Question: You have accepted a position as a Manufacturing Engineer at a Plastics Manufacturer. You do not have prior injection moulding experience. The firm would like

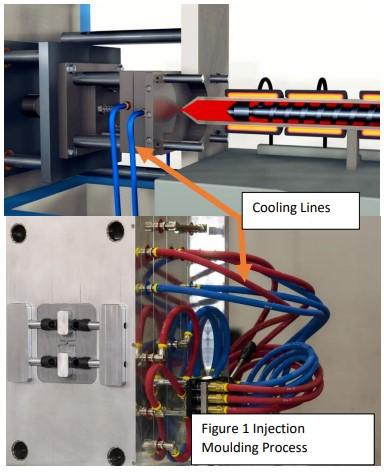

You have accepted a position as a Manufacturing Engineer at a Plastics Manufacturer. You do not have prior injection moulding experience. The firm would like to understand better how to design optimal cooling in injection moulding. Their initial review of the technical literature suggests that optimized mould cooling reduces defects, rework, and material waste risks. It is well-known in the literature that optimized cooling transfers heat away from the mould and maintains a stable cooling rate. The firm wants to stay with its present design using water cooling, whereby a pump circulates water outside the mold cavity, as shown in Figure 1.

a. Your manager would like to use the LAMDA cycle to generate knowledge about the cooling process and its impact on part quality. He mentions that part quality means geometric quality/warping, weight (short shots), and porosity %. Your role as an Engineer is to learn how/where to find quality characteristics the company monitors (i.e., quality data card).

The LAMBDA exercise is an excellent opportunity to learn about the process. To ensure success, you should lay out the framework of LAMDA and describe each stage. Your manager believes that cooling line diameter, length, cavity material, pump flow rate, working fluid temperature, and flow pressure could influence the cooling process and, thus, part quality. Your manager hopes that your modeling stage will be comprehensive enough (employing different methods/techniques/experiments) to understand better the effect of various cooling parameters on part quality. So, in answering this question correctly, demonstrate to your manager how LAMDA allows you to generate knowledge by describing details of every stage of the process.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts