Question: Using the operating data given below and the information from the feed heater drawing and property data from HYSYS glycol package calculate 1.calculate the duty

Using the operating data given below and the information from the feed heater drawing and property data from HYSYS glycol package calculate

1.calculate the duty and required steam rate

2. calculate the expected capacity (Btu/h) for the heat exchanger as it exists now and the change if one of the u-tubes is blocked.

3. what is the increase in capacity expected if the heat exchanger is cleaned to its original new state.

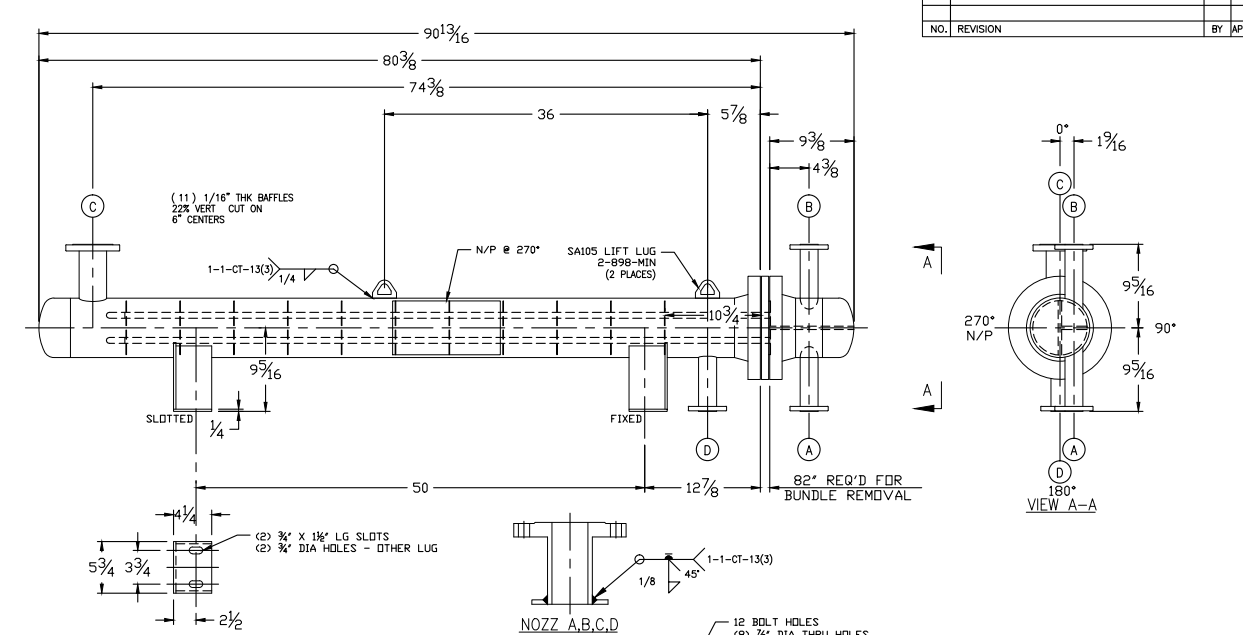

Operating parameters: 40% w/w propylene glycol in DI water, 5 gpm at 70F, heat exchanger inlet: 120F, at exchanger outlet: saturated liquid at 15psig. saturated steam is available at 75 psig. Fouling: inside 0.02 hft2F/Btu, inside 0.01 hft2F/Btu (note: this is heavy fouling)

You can use exchanger geometry of existing exchanger: 1 shell pass, even number of tube passes, 5/8 in BWG 16 74 in tubes, 25/32 in spacing. you can use different pitch, geometry, and different number of tubes, different baffle spacing if needed

show all calculations. You can use a spreadsheet if desired, but write in the formulas that you use.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts