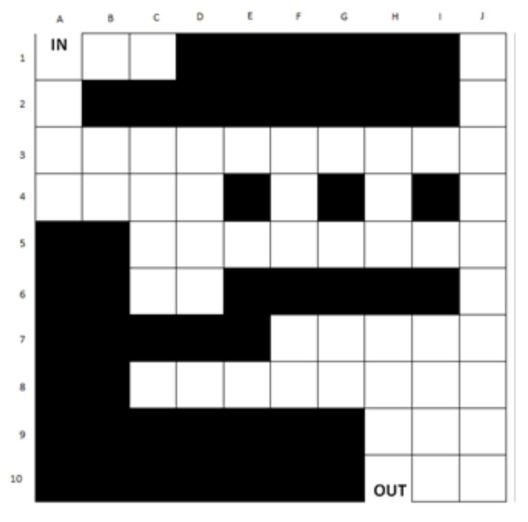

Introduction This coursework is set in a simulated car assembly factory. It involves completely designing and implementing basic algorithms that allow intelligent robots to operate a factory production line and so solve a number of common problems that arise when seeking computational solutions to real world problems. These include planning and scheduling problems together with more general problems of decision making in autonomous systems. Learning Outcome to be assessed -> Apply various computational techniques to solve many common problems. -> Understand how typical computational problems can be solved efficiently on a computer.  The main task is to develop a simulation, using AgentSheets, for the operation of a factory producing car body parts from sheet metal. The factory is almost completely autonomous and operated by robots. There are two parts to the problem: 1. Sheets of metal are delivered to the factory and placed randomly in a store room. The store room is equipped with floor sensors so that at any time the configuration of the store room is known. This is necessary because picker robots are required to traverse the store room and an accurate representation of the clear space, in which the robots can move, is required. The store room is divided into a 10x10 grid consisting of 100 sectors A1 to J10 and each sector may or may not contain a sheet of metal. An arrangement, at one particular point in time, is shown below with black squares (sectors) indicating the presence of a metal sheet and white squares indicating a clear sector on which the robot can move. Suppose you have a robot at the IN sector square (A1) requiring to traverse the stockroom and exit at the OUT sector square (H10). i. Develop a functional programming language representation of an efficient controller for the robots movement (Lisp or F#). Clearly state any assumptions you make. ii. Represent the options for the robots movement starting at A1 and develop the positional states that the robot can attain with each movement (assume the robot can only move left, right, up or down). Without fully expanding the solution space, show a path through a representation of the positional states of the robot that leads to the goal state (i.e H10). iii. Using the Manhattan Distance and depth of tree as heuristic and cost functions respectively annotate your state space representation with a number to represent the value of each particular state. iv. Discuss a range of algorithms that could be used to guide the path through the state space to provide the optimal solution. Comment in particular on Random, Breath/Depth First, Best First, A* and Simulated Annealing searches. 2. Once inside the factory the metal sheets are delivered to cutters who press the required shapes out of the sheet metal. The cut sheets are then taken to the welders who weld the panels together to form a skeleton car body. The car bodies are then taken to the riveters, who rivet the panels together. The car bodies are then taken to a storage area and from there loaded onto vans and taken to another facility for further processing. The cutters, welders and riveters are stationary and are maintained with power through a continuous fixed connection. Robots, which transport the sheets or car bodies use 1 unit of energy when travelling unladen and 2 units when transporting anything per simulation cycle. When their energy level becomes low robots must return to a robot room to recharge. They recharge at a rate of 5 units per simulation cycle. There are two quality levels of car body Prestige and Standard. Each order may be either Prestige or Standard. Both welders can produce standard car bodies but only welder 1 can produce the Prestige version. Welder 1 takes 7 simulation cycles to weld a car body together, whilst welder 2 takes 4 cycles. You should fully specify each agent in the scenario and design a solution for the factory, which you then go on to implement in an AgentSheets simulation. Your simulation should allow for the most efficient route through the factory, in time or quality, while minimizing the idleness of either welder. The factory only produces the two kinds of car body. The controller decides randomly when, what type and how many car bodies are produced and when a van comes to collect the manufactured product. When the number of metal sheets becomes low more should be delivered. Design the factory in Agentsheets, it is suggested that robots should move along specified paths, and implement algorithms in AgentSheets to show how the factory functions.

The main task is to develop a simulation, using AgentSheets, for the operation of a factory producing car body parts from sheet metal. The factory is almost completely autonomous and operated by robots. There are two parts to the problem: 1. Sheets of metal are delivered to the factory and placed randomly in a store room. The store room is equipped with floor sensors so that at any time the configuration of the store room is known. This is necessary because picker robots are required to traverse the store room and an accurate representation of the clear space, in which the robots can move, is required. The store room is divided into a 10x10 grid consisting of 100 sectors A1 to J10 and each sector may or may not contain a sheet of metal. An arrangement, at one particular point in time, is shown below with black squares (sectors) indicating the presence of a metal sheet and white squares indicating a clear sector on which the robot can move. Suppose you have a robot at the IN sector square (A1) requiring to traverse the stockroom and exit at the OUT sector square (H10). i. Develop a functional programming language representation of an efficient controller for the robots movement (Lisp or F#). Clearly state any assumptions you make. ii. Represent the options for the robots movement starting at A1 and develop the positional states that the robot can attain with each movement (assume the robot can only move left, right, up or down). Without fully expanding the solution space, show a path through a representation of the positional states of the robot that leads to the goal state (i.e H10). iii. Using the Manhattan Distance and depth of tree as heuristic and cost functions respectively annotate your state space representation with a number to represent the value of each particular state. iv. Discuss a range of algorithms that could be used to guide the path through the state space to provide the optimal solution. Comment in particular on Random, Breath/Depth First, Best First, A* and Simulated Annealing searches. 2. Once inside the factory the metal sheets are delivered to cutters who press the required shapes out of the sheet metal. The cut sheets are then taken to the welders who weld the panels together to form a skeleton car body. The car bodies are then taken to the riveters, who rivet the panels together. The car bodies are then taken to a storage area and from there loaded onto vans and taken to another facility for further processing. The cutters, welders and riveters are stationary and are maintained with power through a continuous fixed connection. Robots, which transport the sheets or car bodies use 1 unit of energy when travelling unladen and 2 units when transporting anything per simulation cycle. When their energy level becomes low robots must return to a robot room to recharge. They recharge at a rate of 5 units per simulation cycle. There are two quality levels of car body Prestige and Standard. Each order may be either Prestige or Standard. Both welders can produce standard car bodies but only welder 1 can produce the Prestige version. Welder 1 takes 7 simulation cycles to weld a car body together, whilst welder 2 takes 4 cycles. You should fully specify each agent in the scenario and design a solution for the factory, which you then go on to implement in an AgentSheets simulation. Your simulation should allow for the most efficient route through the factory, in time or quality, while minimizing the idleness of either welder. The factory only produces the two kinds of car body. The controller decides randomly when, what type and how many car bodies are produced and when a van comes to collect the manufactured product. When the number of metal sheets becomes low more should be delivered. Design the factory in Agentsheets, it is suggested that robots should move along specified paths, and implement algorithms in AgentSheets to show how the factory functions.

c D G H IN 10 2O OUT

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts