Question: Your company is having problems with the Iced stream to a reactor. The feed must be kept at a constant mass flaw rate ( w

Your company is having problems with the Iced stream to a reactor. The feed must be kept at a constant mass flaw rate (w) even though the supply from the upstream process unit varies with time, wi(t). Your boss feels that an available tank can be modified to serve as a surge unit, with the tank level expected to vary up and down somewhat us the supply fluctuates around the desired feed rate. She wants you to consider whether: (1) the available tank should be used, or (2) the tank should be modified by inserting an interior wall, thus effectively providing two tanks in series to smooth the flow fluctuations

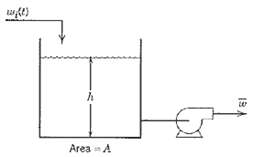

The available tank would be piped as shown in Figure a:

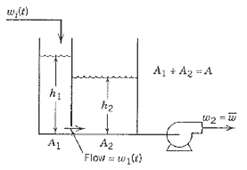

In the second proposed scheme, the process would be modified as shown in figure.

In this case, an opening placed at the bottom of the interior wall permits flow between the two partitions. You may assume that the resistance to flow w1(Q) is constant (= R).

(a) Derive a transfer function model for the two-tank process [H?2(s) |W| (s)] and compare it to the one-tank process (H?(s) |W| (s)j. In particular, for each transfer function indicate its order, presence of any zeros, gain, time constants, presence or absence of an integrating element, whether it is interacting or non-interacting, and so on.

(b) Evaluate how well the two-Lank surge process would work relative to the one-tank process for the case A1 = A2 = A/2 where 4 is the cross-sectional area of the single tank. Your analysis should consider whether h2 will vary more or less rapidly than h for the same input flow rate change, for example, a step input change.

(c) Determine the best way to partition the volume in the two-tank system to smooth inlet flow changes. In other words, should the first tank contain a larger portion of the volume than the second, and so on?

Area A

Step by Step Solution

3.17 Rating (156 Votes )

There are 3 Steps involved in it

a The twotank process is described by the f... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

38-E-C-E-P-C (104).docx

120 KBs Word File