Question: In Exercise 10.20 provide a 200,000 Btu/hr intercooler on the fourth stage from the top and a 300,000 Btu/h interheater on the fourth stage from

In Exercise 10.20 provide a 200,000 Btu/hr intercooler on the fourth stage from the top and a 300,000 Btu/h interheater on the fourth stage from the bottom.

Data From Problem Exercise 10.20

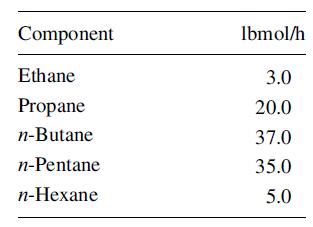

Calculate product compositions, stage temperatures, interstage vapor and liquid flow rates and compositions, reboiler duty, and condenser duty for the following column specifications. Feed (bubble-point liquid at 250 psia and 213.9F):

Column pressure = 250 psia; partial condenser and partial reboiler; Distillate rate = 23.0 lbmol/h; reflux rate = 150.0 lbmol/hr; Number of equilibrium stages (exclusive of condenser and reboiler) = 15;

Feed is sent to middle stage. For this system at 250 psia, K-values and enthalpies may be computed by the Soave–Redlich–Kwong equations.

Component Ethane Propane n-Butane n-Pentane n-Hexane lbmol/h 3.0 20.0 37.0 35.0 5.0

Step by Step Solution

3.52 Rating (162 Votes )

There are 3 Steps involved in it

Solution General Intercooler d... View full answer

Get step-by-step solutions from verified subject matter experts