Delayed coking is an oil refinery process that takes a heavy oil fraction and heats it up

Question:

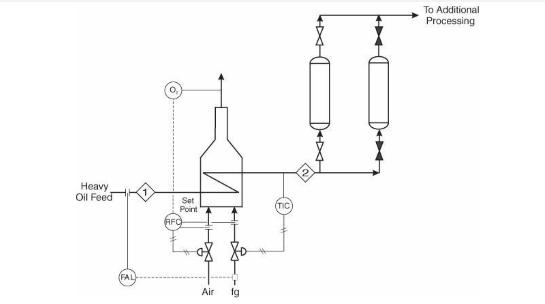

Delayed coking is an oil refinery process that takes a heavy oil fraction and heats it up to approximately \(900^{\circ} \mathrm{F}\left(480^{\circ} \mathrm{C}ight)\) in a furnace. Upon leaving the furnace, the oil is fed to one of two (or more) coking drums, where it is allowed to sit and "cook" for up to 24 hours. During the cooking (coking) process, the oil cracks and gives off a variety of gaseous and liquid products that are processed further. The material remaining in the drums is a solid coke that is subsequently "cut out" of the drum using a very high-pressure water jet. This coke is then shipped out as a salable product. The process is shown in Figure P24.19.

Figure P24.19

The control scheme on the furnace is set to regulate the flow of fuel gas ( \(\mathrm{fg}\) ) based on the measured temperature of the exit oil stream (Stream 2). A ratio flow controller adjusts the flowrate of air so that a constant air/fuel ratio is maintained. An oxygen analyzer measures the excess oxygen in the flue gas and adjusts the set point of the ratio controller to maintain the desired air/fuel ratio. A flow alarm is also present to detect a low flow condition in Stream 1 and activates a solenoid shutoff valve to the fuel gas.

A few days ago there was a process upset in which the oil flow to the fired heater was momentarily interrupted. This interruption triggered the shutoff valve, which closed the fuel gas line. The flow of Stream 1 resumed its normal rate after about 30 seconds, at which time the fuel gas solenoid valve opened and the flow of fuel gas resumed. During the upset, the flow of air changed in proportion to the fuel gas flow.

A short time after this process upset, the following conditions were observed. For each scenario given below, give an explanation of what may have happened to cause the observed changes.

a. The flow of fuel gas to the furnace has slowly increased, and the air flowrate has increased proportionally to maintain the same air/fuel ratio. No other changes have been observed. What could be causing the problem? What do you recommend be done?

b. The flow of fuel gas to the furnace has increased, the air flowrate has increased proportionally to maintain the same air/fuel ratio, and the flow of products and coke production rate appear to be slightly lower than before (the upset). What could be causing the problem? What do you recommend be done?

c. The flow of fuel gas to the furnace has increased, the air flowrate has also increased, and the ratio of air/fuel has increased slightly. The flow of products and coke production rate are lower than before (the upset). What could be causing the problem? What do you recommend be done?

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780132618120

4th Edition

Authors: Richard Turton, Richard C. Bailie, Wallace B. Whiting, Joseph A. Shaeiwitz, Debangsu Bhattacharyya