Question: You have accepted a position as a Manufacturing Engineer at a Plastics Manufacturer. You do not have prior injection moulding experience. The firm would like

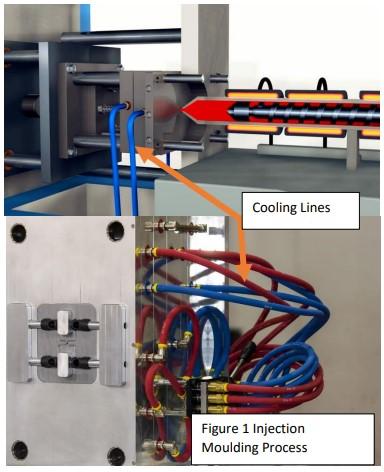

You have accepted a position as a Manufacturing Engineer at a Plastics Manufacturer. You do not have prior injection moulding experience. The firm would like to understand better how to design optimal cooling in injection moulding. Their initial review of the technical literature suggests that optimized mould cooling reduces defects, rework, and material waste risks. It is well-known in the literature that optimized cooling transfers heat away from the mould and maintains a stable cooling rate. The firm wants to stay with its present design using water cooling, whereby a pump circulates water outside the mold cavity, as shown in Figure 1.

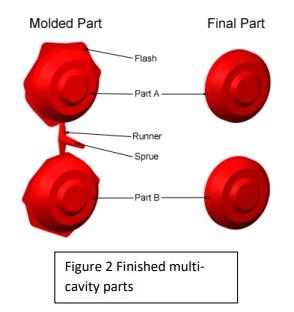

b. Your manager was rather impressed with your work. He remembered you have experience with Jidoka and asked if you would consider another project. The company had just purchased a 500-ton injection mould machine/multi-cavity mould capable of producing two parts per production cycle (Figure 2). Post-processing is required, including trimming the runner, sprue, and any flashing that has occurred. The problem he faces is that operators across different shifts do not trim the excess plastic consistently, and, worse, operators miss trimming before tossing it into a bin. He would like to focus on prevention and not just detection. Deploy the Jidoka process and explain all stages specific to this problem.

c. In reference to part b, if the production process time is 2.49 min and it takes 35 seconds to trim the excess plastic calculate the cycle time per part for the workstation. If the customer requires 300 pieces per day based on 420 min of available production time, do you have a bottleneck or overproduction at the station? Sketch a takt time/cycle time chart showing the imbalance of the production line if you separate moulding from trimming. Based on the two workstations, do you have an overproduction or a bottleneck? Redraw the takt time/cycle time chart with the two workstations assuming you have a three-mould cavity with a processing time of 4.2 min and 1.2 min for trimming. Is there an improvement? Explain. Your manager also mentions that after trimming, there is a processing cycle time for 1 min/part of cleaning. Knowing this, how many workstations should you have for a perfectly balanced line considering the three-mould cavity processing?

Molded Part Final Part Figure 2 Finished multicavity parts

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts