Question: Using a process that you are familiar with, identify the bottleneck of the process, identify the drum, buffer, rope of the process. Using the same

- Using a process that you are familiar with, identify the bottleneck of the process, identify the drum, buffer, rope of the process. Using the same process, identify conditions that would lead to the bottleneck changing or shifting away from the existing one.

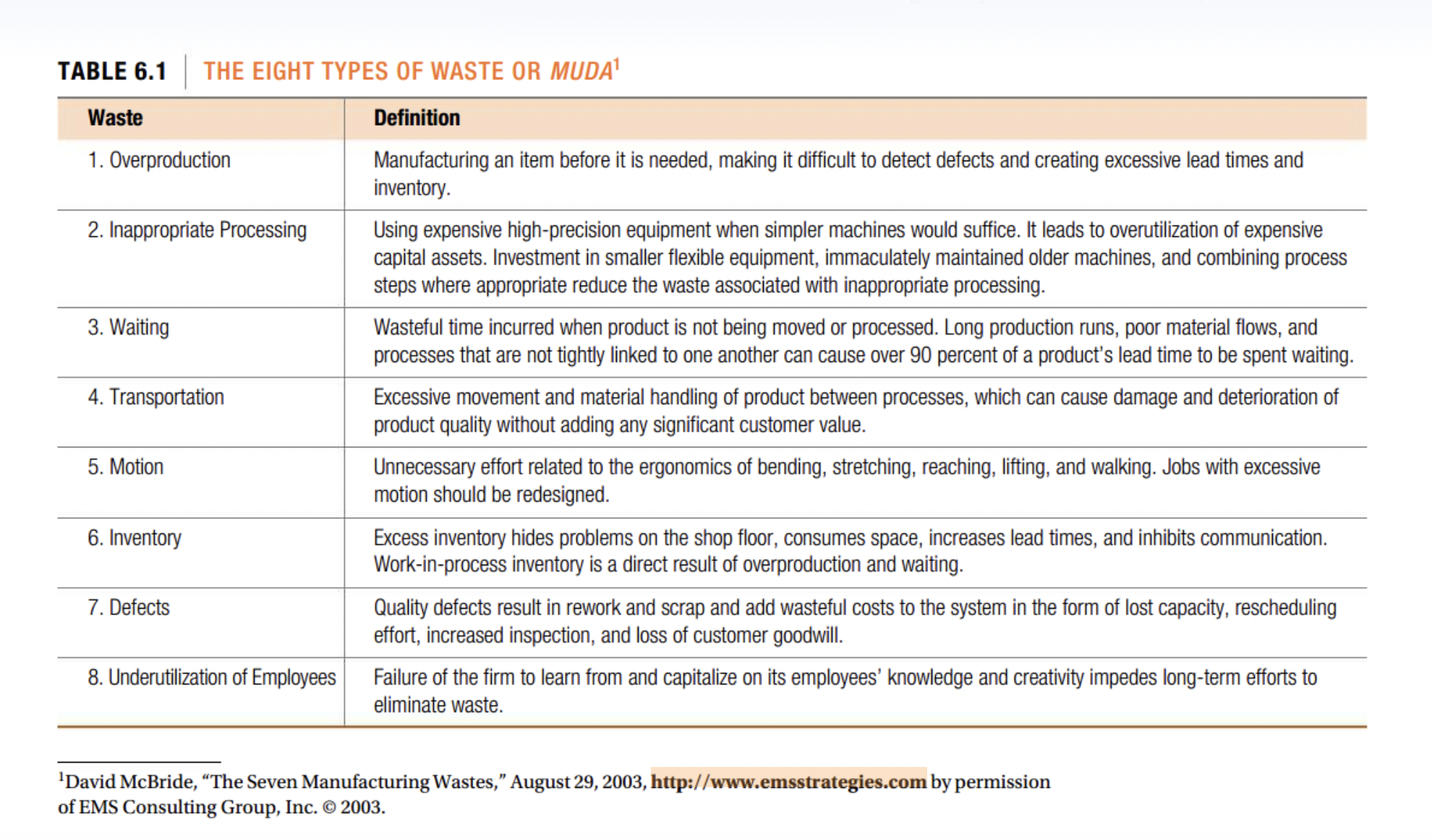

- Using a process you are familiar with it can be the same as above), explain in terms of a lean system the value added and non-value added (waste) activities. Relate the non-value activities to the eight types of waste shown in Table 6.1.

TABLE 6.1 THE EIGHT TYPES OF WASTE 0R MUD/l1 Waste 1. Overproduction Denition Manufacturing an item before it is needed, making it difcult to detect defects and creating excessive lead times and inventory. 2. Inappropriate Processing Using expensive high-precision equipment when simpler machines would suffice. it leads to overutilization of expensive capital assets. Investment in smaller flexible equipment, immaculately maintained older machines, and combining process steps where appropriate reduce the waste associated with inappropriate processing. 3. Waiting Wasteful time incurred when product is not being moved or processed. Long production runs, poor material flows, and processes that are not tightly linked to one another can cause over 90 percent of a product's lead time to be spent waiting. 4. Transportation Excessive movement and material handling of product between processes, which can cause damage and deterioration of product quality without adding any significant customer value. 5. Motion Unnecessary effort related to the ergonomics of bending, stretching, reaching, lifting, and walking. Jobs with excessive motion should be redesigned. 6. Inventory Excess inventory hides problems on the shop floor, consumes space. increases lead times, and inhibits communication. Work-in-process inventory is a direct result of overproduction and waiting. 7. Defects Quality defects result in rework and scrap and add wasteful costs to the system in the form of lost capacity, rescheduling effort, increased inspection, and loss of customer goodwill. 8. Underutilization of Employees Failure of the firm to learn from and capitalize on its employees' knowledge and creativity impedes longterm efforts to eliminate waste. lDavid McBride, \"The Seven Manufacturing Wastes." August 29, 2003, http://www.emssu'ategles.com by permission of EMS Consulting Group, Inc. 2003

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts