Question: Using the current and alternative supplier information that has been provided for FY2021, and the weights to be considered for each supplier characteristic, you are

Using the current and alternative supplier information that has been provided for FY2021, and the weights to be considered for each supplier characteristic, you are to develop a supplier scorecard using the following scale: 3 = best, 2 = second best, 1 = worst. As you first look over the information that has been provided, you will note that the values for the Quality Capability Index (Cpk) for the current and alternative suppliers are listed as TBD* (to be determined).

a.Using the Quality Performance Information that has been provided, calculate the values of Cpk for each of the current and alternative suppliers. Please show your work. Based on these values, which supplier would rate as best? Second best? Worst?

b.Using the ratings from 1-3 for each of the supplier characteristics and also the weight to be applied to each supplier characteristic, which supplier would you recommend be used? Be sure to show your completed supplier scorecard and your calculations.

c.What other factors do you feel might be helpful in making your decision?

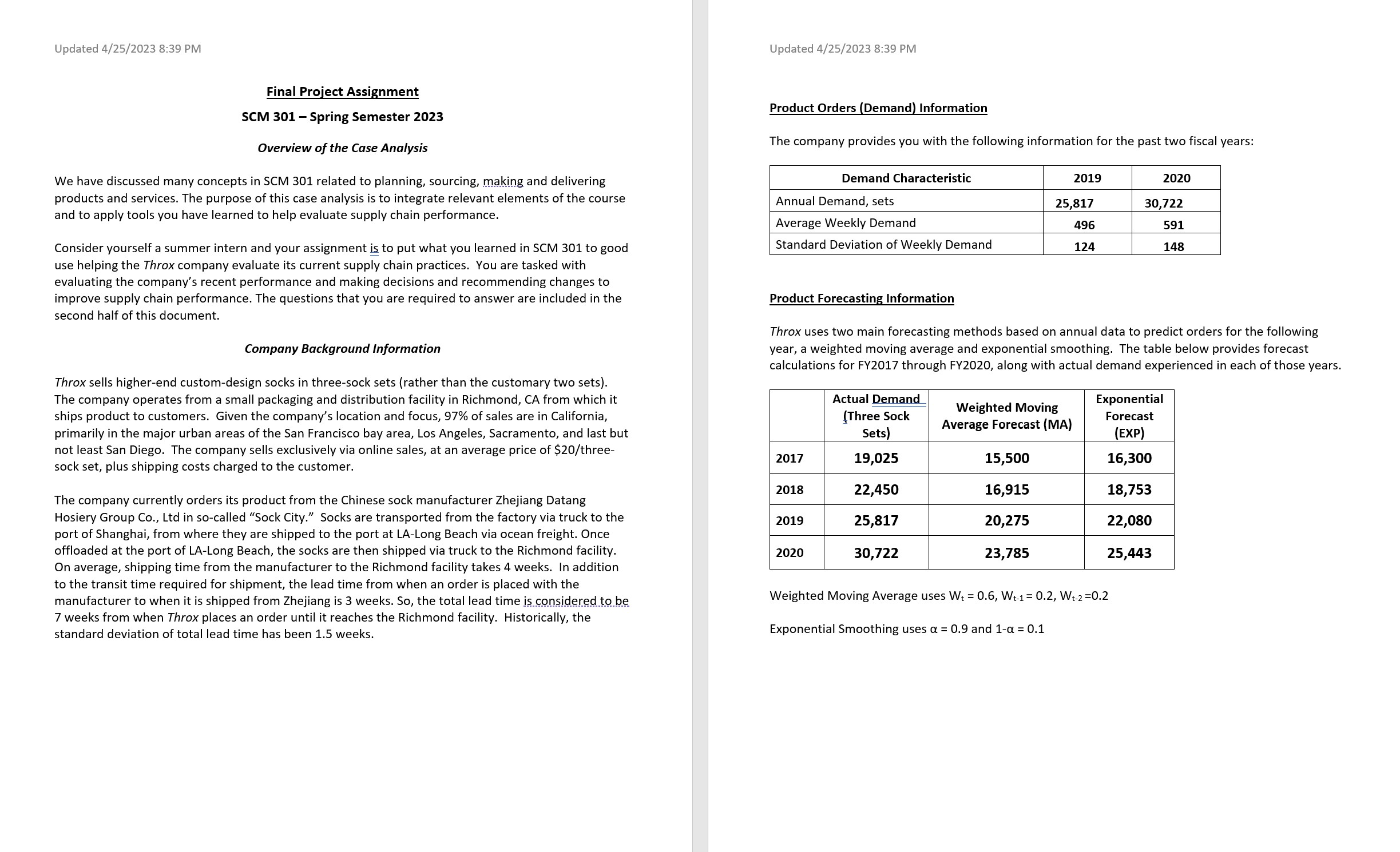

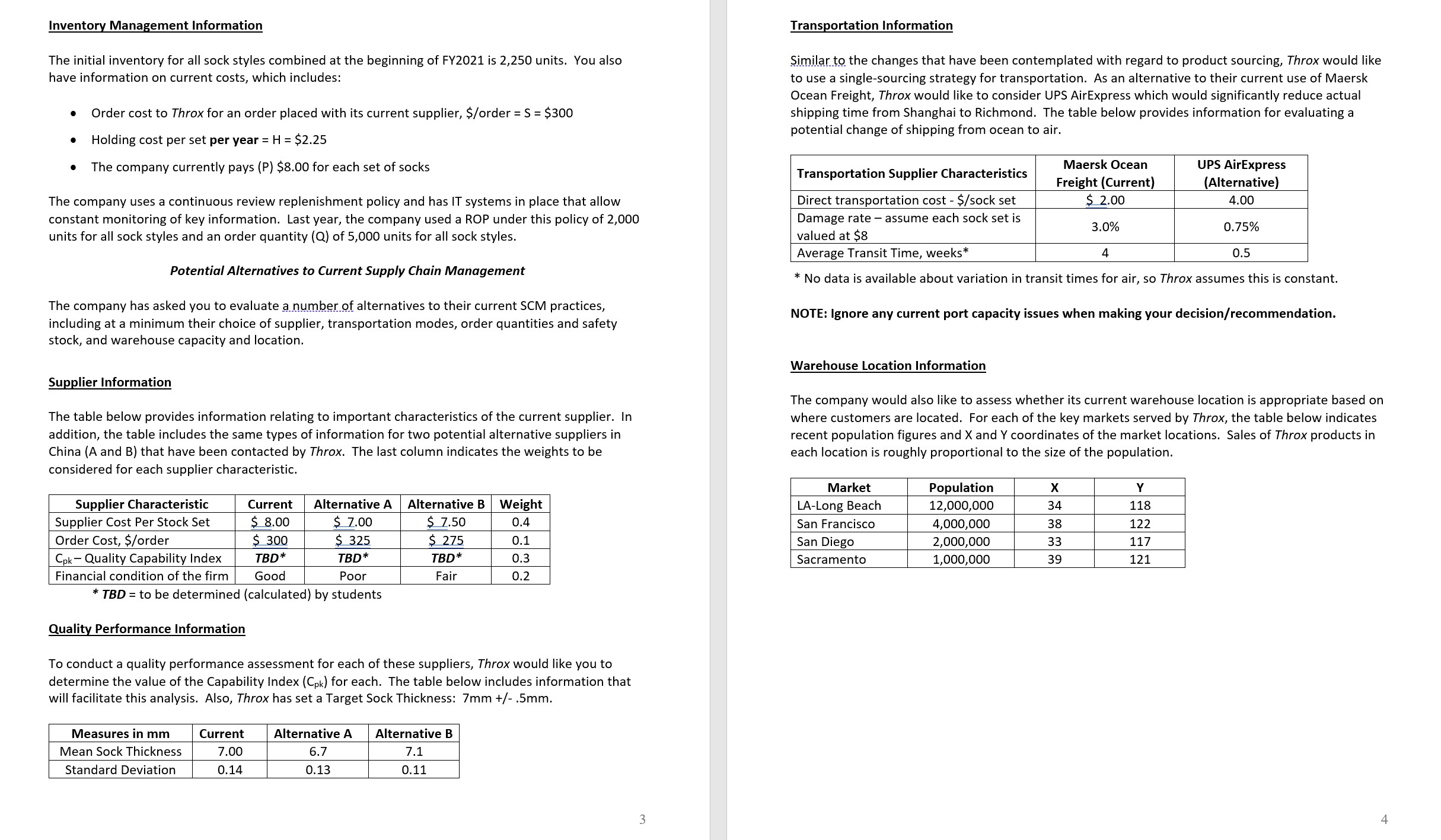

Final Project Assignment Product Orders (Demand) Information SCM 301 - Spring Semester 2023 Overview of the Case Analysis The company provides you with the following information for the past two fiscal years: We have discussed many concepts in SCM 301 related to planning, sourcing, making and delivering products and services. The purpose of this case analysis is to integrate relevant elements of the course and to apply tools you have learned to help evaluate supply chain performance. Consider yourself a summer intern and your assignment is to put what you learned in SCM 301 to good use helping the Throx company evaluate its current supply chain practices. You are tasked with evaluating the company's recent performance and making decisions and recommending changes to improve supply chain performance. The questions that you are required to answer are included in the Product Forecasting Information second half of this document. Throx uses two main forecasting methods based on annual data to predict orders for the following Company Background Information year, a weighted moving average and exponential smoothing. The table below provides forecast calculations for FY2017 through FY2020, along with actual demand experienced in each of those years. Throx sells higher-end custom-design socks in three-sock sets (rather than the customary two sets). The company operates from a small packaging and distribution facility in Richmond, CA from which it ships product to customers. Given the company's location and focus, 97% of sales are in California, primarily in the major urban areas of the San Francisco bay area, Los Angeles, Sacramento, and last but not least San Diego. The company sells exclusively via online sales, at an average price of $20/ threesock set, plus shipping costs charged to the customer. The company currently orders its product from the Chinese sock manufacturer Zhejiang Datang Hosiery Group Co., Ltd in so-called "Sock City." Socks are transported from the factory via truck to the port of Shanghai, from where they are shipped to the port at LA-Long Beach via ocean freight. Once offloaded at the port of LA-Long Beach, the socks are then shipped via truck to the Richmond facility. On average, shipping time from the manufacturer to the Richmond facility takes 4 weeks. In addition to the transit time required for shipment, the lead time from when an order is placed with the manufacturer to when it is shipped from Zhejiang is 3 weeks. So, the total lead time is considered to be Weighted Moving Average uses Wt=0.6,Wt1=0.2,Wt2=0.2 7 weeks from when Throx places an order until it reaches the Richmond facility. Historically, the standard deviation of total lead time has been 1.5 weeks. Exponential Smoothing uses =0.9 and 1=0.1 Inventory Management Information Transportation Information The initial inventory for all sock styles combined at the beginning of FY2021 is 2,250 units. You also Similar to the changes that have been contemplated with regard to product sourcing, Throx would like have information on current costs, which includes: to use a single-sourcing strategy for transportation. As an alternative to their current use of Maersk Ocean Freight, Throx would like to consider UPS AirExpress which would significantly reduce actual - Order cost to Throx for an order placed with its current supplier, $/ order =S=$300 shipping time from Shanghai to Richmond. The table below provides information for evaluating a - Holding cost per set per year =H=$2.25 potential change of shipping from ocean to air. - The company currently pays (P) $8.00 for each set of socks The company uses a continuous review replenishment policy and has IT systems in place that allow constant monitoring of key information. Last year, the company used a ROP under this policy of 2,000 units for all sock styles and an order quantity (Q) of 5,000 units for all sock styles. Potential Alternatives to Current Supply Chain Management * No data is available about variation in transit times for air, so Throx assumes this is constant. The company has asked you to evaluate a number of alternatives to their current SCM practices, NOTE: Ignore any current port capacity issues when making your decision/recommendation. including at a minimum their choice of supplier, transportation modes, order quantities and safety stock, and warehouse capacity and location. Warehouse Location Information Supplier Information The company would also like to assess whether its current warehouse location is appropriate based on The table below provides information relating to important characteristics of the current supplier. In where customers are located. For each of the key markets served by Throx, the table below indicates addition, the table includes the same types of information for two potential alternative suppliers in recent population figures and X and Y coordinates of the market locations. Sales of Throx products in China ( A and B ) that have been contacted by Throx. The last column indicates the weights to be each location is roughly proportional to the size of the population. considered for each supplier characteristic. BE= to be determined (calculated) by students Quality Performance Information To conduct a quality performance assessment for each of these suppliers, Throx would like you to determine the value of the Capability Index (Cpk) for each. The table below includes information that will facilitate this analysis. Also, Throx has set a Target Sock Thickness: 7mm+/.5mm

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts