Question: USING ARENA 14 FOR SIMULATION NOT EXCEL A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system,

USING ARENA 14 FOR SIMULATION NOT EXCEL

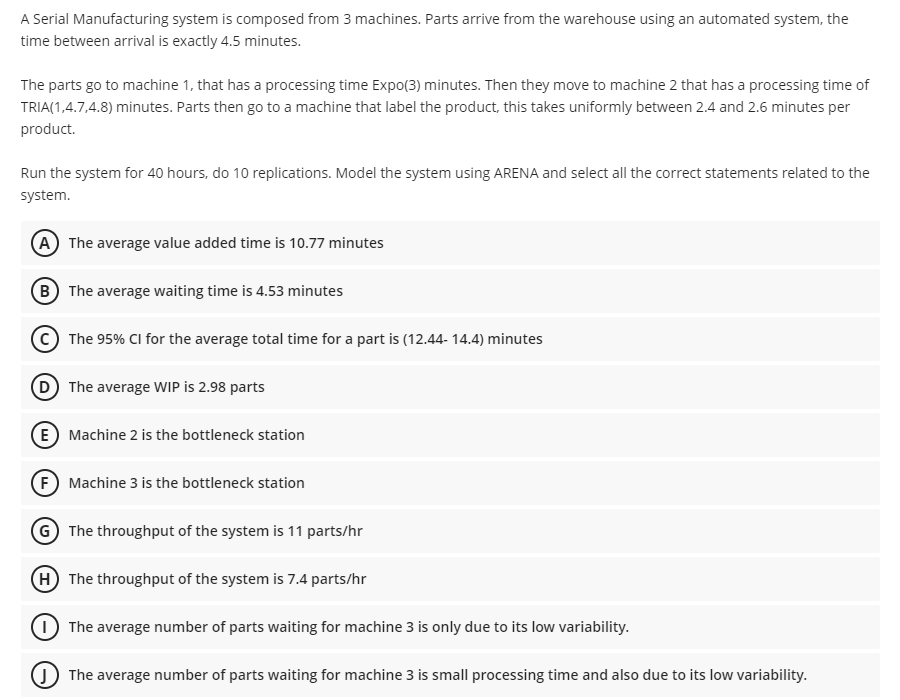

A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system, the time between arrival is exactly 4.5 minutes.

The parts go to machine 1, that has a processing time Expo(3) minutes. Then they move to machine 2 that has a processing time of TRIA(1,4.7,4.8) minutes. Parts then go to a machine that label the product, this takes uniformly between 2.4 and 2.6 minutes per product.

Run the system for 40 hours, do 10 replications. Model the system using ARENA and select all the correct statements related to the system.

A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system, the time between arrival is exactly 4.5 minutes. The parts go to machine 1, that has a processing time Expo(3) minutes. Then they move to machine 2 that has a processing time of TRIA(1,4.7,4.8) minutes. Parts then go to a machine that label the product, this takes uniformly between 2.4 and 2.6 minutes per product. Run the system for 40 hours, do 10 replications. Model the system using ARENA and select all the correct statements related to the system. A The average value added time is 10.77 minutes B The average waiting time is 4.53 minutes The 95% CI for the average total time for a part is (12.44- 14.4) minutes D The average WIP is 2.98 parts E Machine 2 is the bottleneck station Machine 3 is the bottleneck station G The throughput of the system is 11 parts/hr @ The throughput of the system is 7.4 parts/hr 0 The average number of parts waiting for machine 3 is only due to its low variability. The average number of parts waiting for machine 3 is small processing time and also due to its low variability. A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system, the time between arrival is exactly 4.5 minutes. The parts go to machine 1, that has a processing time Expo(3) minutes. Then they move to machine 2 that has a processing time of TRIA(1,4.7,4.8) minutes. Parts then go to a machine that label the product, this takes uniformly between 2.4 and 2.6 minutes per product. Run the system for 40 hours, do 10 replications. Model the system using ARENA and select all the correct statements related to the system. A The average value added time is 10.77 minutes B The average waiting time is 4.53 minutes The 95% CI for the average total time for a part is (12.44- 14.4) minutes D The average WIP is 2.98 parts E Machine 2 is the bottleneck station Machine 3 is the bottleneck station G The throughput of the system is 11 parts/hr @ The throughput of the system is 7.4 parts/hr 0 The average number of parts waiting for machine 3 is only due to its low variability. The average number of parts waiting for machine 3 is small processing time and also due to its low variability

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts