Question: Value - stream mapping at PlastiPharm is a once - a - year effort that is conducted by senior management at a high level. Because

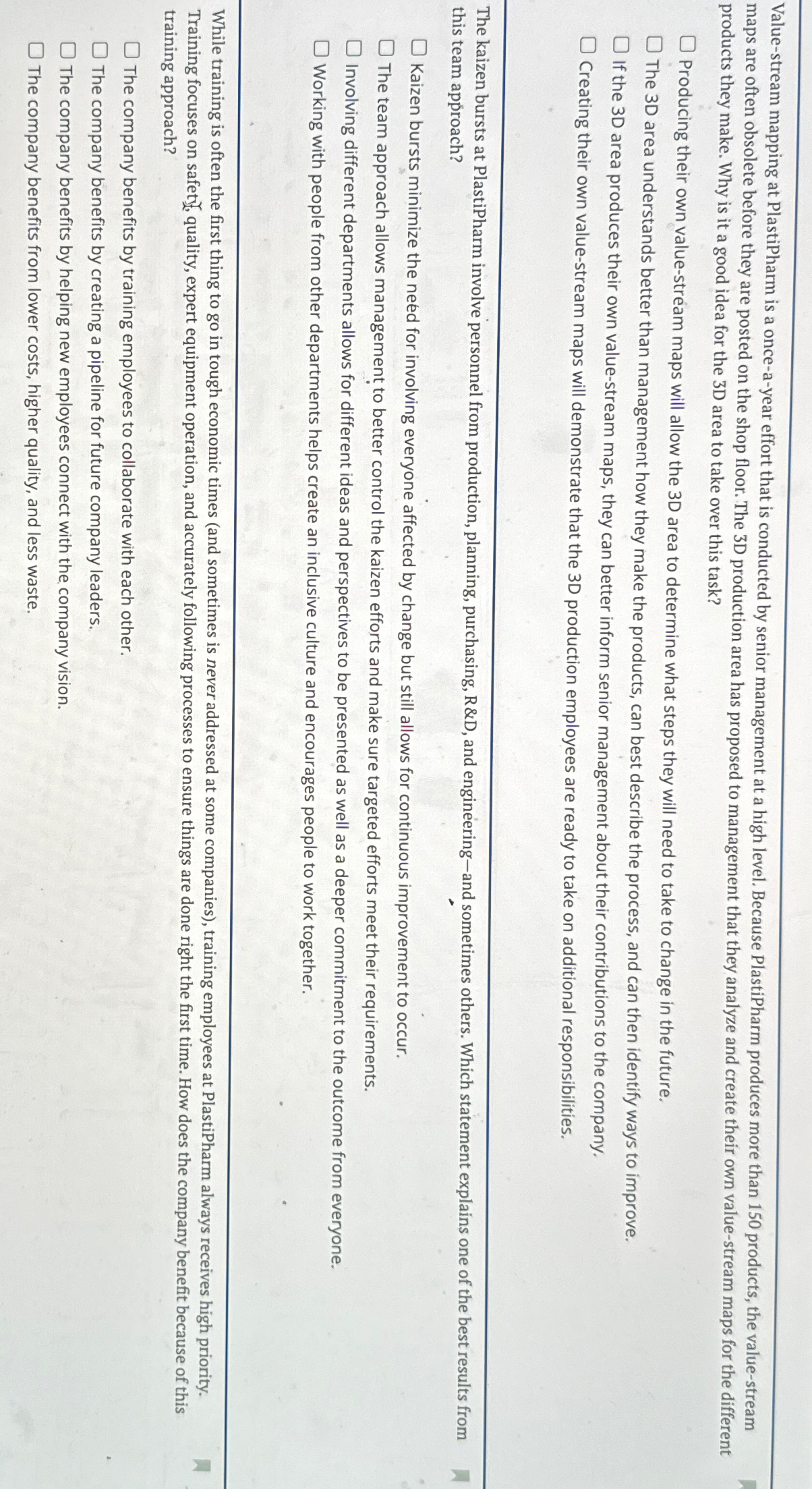

Valuestream mapping at PlastiPharm is a onceayear effort that is conducted by senior management at a high level. Because PlastiPharm produces more than products, the valuestream maps are often obsolete before they are posted on the shop floor. The D production area has proposed to management that they analyze and create their own valuestream maps for the different products they make. Why is it a good idea for the D area to take over this task?

Producing their own valuestream maps will allow the D area to determine what steps they will need to take to change in the future.

The D area understands better than management how they make the products, can best describe the process, and can then identify ways to improve.

If the D area produces their own valuestream maps, they can better inform senior management about their contributions to the company.

Creating their own valuestream maps will demonstrate that the D production employees are ready to take on additional responsibilities.

The kaizen bursts at PlastiPharm involve personnel from production, planning, purchasing, R&D and engineeringand sometimes others. Which statement explains one of the best results from this team approach?

Kaizen bursts minimize the need for involving everyone affected by change but still allows for continuous improvement to occur.

The team approach allows management to better control the kaizen efforts and make sure targeted efforts meet their requirements.

Involving different departments allows for different ideas and perspectives to be presented as well as a deeper commitment to the outcome from everyone.

Working with people from other departments helps create an inclusive culture and encourages people to work together.

While training is often the first thing to go in tough economic times and sometimes is never addressed at some companies training employees at PlastiPharm always receives high priority. Training focuses on safet y quality, expert equipment operation, and accurately following processes to ensure things are done right the first time. How does the company benefit because of this training approach?

The company benefits by training employees to collaborate with each other.

The company benefits by creating a pipeline for future company leaders.

The company benefits by helping new employees connect with the company vision.

The company benefits from lower costs, higher quality, and less waste.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock