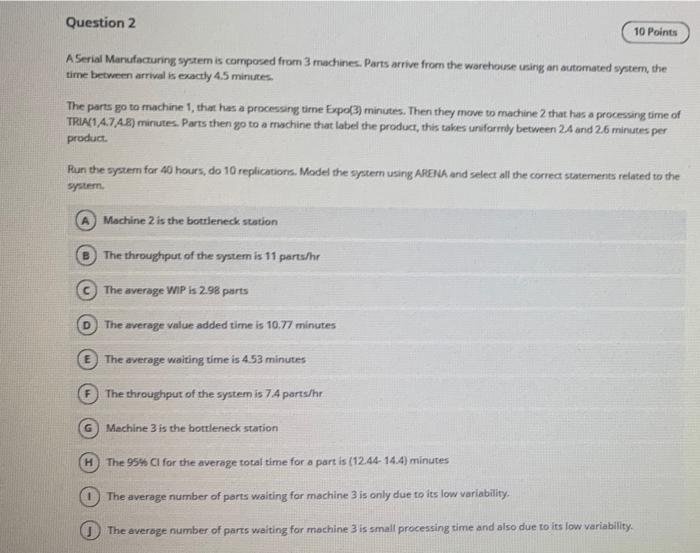

Question: Question 2 10 Points The A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system, the time

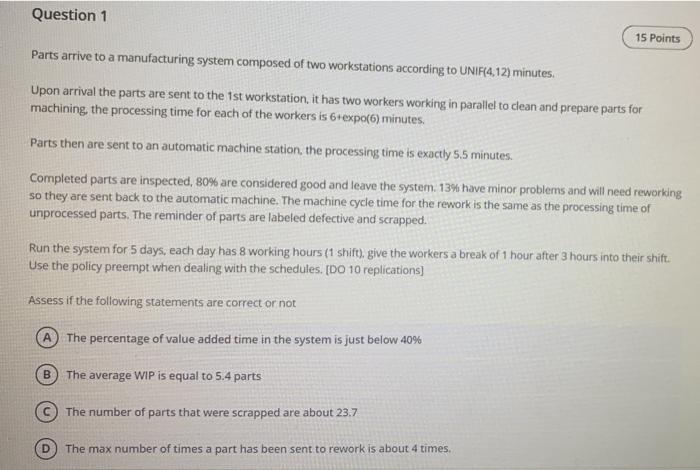

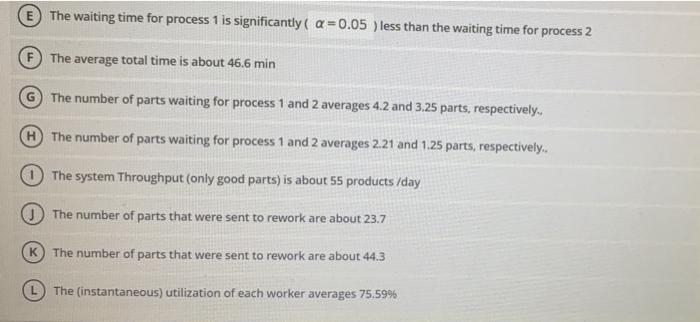

Question 2 10 Points The A Serial Manufacturing system is composed from 3 machines. Parts arrive from the warehouse using an automated system, the time between arrival is exactly 45 minutes. parts go to machine 1, that has a processing time Expo(3) minutes. Then they move to machine 2 that has a processing time of TRIA(1,4,748) minutes. Parts then go to a machine that label the product, this takes uniformly between 24 and 26 minutes per product Run the system for 40 hours, do 10 replications. Model the system using ARENA and select all the correct statements related to the system Machine 2 is the bottleneck station The throughput of the system is 11 parts/hr The average WIP is 2.98 parts The average value added time is 10.77 minutes The average waiting time is 4.53 minutes The throughput of the system is 7A ports/hr Machine 3 is the bottleneck station The 95% Cl for the average total time for a part is (12.44- 14.4) minutes The average number of parts waiting for machine 3 is only due to its low variability The average number of parts waiting for machine 3 is small processing time and also due to its low variability, Question 1 15 Points Parts arrive to a manufacturing system composed of two workstations according to UNIF(4,12) minutes, Upon arrival the parts are sent to the 1st workstation, it has two workers working in parallel to clean and prepare parts for machining the processing time for each of the workers is 6+ expo(6) minutes. Parts then are sent to an automatic machine station, the processing time is exactly 5.5 minutes. Completed parts are inspected, 80% are considered good and leave the system. 134 have minor problems and will need reworking so they are sent back to the automatic machine. The machine cycle time for the rework is the same as the processing time of unprocessed parts. The reminder of parts are labeled defective and scrapped. Run the system for 5 days, each day has 8 working hours (1 shift), give the workers a break of 1 hour after 3 hours into their shift. Use the policy preempt when dealing with the schedules. [DO 10 replications) Assess if the following statements are correct or not The percentage of value added time in the system is just below 40% B The average WIP is equal to 5.4 parts The number of parts that were scrapped are about 23.7 The max number of times a part has been sent to rework is about 4 times. The waiting time for process 1 is significantly ( a=0.05 ) less than the waiting time for process 2 The average total time is about 46.6 min The number of parts waiting for process 1 and 2 averages 4.2 and 3.25 parts, respectively.. The number of parts waiting for process 1 and 2 averages 2.21 and 1.25 parts, respectively, The system Throughput (only good parts) is about 55 products /day The number of parts that were sent to rework are about 23.7 K The number of parts that were sent to rework are about 44.3 The (instantaneous) utilization of each worker averages 75,599