Question: Ultra Instruments uses a manufacturing costing system with one direct-cost category (direct materials) and three indirect-cost categories: In response to competitive pressures at the end

Ultra Instruments uses a manufacturing costing system with one direct-cost category (direct materials) and three indirect-cost categories:

In response to competitive pressures at the end of

2016,

Ultra

Instruments used value-engineering techniques to reduce manufacturing costs. Actual information for

2016

and

2017

is as follows:

|

| 2016 | 2017 |

|---|---|---|

| Setup, production-order, and materials-handling costs per batch | $8,700 | $8,000 |

| Total manufacturing-operations cost per machine-hour | $56 | $52 |

| Cost per engineering change | $41,250 | $22,500 |

The management of

Ultra

Instruments wants to evaluate whether value engineering has succeeded in reducing the target manufacturing cost per unit of one of its products, HJ6, by

10%.

Actual results for

2016

and

2017

for HJ6 are:

|

| Actual Results for 2016 | Actual Results for 2017 |

|---|---|---|

| Units of HJ6 produced | 7,500 | 9,000 |

| Direct material cost per unit of HJ6 | $1,400 | $1,000 |

| Total number of batches required to produce HJ6 | 80 | 90 |

| Total machine-hours required to produce HJ6 | 50,250 | 43,200 |

| Number of engineering changes made | 10 | 8 |

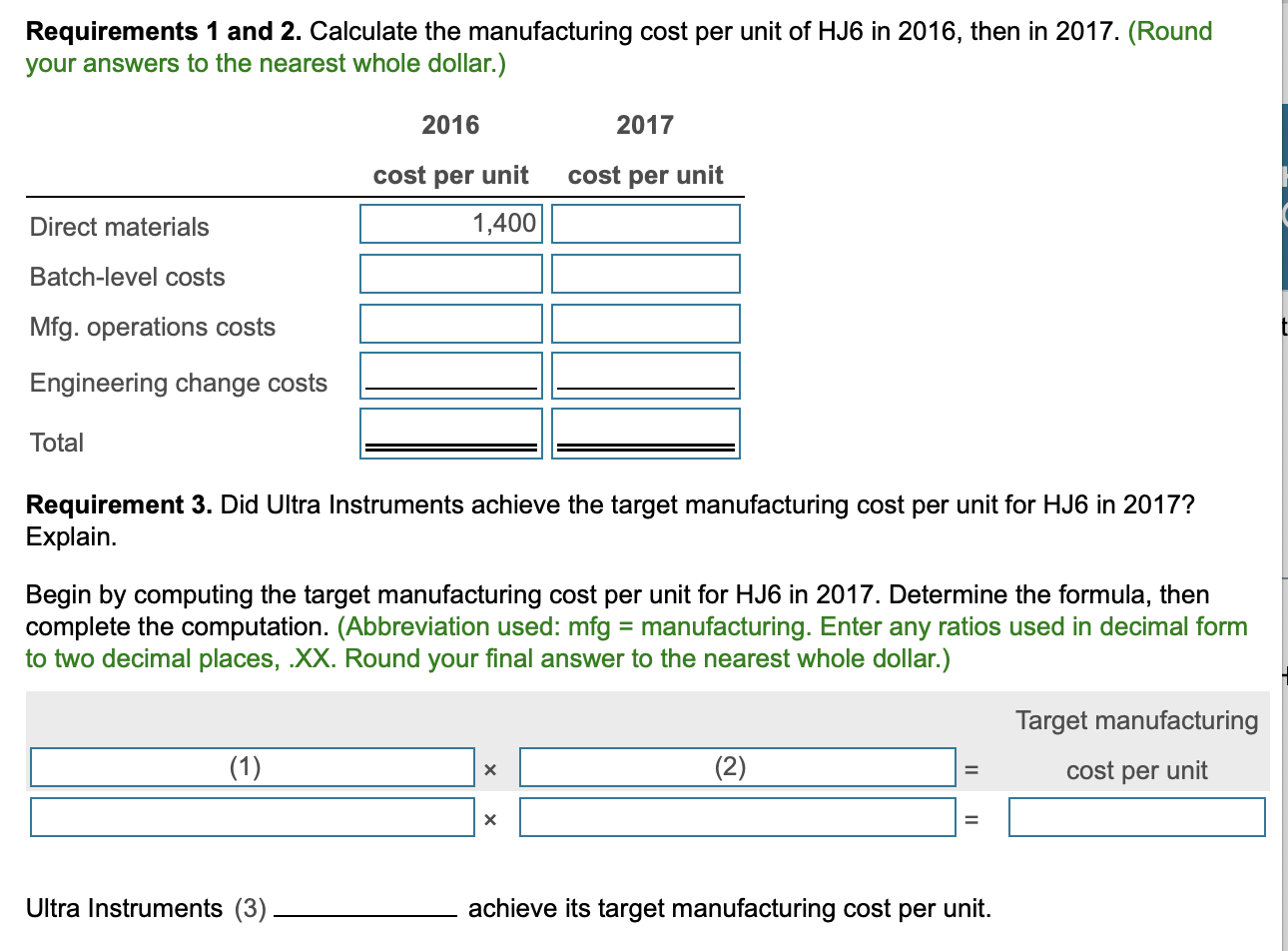

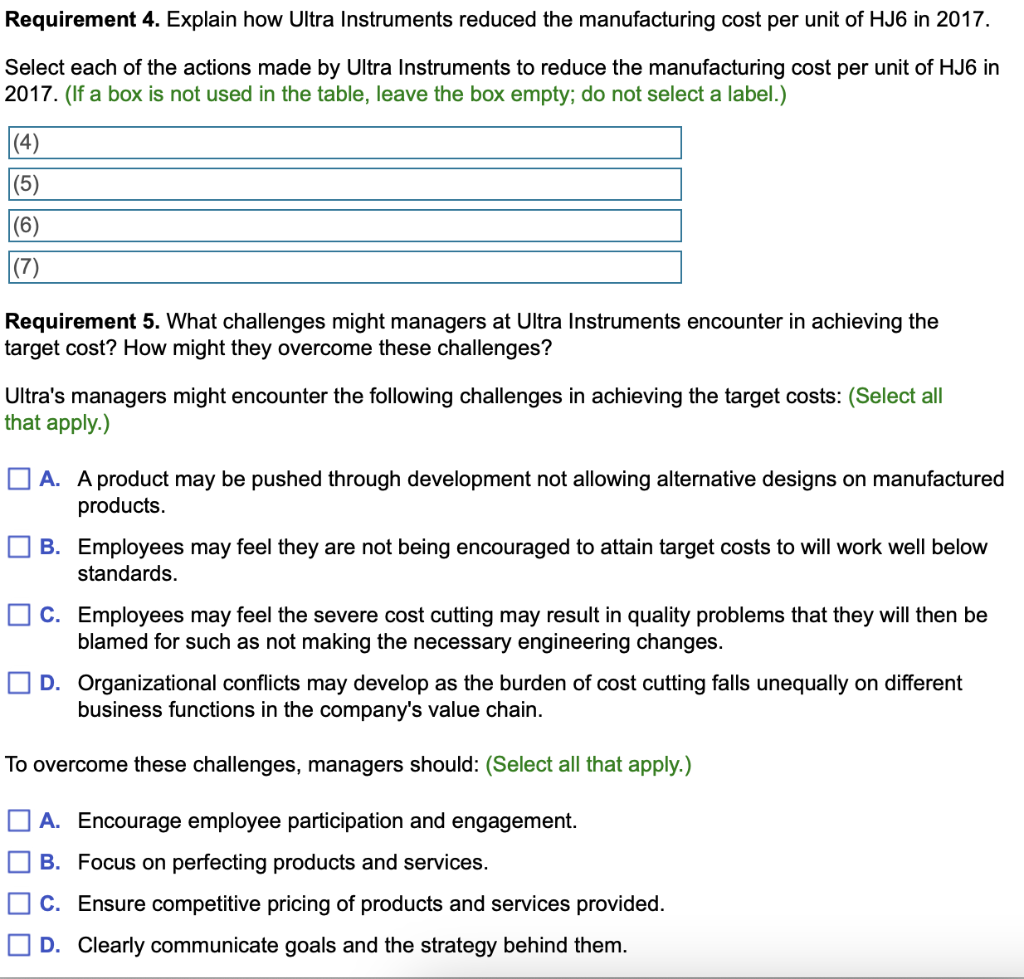

Requirements 1 and 2. Calculate the manufacturing cost per unit of HJ6 in 2016 , then in 2017. (Round your answers to the nearest whole dollar.) Requirement 3. Did Ultra Instruments achieve the target manufacturing cost per unit for HJ6 in 2017 ? Explain. Begin by computing the target manufacturing cost per unit for HJ6 in 2017. Determine the formula, then complete the computation. (Abbreviation used: mfg= manufacturing. Enter any ratios used in decimal form to two decimal places, .XX. Round your final answer to the nearest whole dollar.) Target manufacturing Requirement 4. Explain how Ultra Instruments reduced the manufacturing cost per unit of HJ6 in 2017. Select each of the actions made by Ultra Instruments to reduce the manufacturing cost per unit of HJ6 in 2017. (If a box is not used in the table, leave the box empty; do not select a label.) Requirement 5. What challenges might managers at Ultra Instruments encounter in achieving the target cost? How might they overcome these challenges? Ultra's managers might encounter the following challenges in achieving the target costs: (Select all that apply.) A. A product may be pushed through development not allowing alternative designs on manufactured products. B. Employees may feel they are not being encouraged to attain target costs to will work well below standards. C. Employees may feel the severe cost cutting may result in quality problems that they will then be blamed for such as not making the necessary engineering changes. D. Organizational conflicts may develop as the burden of cost cutting falls unequally on different business functions in the company's value chain. To overcome these challenges, managers should: (Select all that apply.) A. Encourage employee participation and engagement. B. Focus on perfecting products and services. C. Ensure competitive pricing of products and services provided. D. Clearly communicate goals and the strategy behind them. Requirements 1 and 2. Calculate the manufacturing cost per unit of HJ6 in 2016 , then in 2017. (Round your answers to the nearest whole dollar.) Requirement 3. Did Ultra Instruments achieve the target manufacturing cost per unit for HJ6 in 2017 ? Explain. Begin by computing the target manufacturing cost per unit for HJ6 in 2017. Determine the formula, then complete the computation. (Abbreviation used: mfg= manufacturing. Enter any ratios used in decimal form to two decimal places, .XX. Round your final answer to the nearest whole dollar.) Target manufacturing Requirement 4. Explain how Ultra Instruments reduced the manufacturing cost per unit of HJ6 in 2017. Select each of the actions made by Ultra Instruments to reduce the manufacturing cost per unit of HJ6 in 2017. (If a box is not used in the table, leave the box empty; do not select a label.) Requirement 5. What challenges might managers at Ultra Instruments encounter in achieving the target cost? How might they overcome these challenges? Ultra's managers might encounter the following challenges in achieving the target costs: (Select all that apply.) A. A product may be pushed through development not allowing alternative designs on manufactured products. B. Employees may feel they are not being encouraged to attain target costs to will work well below standards. C. Employees may feel the severe cost cutting may result in quality problems that they will then be blamed for such as not making the necessary engineering changes. D. Organizational conflicts may develop as the burden of cost cutting falls unequally on different business functions in the company's value chain. To overcome these challenges, managers should: (Select all that apply.) A. Encourage employee participation and engagement. B. Focus on perfecting products and services. C. Ensure competitive pricing of products and services provided. D. Clearly communicate goals and the strategy behind them

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts