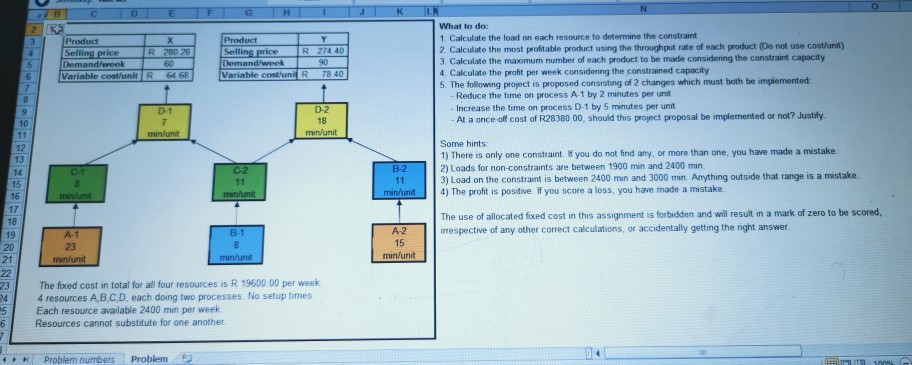

Question: XY enterprise process map G H K 2 3 E + Product Selling price R280 28 Demand/week 60 Variable cost/unit R 64 68 Product Y

XY enterprise process map

G H K 2 3 E + Product Selling price R280 28 Demand/week 60 Variable cost/unit R 64 68 Product Y Selling price R 274 40 Demand week 90 Variable costun R 78 40 5 LN What to do: 1. Calculate the load on each resource to determine the constraint 2. Calculate the most profitable product using the throughput rate of each product (Do not use costunit) 3. Calculate the maximum number of each product to be made considering the constraint capacity 4. Calculate the profit per week considering the constrained capacity 5. The following project is proposed consisting of 2 changes which must both be implemented Reduce the time on process A-1 by 2 minutes per unit Increase the time on process D-1 by 5 minutes per unit At a once-off cost of R2838000, should this project proposal be implemented or not? Justify 7 8 D-1 7 min/unit D-2 18 min/unit C2 11 B-2 11 min/unit Some hints 1) There is only one constraint. If you do not find any, or more than one, you have made a mistake. 2) Leads for non-constraints are between 1900 min and 2400 min 3) Load on the constraint is between 2400 min and 3000 min. Anything outside that range is a mistake 4) The profit is positive. If you score a loss, you have made a mistake. 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 6 The use of allocated fixed cost in this assignment is forbidden and will result in a mark of zero to be scored, irrespective of any other correct calculations, or accidentally getting the right answer A1 23 min/unit B-1 8 min/und 15 min/unit The fixed cost in total for all four resources is R 1960000 per week 4 resources A,B,C,D. each doing two processes. No setup times Each resource available 2400 min per week Resources cannot substitute for one another 3 CH Problem numbers Problem ing G H K 2 3 E + Product Selling price R280 28 Demand/week 60 Variable cost/unit R 64 68 Product Y Selling price R 274 40 Demand week 90 Variable costun R 78 40 5 LN What to do: 1. Calculate the load on each resource to determine the constraint 2. Calculate the most profitable product using the throughput rate of each product (Do not use costunit) 3. Calculate the maximum number of each product to be made considering the constraint capacity 4. Calculate the profit per week considering the constrained capacity 5. The following project is proposed consisting of 2 changes which must both be implemented Reduce the time on process A-1 by 2 minutes per unit Increase the time on process D-1 by 5 minutes per unit At a once-off cost of R2838000, should this project proposal be implemented or not? Justify 7 8 D-1 7 min/unit D-2 18 min/unit C2 11 B-2 11 min/unit Some hints 1) There is only one constraint. If you do not find any, or more than one, you have made a mistake. 2) Leads for non-constraints are between 1900 min and 2400 min 3) Load on the constraint is between 2400 min and 3000 min. Anything outside that range is a mistake 4) The profit is positive. If you score a loss, you have made a mistake. 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 6 The use of allocated fixed cost in this assignment is forbidden and will result in a mark of zero to be scored, irrespective of any other correct calculations, or accidentally getting the right answer A1 23 min/unit B-1 8 min/und 15 min/unit The fixed cost in total for all four resources is R 1960000 per week 4 resources A,B,C,D. each doing two processes. No setup times Each resource available 2400 min per week Resources cannot substitute for one another 3 CH Problem numbers Problem ingStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock