Question: You, a process design engineer, are tasked to build a powerplant that utilizes 1.5 metric tons of municipal solid wastes (MSW) per hour. In an

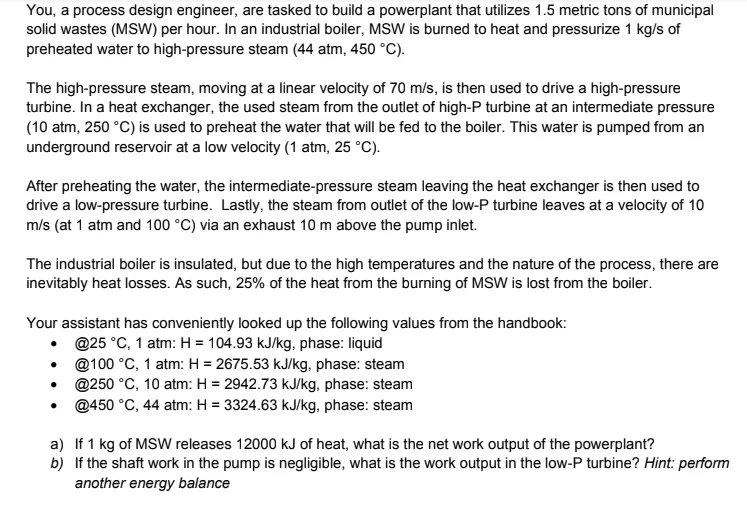

You, a process design engineer, are tasked to build a powerplant that utilizes 1.5 metric tons of municipal solid wastes (MSW) per hour. In an industrial boiler, MSW is burned to heat and pressurize 1 kg/s of preheated water to high-pressure steam (44 atm, 450 C). The high-pressure steam, moving at a linear velocity of 70 m/s, is then used to drive a high-pressure turbine. In a heat exchanger, the used steam from the outlet of high-P turbine at an intermediate pressure (10 atm, 250 C) is used to preheat the water that will be fed to the boiler. This water is pumped from an underground reservoir at a low velocity (1 atm, 25 C). After preheating the water, the intermediate-pressure steam leaving the heat exchanger is then used to drive a low-pressure turbine. Lastly, the steam from outlet of the low-P turbine leaves at a velocity of 10 m/s (at 1 atm and 100 C) via an exhaust 10 m above the pump inlet. The industrial boiler is insulated, but due to the high temperatures and the nature of the process, there are inevitably heat losses. As such, 25% of the heat from the burning of MSW is lost from the boiler. Your assistant has conveniently looked up the following values from the handbook: @25 C, 1 atm: H = 104.93 kJ/kg, phase: liquid @100 C, 1 atm: H = 2675.53 kJ/kg, phase: steam @250 C, 10 atm: H = 2942.73 kJ/kg, phase: steam @450 C, 44 atm: H = 3324.63 kJ/kg, phase: steam . . . a) If 1 kg of MSW releases 12000 kJ of heat, what is the net work output of the powerplant? b) If the shaft work in the pump is negligible, what is the work output in the low-P turbine? Hint: perform another energy balance You, a process design engineer, are tasked to build a powerplant that utilizes 1.5 metric tons of municipal solid wastes (MSW) per hour. In an industrial boiler, MSW is burned to heat and pressurize 1 kg/s of preheated water to high-pressure steam (44 atm, 450 C). The high-pressure steam, moving at a linear velocity of 70 m/s, is then used to drive a high-pressure turbine. In a heat exchanger, the used steam from the outlet of high-P turbine at an intermediate pressure (10 atm, 250 C) is used to preheat the water that will be fed to the boiler. This water is pumped from an underground reservoir at a low velocity (1 atm, 25 C). After preheating the water, the intermediate-pressure steam leaving the heat exchanger is then used to drive a low-pressure turbine. Lastly, the steam from outlet of the low-P turbine leaves at a velocity of 10 m/s (at 1 atm and 100 C) via an exhaust 10 m above the pump inlet. The industrial boiler is insulated, but due to the high temperatures and the nature of the process, there are inevitably heat losses. As such, 25% of the heat from the burning of MSW is lost from the boiler. Your assistant has conveniently looked up the following values from the handbook: @25 C, 1 atm: H = 104.93 kJ/kg, phase: liquid @100 C, 1 atm: H = 2675.53 kJ/kg, phase: steam @250 C, 10 atm: H = 2942.73 kJ/kg, phase: steam @450 C, 44 atm: H = 3324.63 kJ/kg, phase: steam . . . a) If 1 kg of MSW releases 12000 kJ of heat, what is the net work output of the powerplant? b) If the shaft work in the pump is negligible, what is the work output in the low-P turbine? Hint: perform another energy balance

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts