Question: Tabulated below are reduced test data from measurements made to determine the heat transfer coefficient inside tubes at Reynolds numbers only slightly above transition and

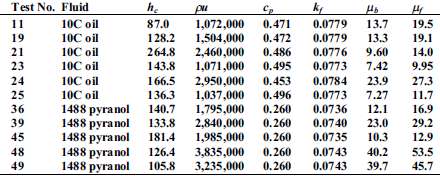

Tabulated below are reduced test data from measurements made to determine the heat transfer coefficient inside tubes at Reynolds numbers only slightly above transition and at relatively high Prandtl numbers (as associated with oils). Tests were made in a double tube exchanger with a counter flow of water to provide the cooling. The pipe used to carry the oils was 5/8-in. OD, 18 BWG, 121 in. long. Correlate the data in terms of appropriate dimensionless parameters.

wherehc = mean surface heat-transfer coefficient based on the mean temperature difference,Btu/(hr sq ft ?F)ρu = mass velocity, lbm/(hr sq ft)cp = specific heat, Btu/(lbm ?F)kf = thermal conductivity, Btu/(hr ft ?F) (based on film temperature)μb = viscosity, based on average bulk (mixed mean) temperature, lbm/(hr ft)μf = viscosity, based on average film temperature, lbm/(hr ft).GIVENOil in a counterflow heat exchangerPipe specifications: 5/8 in. OD, 18 BWGPipe length (L) = 121 in. = 10.08 ftThe experimental data aboveASSUMPTIONSThe data represents the steady state for each caseFrom Appendix 2, Table 42: for 5/8 in. OD, 18 BWG tubing, the inside diameter D = 0.527 in.= 0.0439ft.

h. Test No. Fluid 0.471 0.472 10C oil 87.0 11 1,072,000 1,504,000 0.0779 13.7 19.5 128.2 0.0779 19 10C oil 13.3 19.1 0.0776 14.0 9.95 21 10C oil 264.8 2,460,000 0.486 9.60 10C oil 143.8 1,071,000 7.42 23 0.495 0.0773 24 10C oil 166.5 0.453 23.9 27.3 2,950,000 1,037,000 1,795,000 2,840,000 1,985,000 3,835,000 3,235,000 0.0784 0.496 0.260 0.260 10C oil 136.3 7.27 25 0.0773 11.7 1488 pyranol 1488 l 1488 pyranol 1488 pyranol 1488 pyranol 16.9 36 140.7 0.0736 12.1 29.2 39 133.8 0.0740 23.0 0.0735 45 181.4 0.260 10.3 12.9 126.4 0.0743 40.2 53.5 48 0.260 0.260 0.0743 39.7 49 105.8 45.7

Step by Step Solution

3.35 Rating (158 Votes )

There are 3 Steps involved in it

The appropriate dimensionless parameters are the average Nusselt number Nu h c Dk f The Reynolds num... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

66-E-M-E-H-M-T (1631).docx

120 KBs Word File