Question: Urgent Solution! Please refer to the following case study and answer the following two questions. Q1: Identify the problem with current material procurement. Q2: What

Urgent Solution!

Please refer to the following case study and answer the following two questions.

Q1: Identify the problem with current material procurement.

Q2: What is the optimal solution, which needs accounting calculation to support.

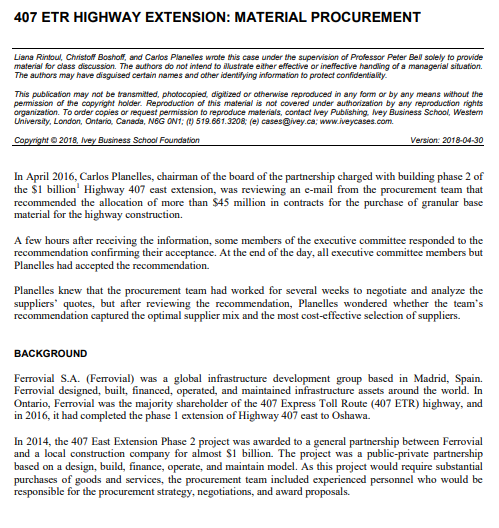

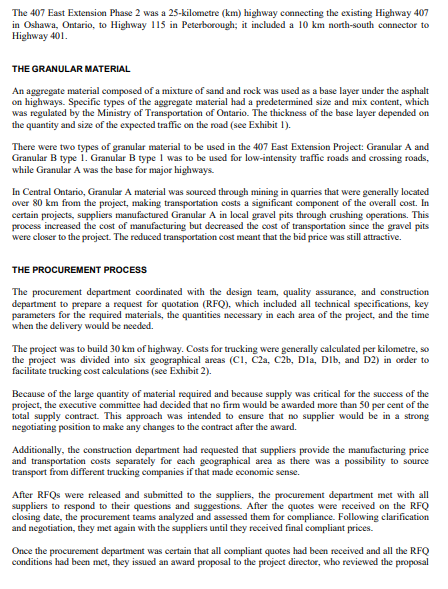

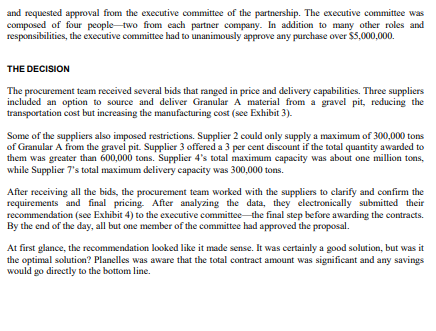

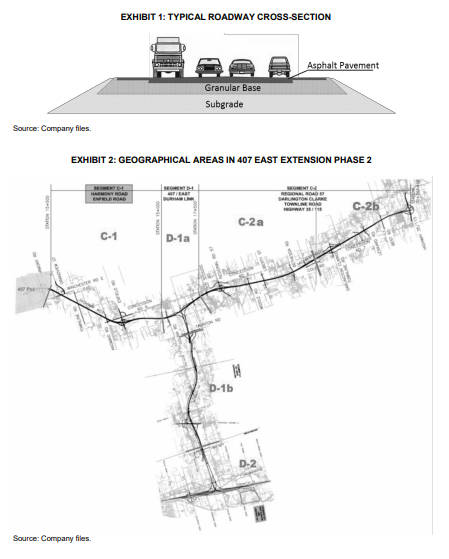

Word count: 300 words

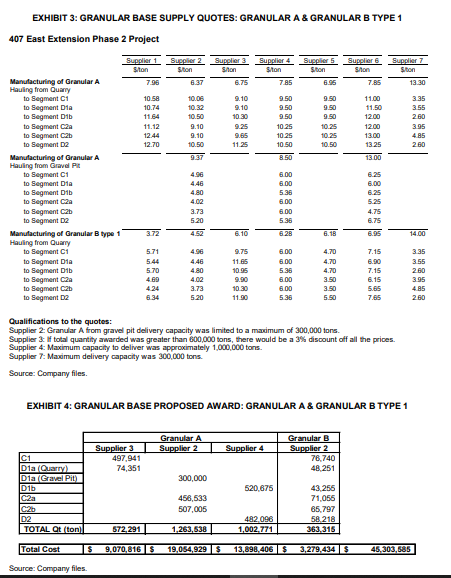

407 ETR HIGHWAY EXTENSION: MATERIAL PROCUREMENT Liana Rintoul, Christoff Boshoff, and Carlos Planelles wrote this case under the supervision of Professor Peter Bel solely to provide material for class discussion. The authors do not intend to illustrate either effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality This publication may not be transmitted, photocopied, digitized or otherwise reproduced in any form or by any means without the permission of the copyright holder. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials, contact Ivey Publishing. Ivey Business School, Western University, London, Ontario, Canada, N6G ON1: () 519.661.3208; (e) cases@ivey.ca; www.iveycases.com Copyright 2018, Ivey Business School Foundation Version: 2018-04-30 In April 2016, Carlos Planelles, chairman of the board of the partnership charged with building phase 2 of the $1 billion Highway 407 cast extension, was reviewing an e-mail from the procurement team that recommended the allocation of more than $45 million in contracts for the purchase of granular base material for the highway construction. A few hours after receiving the information, some members of the executive committee responded to the recommendation confirming their acceptance. At the end of the day, all executive committee members but Planelles had accepted the recommendation Planelles knew that the procurement team had worked for several weeks to negotiate and analyze the suppliers' quotes, but after reviewing the recommendation, Planelles wondered whether the team's recommendation captured the optimal supplier mix and the most cost-effective selection of suppliers. BACKGROUND Ferrovial S.A. (Ferrovial) was a global infrastructure development group based in Madrid, Spain. Ferrovial designed, built, financed, operated, and maintained infrastructure assets around the world. In Ontario, Ferrovial was the majority shareholder of the 407 Express Toll Route (407 ETR) highway, and in 2016, it had completed the phase 1 extension of Highway 407 cast to Oshawa. In 2014, the 407 East Extension Phase 2 project was awarded to a general partnership between Ferrovial and a local construction company for almost $1 billion. The project was a public-private partnership based on a design, build, finance, operate, and maintain model. As this project would require substantial purchases of goods and services, the procurement team included experienced personnel who would be responsible for the procurement strategy, negotiations, and award proposals. The 407 East Extension Phase 2 was a 25-kilometre (km) highway connecting the existing Highway 407 in Oshawa, Ontario, to Highway 115 in Peterborough; it included a 10 km north-south connector to Highway 401. THE GRANULAR MATERIAL An aggregate material composed of a mixture of sand and rock was used as a base layer under the asphalt on highways. Specific types of the aggregate material had a predetermined size and mix content, which was regulated by the Ministry of Transportation of Ontario. The thickness of the base layer depended on the quantity and size of the expected traffic on the road (see Exhibit 1). There were two types of granular material to be used in the 407 East Extension Project: Granular A and Granular B type 1. Granular B type I was to be used for low-intensity traffic roads and crossing roads, while Granular A was the base for major highways. In Central Ontario, Granular A material was sourced through mining in quarries that were generally located over 80 km from the project, making transportation costs a significant component of the overall cost. In certain projects, suppliers manufactured Granular A in local gravel pits through crushing operations. This process increased the cost of manufacturing but decreased the cost of transportation since the gravel pits were closer to the project. The reduced transportation cost meant that the bid price was still attractive. THE PROCUREMENT PROCESS The procurement department coordinated with the design team, quality assurance, and construction department to prepare a request for quotation (RFQ), which included all technical specifications, key parameters for the required materials, the quantities necessary in each area of the project, and the time when the delivery would be needed. The project was to build 30 km of highway. Costs for trucking were generally calculated per kilometre, so the project was divided into six geographical areas (CI, C2, C2b, Dla, Dib, and D2) in order to facilitate trucking cost calculations (see Exhibit 2). Because of the large quantity of material required and because supply was critical for the success of the project, the executive committee had decided that no firm would be awarded more than 50 per cent of the total supply contract. This approach was intended to ensure that no supplier would be in a strong negotiating position to make any changes to the contract after the award. Additionally, the construction department had requested that suppliers provide the manufacturing price and transportation costs separately for each geographical area as there was a possibility to source transport from different trucking companies if that made economic sense. After RFQs were released and submitted to the suppliers, the procurement department met with all suppliers to respond to their questions and suggestions. After the quotes were received on the RFQ closing date, the procurement teams analyzed and assessed them for compliance. Following clarification and negotiation, they met again with the suppliers until they received final compliant prices. Once the procurement department was certain that all compliant quotes had been received and all the RFQ conditions had been met, they issued an award proposal to the project director, who reviewed the proposal and requested approval from the executive committee of the partnership. The executive committee was composed of four peopletwo from each partner company. In addition to many other roles and responsibilities, the executive committee had to unanimously approve any purchase over $5,000,000. THE DECISION The procurement team received several bids that ranged in price and delivery capabilities. Three suppliers included an option to source and deliver Granular A material from a gravel pit, reducing the transportation cost but increasing the manufacturing cost (see Exhibit 3). Some of the suppliers also imposed restrictions. Supplier 2 could only supply a maximum of 300,000 tons of Granular A from the gravel pit. Supplier 3 offered a 3 per cent discount if the total quantity awarded to them was greater than 600,000 tons. Supplier 4's total maximum capacity was about one million tons, while Supplier 7's total maximum delivery capacity was 300.000 tons. After receiving all the bids, the procurement team worked with the suppliers to clarify and confirm the requirements and final pricing. After analyzing the data, they electronically submitted their recommendation (see Exhibit 4) to the executive committee the final step before awarding the contracts. By the end of the day, all but one member of the committee had approved the proposal. At first glance, the recommendation looked like it made sense. It was certainly a good solution, but was it the optimal solution? Planelles was aware that the total contract amount was significant and any savings would go directly to the bottom line. EXHIBIT 1: TYPICAL ROADWAY CROSS-SECTION Asphalt Pavement Granular Base Subgrade Source: Company files EXHIBIT 2: GEOGRAPHICAL AREAS IN 407 EAST EXTENSION PHASE 2 NGENTOT HOTEL AGORAL ROAD BARONE WAY C-26 C-2 a C-1 D-1a D-1b D.2 Source: Company files. 12.70 EXHIBIT 3: GRANULAR BASE SUPPLY QUOTES: GRANULAR A & GRANULAR B TYPE 1 407 East Extension Phase 2 Project Supplier 1 Supple2 Supplier 3 Supplier 4 Suspor 5 Supplier Supplier 7 Siton ston Son Siton Ston Sion ston Manufacturing of Granular A 7.96 6.37 6.75 7.85 6.96 7.85 13.30 Hauling from Ouary to Segmenti 10.50 10.00 9.10 9.50 9.50 11.00 3.35 to Segment Dla 10.74 10.32 9.10 9.50 9.50 11.50 3.55 to Segment D1b 11.64 10.30 9.50 9.50 12.00 2.60 to Segment 2 11.12 9.10 9.25 10.25 10.25 12.00 3.95 to Segment C2 12.44 9.10 9.65 10.25 10.25 13.00 4.85 to Segment D2 10.50 11.25 10.50 10.50 13.25 2.80 Manufacturing of Granular A 9.37 8.50 13.00 Hauling from Gravel PR to Segment 1 4.96 6.00 6.25 to Segment Dia 4.46 6.00 6.00 to Segment D1b 4.80 5.36 6.25 to Segmenta 4.02 6.00 5.25 to Segment c2b 3.73 6.00 4.75 to Segment D2 5.20 5.36 6.75 Manufacturing of Granular B type 1 4.52 6.10 6.28 6.18 6.95 14.00 Hauling from Quarry to Segment 1 5.71 4.96 9.75 6.00 4.70 7.15 3.35 to Segment to 5.44 4.46 11.65 6.00 4.70 6.90 to Segment Db 355 5.70 4.80 10.95 4.70 7.15 2.80 to Segment C2 4.69 4.02 9.90 6.00 3.50 6.15 3.95 to Segment C2b 424 3.73 10.30 6.00 3.50 5.65 4.85 to Segment 2 6.34 5.20 11.30 5.36 5.50 7.65 2.60 Says Qualifications to the quotes: Supplier 2: Granular A from gravel pit delivery capacity was limited to a maximum of 300,000 tons. Supplier 3 of total quantity awarded was greater than 600,000 tons, there would be a 3% discount off all the prices. Supplier 4: Maximum capacity to deliver was approximately 1,000,000 tons. Supplier 7: Maximum delivery capacity was 300,000 tons. Source: Company files. EXHIBIT 4: GRANULAR BASE PROPOSED AWARD: GRANULAR A & GRANULAR B TYPE 1 Granular A Supplier 2 Supplier 4 Supplier 3 497,941 74,351 Granular B Supplier 2 76.740 48.251 300,000 520,675 C1 Dia Quarry Dla Gravel Pit) D1b C2a C2 D2 TOTAL Qt (ton) 458,533 507,005 43,256 71,055 65.797 58.218 363.315 572 291 1.263,538 482.096 1.002.771 Total Cost $ 9.070,816S 19,054,9293 13,898,4065 3,279.434S 45.303,585 Source: Company files 407 ETR HIGHWAY EXTENSION: MATERIAL PROCUREMENT Liana Rintoul, Christoff Boshoff, and Carlos Planelles wrote this case under the supervision of Professor Peter Bel solely to provide material for class discussion. The authors do not intend to illustrate either effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality This publication may not be transmitted, photocopied, digitized or otherwise reproduced in any form or by any means without the permission of the copyright holder. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials, contact Ivey Publishing. Ivey Business School, Western University, London, Ontario, Canada, N6G ON1: () 519.661.3208; (e) cases@ivey.ca; www.iveycases.com Copyright 2018, Ivey Business School Foundation Version: 2018-04-30 In April 2016, Carlos Planelles, chairman of the board of the partnership charged with building phase 2 of the $1 billion Highway 407 cast extension, was reviewing an e-mail from the procurement team that recommended the allocation of more than $45 million in contracts for the purchase of granular base material for the highway construction. A few hours after receiving the information, some members of the executive committee responded to the recommendation confirming their acceptance. At the end of the day, all executive committee members but Planelles had accepted the recommendation Planelles knew that the procurement team had worked for several weeks to negotiate and analyze the suppliers' quotes, but after reviewing the recommendation, Planelles wondered whether the team's recommendation captured the optimal supplier mix and the most cost-effective selection of suppliers. BACKGROUND Ferrovial S.A. (Ferrovial) was a global infrastructure development group based in Madrid, Spain. Ferrovial designed, built, financed, operated, and maintained infrastructure assets around the world. In Ontario, Ferrovial was the majority shareholder of the 407 Express Toll Route (407 ETR) highway, and in 2016, it had completed the phase 1 extension of Highway 407 cast to Oshawa. In 2014, the 407 East Extension Phase 2 project was awarded to a general partnership between Ferrovial and a local construction company for almost $1 billion. The project was a public-private partnership based on a design, build, finance, operate, and maintain model. As this project would require substantial purchases of goods and services, the procurement team included experienced personnel who would be responsible for the procurement strategy, negotiations, and award proposals. The 407 East Extension Phase 2 was a 25-kilometre (km) highway connecting the existing Highway 407 in Oshawa, Ontario, to Highway 115 in Peterborough; it included a 10 km north-south connector to Highway 401. THE GRANULAR MATERIAL An aggregate material composed of a mixture of sand and rock was used as a base layer under the asphalt on highways. Specific types of the aggregate material had a predetermined size and mix content, which was regulated by the Ministry of Transportation of Ontario. The thickness of the base layer depended on the quantity and size of the expected traffic on the road (see Exhibit 1). There were two types of granular material to be used in the 407 East Extension Project: Granular A and Granular B type 1. Granular B type I was to be used for low-intensity traffic roads and crossing roads, while Granular A was the base for major highways. In Central Ontario, Granular A material was sourced through mining in quarries that were generally located over 80 km from the project, making transportation costs a significant component of the overall cost. In certain projects, suppliers manufactured Granular A in local gravel pits through crushing operations. This process increased the cost of manufacturing but decreased the cost of transportation since the gravel pits were closer to the project. The reduced transportation cost meant that the bid price was still attractive. THE PROCUREMENT PROCESS The procurement department coordinated with the design team, quality assurance, and construction department to prepare a request for quotation (RFQ), which included all technical specifications, key parameters for the required materials, the quantities necessary in each area of the project, and the time when the delivery would be needed. The project was to build 30 km of highway. Costs for trucking were generally calculated per kilometre, so the project was divided into six geographical areas (CI, C2, C2b, Dla, Dib, and D2) in order to facilitate trucking cost calculations (see Exhibit 2). Because of the large quantity of material required and because supply was critical for the success of the project, the executive committee had decided that no firm would be awarded more than 50 per cent of the total supply contract. This approach was intended to ensure that no supplier would be in a strong negotiating position to make any changes to the contract after the award. Additionally, the construction department had requested that suppliers provide the manufacturing price and transportation costs separately for each geographical area as there was a possibility to source transport from different trucking companies if that made economic sense. After RFQs were released and submitted to the suppliers, the procurement department met with all suppliers to respond to their questions and suggestions. After the quotes were received on the RFQ closing date, the procurement teams analyzed and assessed them for compliance. Following clarification and negotiation, they met again with the suppliers until they received final compliant prices. Once the procurement department was certain that all compliant quotes had been received and all the RFQ conditions had been met, they issued an award proposal to the project director, who reviewed the proposal and requested approval from the executive committee of the partnership. The executive committee was composed of four peopletwo from each partner company. In addition to many other roles and responsibilities, the executive committee had to unanimously approve any purchase over $5,000,000. THE DECISION The procurement team received several bids that ranged in price and delivery capabilities. Three suppliers included an option to source and deliver Granular A material from a gravel pit, reducing the transportation cost but increasing the manufacturing cost (see Exhibit 3). Some of the suppliers also imposed restrictions. Supplier 2 could only supply a maximum of 300,000 tons of Granular A from the gravel pit. Supplier 3 offered a 3 per cent discount if the total quantity awarded to them was greater than 600,000 tons. Supplier 4's total maximum capacity was about one million tons, while Supplier 7's total maximum delivery capacity was 300.000 tons. After receiving all the bids, the procurement team worked with the suppliers to clarify and confirm the requirements and final pricing. After analyzing the data, they electronically submitted their recommendation (see Exhibit 4) to the executive committee the final step before awarding the contracts. By the end of the day, all but one member of the committee had approved the proposal. At first glance, the recommendation looked like it made sense. It was certainly a good solution, but was it the optimal solution? Planelles was aware that the total contract amount was significant and any savings would go directly to the bottom line. EXHIBIT 1: TYPICAL ROADWAY CROSS-SECTION Asphalt Pavement Granular Base Subgrade Source: Company files EXHIBIT 2: GEOGRAPHICAL AREAS IN 407 EAST EXTENSION PHASE 2 NGENTOT HOTEL AGORAL ROAD BARONE WAY C-26 C-2 a C-1 D-1a D-1b D.2 Source: Company files. 12.70 EXHIBIT 3: GRANULAR BASE SUPPLY QUOTES: GRANULAR A & GRANULAR B TYPE 1 407 East Extension Phase 2 Project Supplier 1 Supple2 Supplier 3 Supplier 4 Suspor 5 Supplier Supplier 7 Siton ston Son Siton Ston Sion ston Manufacturing of Granular A 7.96 6.37 6.75 7.85 6.96 7.85 13.30 Hauling from Ouary to Segmenti 10.50 10.00 9.10 9.50 9.50 11.00 3.35 to Segment Dla 10.74 10.32 9.10 9.50 9.50 11.50 3.55 to Segment D1b 11.64 10.30 9.50 9.50 12.00 2.60 to Segment 2 11.12 9.10 9.25 10.25 10.25 12.00 3.95 to Segment C2 12.44 9.10 9.65 10.25 10.25 13.00 4.85 to Segment D2 10.50 11.25 10.50 10.50 13.25 2.80 Manufacturing of Granular A 9.37 8.50 13.00 Hauling from Gravel PR to Segment 1 4.96 6.00 6.25 to Segment Dia 4.46 6.00 6.00 to Segment D1b 4.80 5.36 6.25 to Segmenta 4.02 6.00 5.25 to Segment c2b 3.73 6.00 4.75 to Segment D2 5.20 5.36 6.75 Manufacturing of Granular B type 1 4.52 6.10 6.28 6.18 6.95 14.00 Hauling from Quarry to Segment 1 5.71 4.96 9.75 6.00 4.70 7.15 3.35 to Segment to 5.44 4.46 11.65 6.00 4.70 6.90 to Segment Db 355 5.70 4.80 10.95 4.70 7.15 2.80 to Segment C2 4.69 4.02 9.90 6.00 3.50 6.15 3.95 to Segment C2b 424 3.73 10.30 6.00 3.50 5.65 4.85 to Segment 2 6.34 5.20 11.30 5.36 5.50 7.65 2.60 Says Qualifications to the quotes: Supplier 2: Granular A from gravel pit delivery capacity was limited to a maximum of 300,000 tons. Supplier 3 of total quantity awarded was greater than 600,000 tons, there would be a 3% discount off all the prices. Supplier 4: Maximum capacity to deliver was approximately 1,000,000 tons. Supplier 7: Maximum delivery capacity was 300,000 tons. Source: Company files. EXHIBIT 4: GRANULAR BASE PROPOSED AWARD: GRANULAR A & GRANULAR B TYPE 1 Granular A Supplier 2 Supplier 4 Supplier 3 497,941 74,351 Granular B Supplier 2 76.740 48.251 300,000 520,675 C1 Dia Quarry Dla Gravel Pit) D1b C2a C2 D2 TOTAL Qt (ton) 458,533 507,005 43,256 71,055 65.797 58.218 363.315 572 291 1.263,538 482.096 1.002.771 Total Cost $ 9.070,816S 19,054,9293 13,898,4065 3,279.434S 45.303,585 Source: Company files

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts