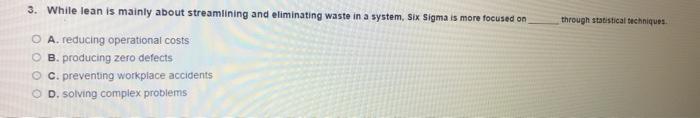

Question: through statistical techniques 3. While lean is mainly about streamlining and eliminating waste in a system, Six Sigma is more focused on O A. reducing

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock