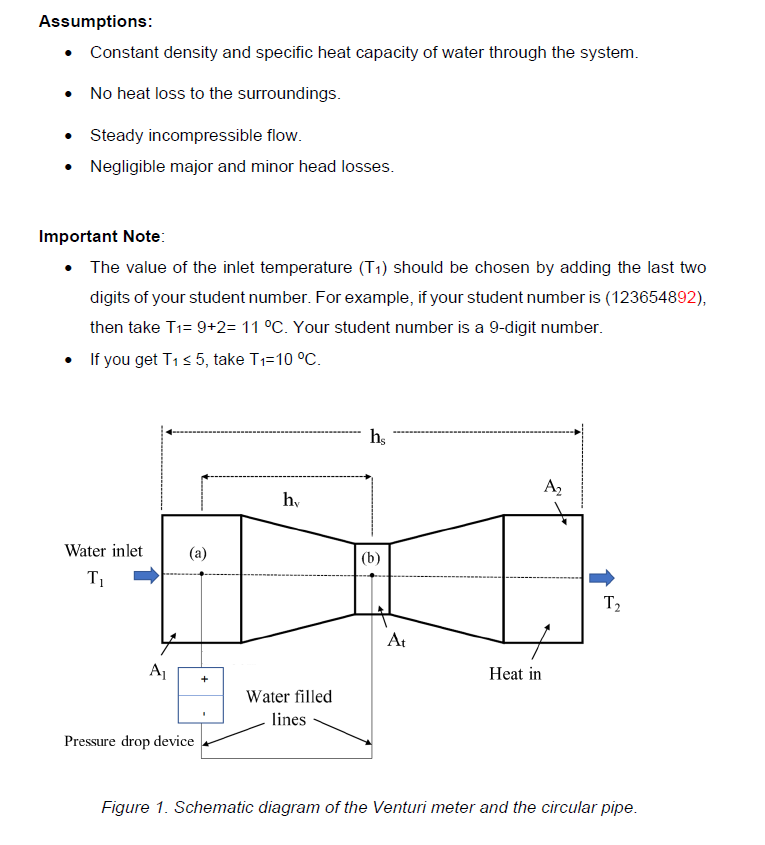

Question: Water flows through a horizontal system comprising a Venturi flow meter in series with a circular pipe (see Fig. 1). The cross-sectional areas of the

Water flows through a horizontal system comprising a Venturi flow meter in series with a circular pipe (see Fig. 1). The cross-sectional areas of the Venturi inlet and the throat are A1 and At, respectively. Heat is supplied to the water in the cylindrical pipe at a rate of 486kW. The inlet temperature of the water in the system is T1 and the outlet temperature of the system is 75C. Assumptions: - Constant density and specific heat capacity of water through the system. - No heat loss to the surroundings. - Steady incompressible flow. - Negligible major and minor head losses. Important Note: - The value of the inlet temperature (T1) should be chosen by adding the last two digits of your student number. For example, if your student number is (123654892), then take T1=9+2=11C. Your student number is a 9-digit number. - If you get T15, take T1=10C. Figure 1. Schematic diagram of the Venturi meter and the circular pipe. 1. Provide a brief discussion to outline the applications of Bernoulli's principle in Chemical Engineering, (Max. 500 words). All sources of information should be well cited using Harvard-Hull referencing style. [10 mark] 2. Calculate the pressure drop (P) in Pascals between the Venturi inlet and the throat and calculate the water velocity at the Venturi throat. [13 mark] 3. Use the data obtained in part (2) to redesign the throat of the Venturi meter (i.e. calculating the new throat diameter) so that the velocity at the Venturi throat is half of that obtained in part (2). [8 mark] 4. Provide a brief discussion to explain the purpose of a discharge coefficient Cd in a flow rate calculation of the Venturi flow meter (Max. 200 words). [5 mark] 5. If your line manager asked you to select a proper flow measurement for wastewater (sewage) flow, containing solid contaminants. Three flow meters are available to select from: (i) turbine flowmeter, (ii) multi-holes orifice meter, and (iii) Venturi meter. Provide a brief discussion to explain the most suitable flow meter in terms of measurement accuracy, cost, and durability, with a clear justification. (Max. 500 words). [10 mark] Data: - Water density: 998kg/m3. - Specific heat capacity of water: 4180J/kgC. - Venturi inlet and throat diameters: 115mm and 40mm, respectively. - Venturi discharge coefficient: 0.965 Water flows through a horizontal system comprising a Venturi flow meter in series with a circular pipe (see Fig. 1). The cross-sectional areas of the Venturi inlet and the throat are A1 and At, respectively. Heat is supplied to the water in the cylindrical pipe at a rate of 486kW. The inlet temperature of the water in the system is T1 and the outlet temperature of the system is 75C. Assumptions: - Constant density and specific heat capacity of water through the system. - No heat loss to the surroundings. - Steady incompressible flow. - Negligible major and minor head losses. Important Note: - The value of the inlet temperature (T1) should be chosen by adding the last two digits of your student number. For example, if your student number is (123654892), then take T1=9+2=11C. Your student number is a 9-digit number. - If you get T15, take T1=10C. Figure 1. Schematic diagram of the Venturi meter and the circular pipe. 1. Provide a brief discussion to outline the applications of Bernoulli's principle in Chemical Engineering, (Max. 500 words). All sources of information should be well cited using Harvard-Hull referencing style. [10 mark] 2. Calculate the pressure drop (P) in Pascals between the Venturi inlet and the throat and calculate the water velocity at the Venturi throat. [13 mark] 3. Use the data obtained in part (2) to redesign the throat of the Venturi meter (i.e. calculating the new throat diameter) so that the velocity at the Venturi throat is half of that obtained in part (2). [8 mark] 4. Provide a brief discussion to explain the purpose of a discharge coefficient Cd in a flow rate calculation of the Venturi flow meter (Max. 200 words). [5 mark] 5. If your line manager asked you to select a proper flow measurement for wastewater (sewage) flow, containing solid contaminants. Three flow meters are available to select from: (i) turbine flowmeter, (ii) multi-holes orifice meter, and (iii) Venturi meter. Provide a brief discussion to explain the most suitable flow meter in terms of measurement accuracy, cost, and durability, with a clear justification. (Max. 500 words). [10 mark] Data: - Water density: 998kg/m3. - Specific heat capacity of water: 4180J/kgC. - Venturi inlet and throat diameters: 115mm and 40mm, respectively. - Venturi discharge coefficient: 0.965

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts