Question: . Your task is to continue the case study, and write a short report (1 page or less) including calculations to show how you would

. Your task is to continue the case study, and write a short report (1 page or less) including calculations to show how you would rebalance the process (if possible) to make the specialization setup more efficient (relative to the scenario where each work works independently). Please recalculate each process metric and describe your recommendation using these metrics (and any additional metrics as needed).

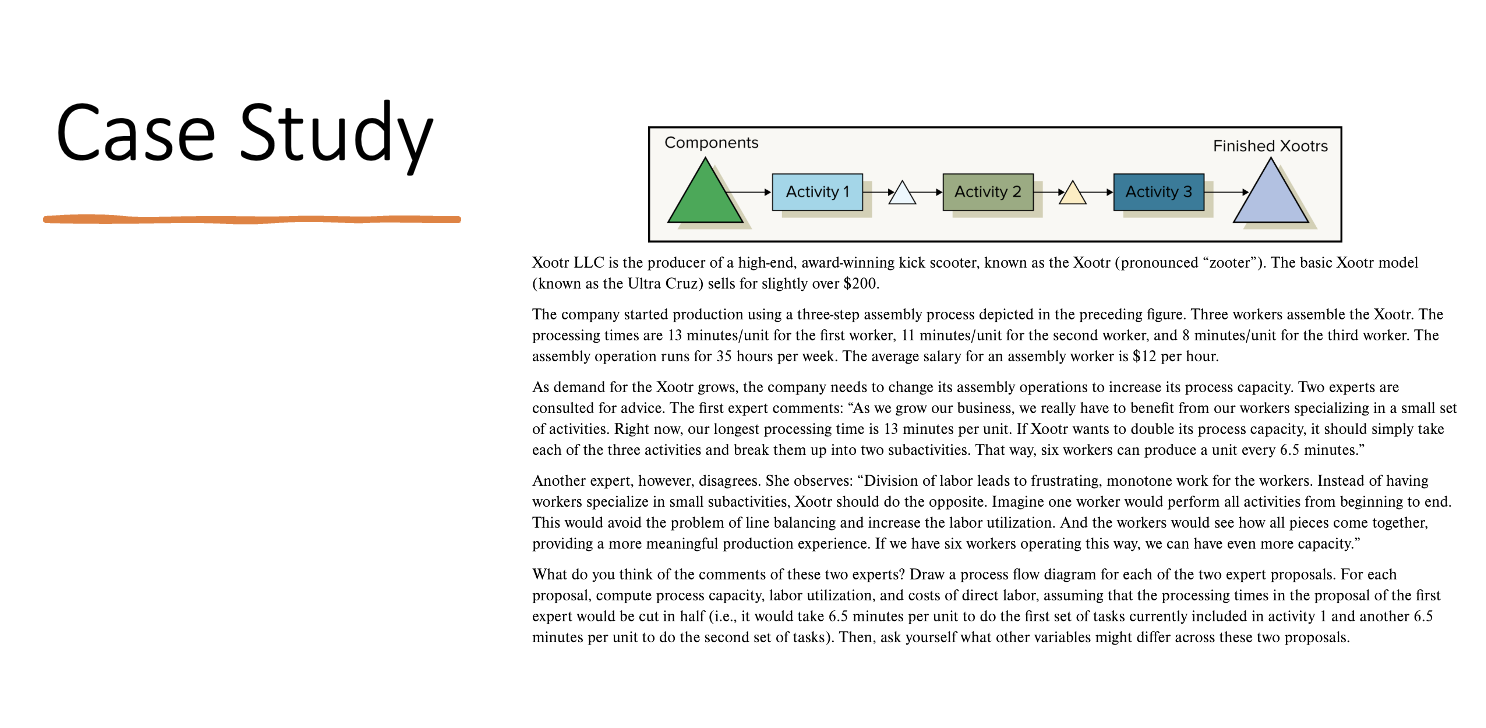

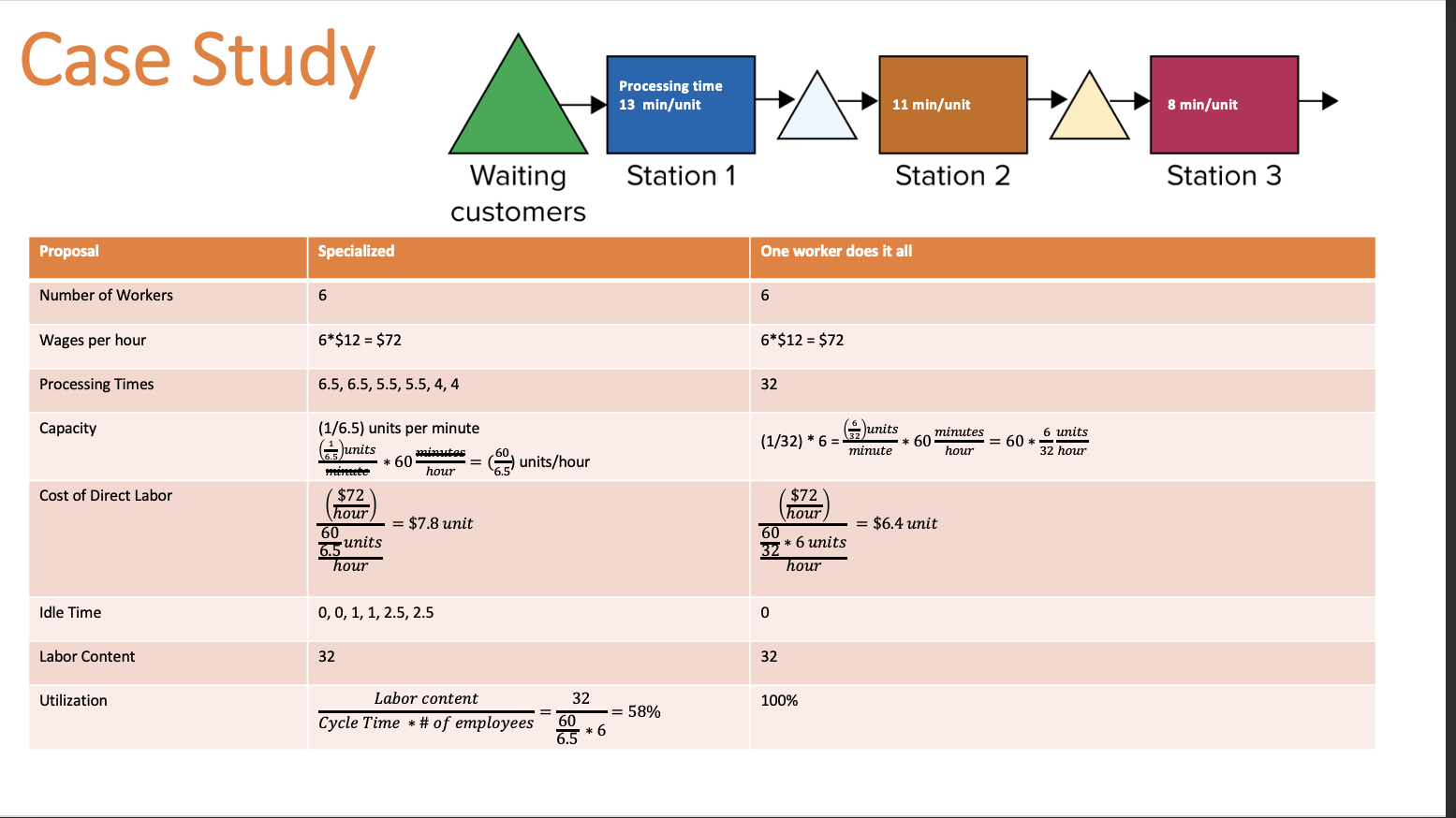

Case Study Components Finished Xootrs Activity 1 Activity 2 Activity 3 Xootr LLC is the producer of a high-end, award-winning kick scooter, known as the Xootr (pronounced "zooter"). The basic Xootr model (known as the Ultra Cruz) sells for slightly over $200. The company started production using a three-step assembly process depicted in the preceding figure. Three workers assemble the Xootr. The processing times are 13 minutes/unit for the first worker, 11 minutes/unit for the second worker, and 8 minutes/unit for the third worker. The assembly operation runs for 35 hours per week. The average salary for an assembly worker is $12 per hour. As demand for the Xootr grows, the company needs to change its assembly operations to increase its process capacity. Two experts are consulted for advice. The first expert comments: "As we grow our business, we really have to benefit from our workers specializing in a small set of activities. Right now, our longest processing time is 13 minutes per unit. If Xootr wants to double its process capacity, it should simply take each of the three activities and break them up into two subactivities. That way, six workers can produce a unit every 6.5 minutes." Another expert, however, disagrees. She observes: Division of labor leads to frustrating, monotone work for the workers. Instead of having workers specialize in small subactivities, Xootr should do the opposite. Imagine one worker would perform all activities from beginning to end. This would avoid the problem of line balancing and increase the labor utilization. And the workers would see how all pieces come together, providing a more meaningful production experience. If we have six workers operating this way, we can have even more capacity." What do you think of the comments of these two experts? Draw a process flow diagram for each of the two expert proposals. For each proposal, compute process capacity, labor utilization, and costs of direct labor, assuming that the processing times in the proposal of the first expert would be cut in half (i.e., it would take 6.5 minutes per unit to do the first set of tasks currently included in activity 1 and another 6.5 minutes per unit to do the second set of tasks). Then, ask yourself what other variables might differ across these two proposals. Case Study Processing time 13 min/unit 11 min/unit 8 min/unit Station 1 Station 2 Station 3 Waiting customers Proposal Specialized One worker does it all Number of Workers 6 6 Wages per hour 6*$12 = $72 6*$12 = $72 Processing Times 6.5, 6.5, 5.5, 5.5, 4,4 32 Capacity Gunits minutes 6 units (1/32) *6 = * 60 = 60* minute hour 32 hour units/hour Cost of Direct Labor (1/6.5) units per minute units minutos *60 mortate hour $72 hour = $7.8 unit 60 6.5 hour $72 hour 60 32 * 6 units hour = $6.4 unit units Idle Time 0, 0, 1, 1, 2.5, 2.5 0 Labor Content 32 32 Utilization 100% Labor content Cycle Time *# of employees 32 = 58% 60 * 6

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts