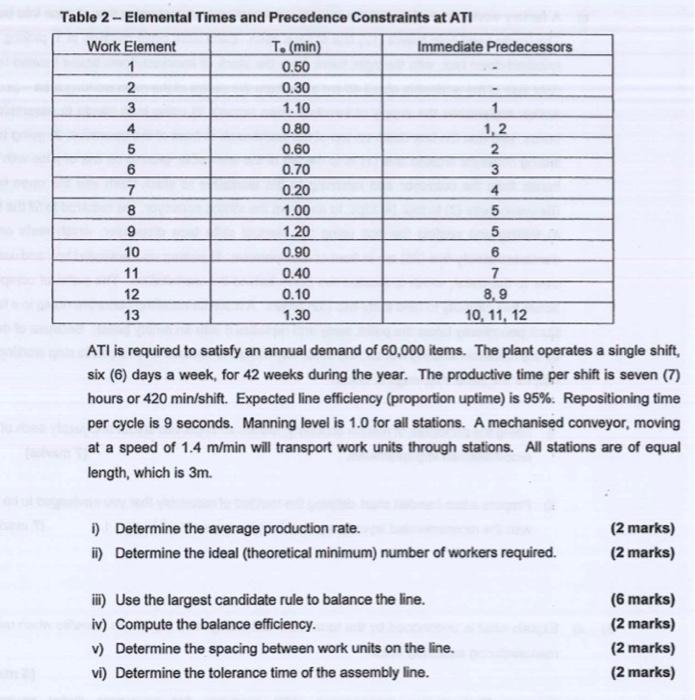

Question: work study pls answer all parts Advance Technologies Incorporated (ATI) produces flat consumer digital equipment. Elemental times and precedence constraints that must be satisfied for

work study pls answer all parts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock