Question: You are to simulate a single-phase reactor in which a single reaction takes place. The reaction has the general form. In this equation A i

You are to simulate a single-phase reactor in which a single reaction takes place. The reaction has the general form.

In this equation Ai is the ith reactant or product and vi is the stoichiometric coefficient of this species (negative for reactants and positive for products). It is also convenient to define vi for each inert species in the feed to the reactor, assigning it a value of 0. The inputs to the module are the feed stream flow rate, composition, and temperature, the fractional conversion of one of the reactants, and the product stream temperature. The module is to calculate the product stream component flow rates and the required heat transfer to the reactor.

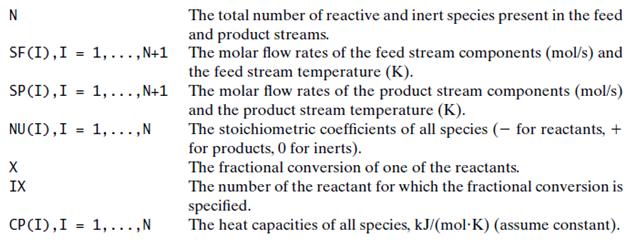

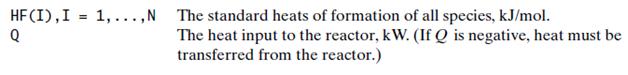

The module equations should be written in terms of the following variables:

Write the equations you would use to calculate and the first components of SP from specified values of all of the other variables defined above.

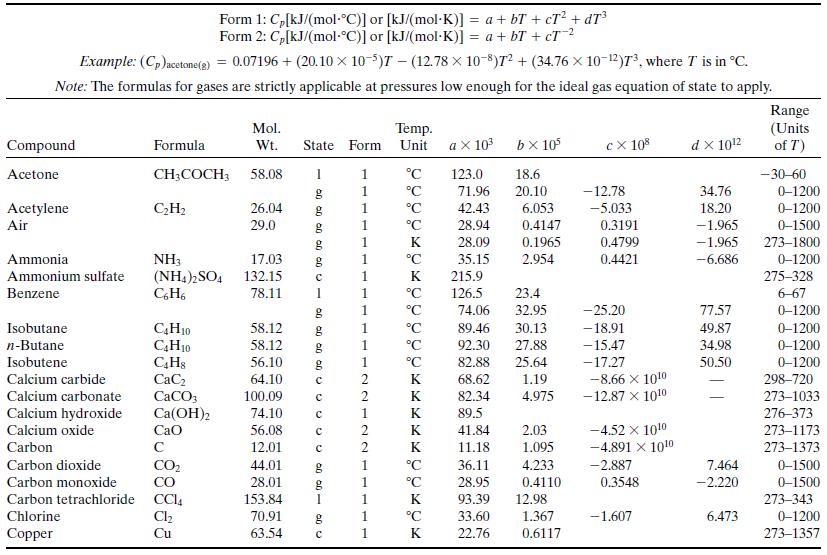

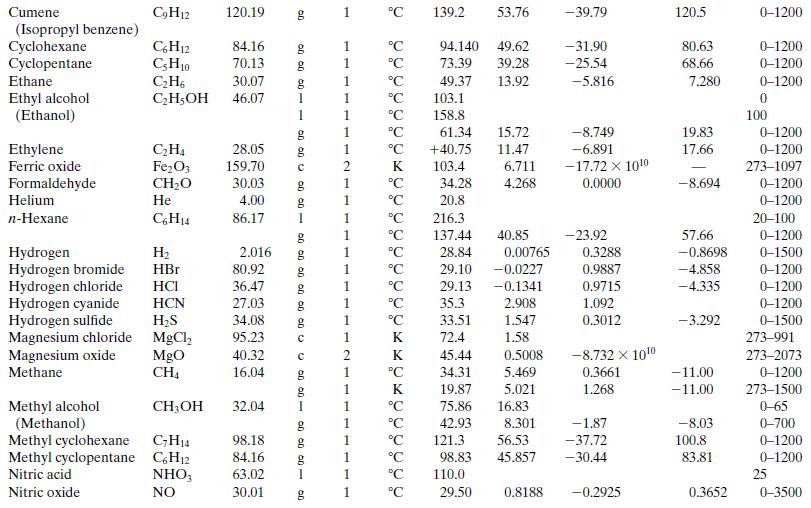

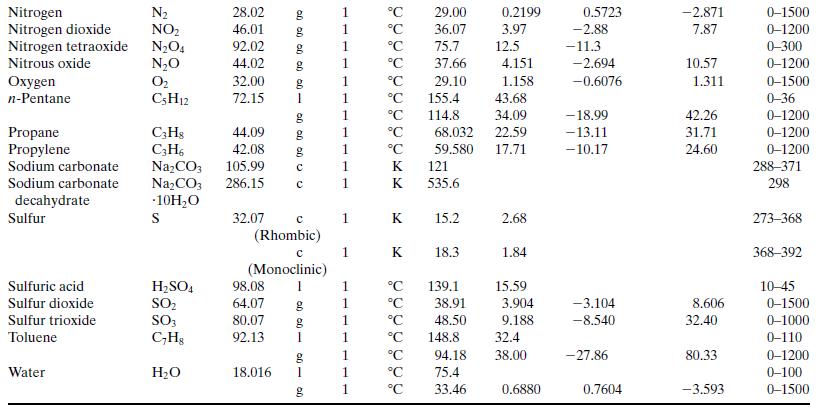

Write a spreadsheet to perform the calculations of part (a) for a reactor in which propane flowing at a rate of 270 standard cubic meters per hour is burned with 20% excess air. The combined stream enters the reactor at 423 K and the stack gas leaves at 1050 K. Ninety percent of the propane fed is converted, and no CO is contained in the stack gas. Take the heat capacity of each species to be its value at 700 K as calculated from Table B.2 [so that, for example, CP(1) = 0.1431 kJ/(mol ∙ K), where (1) refers to propane]. After you have performed the calculations and recorded the output variable values, use the spreadsheet to generate a plot of Q versus stack gas temperature and briefly explain why the plot looks the way it does.

(c) Use an equation-solving program to perform the calculations outlined in part (b).

(d) Write a computer subprogram REACTS to implement the procedure of part (a). The subprogram arguments should be SF, SP, NU, N, X, IX, and Q. The arrays CP and HF should either be transmitted as additional arguments or via a COMMON or GLOBAL statement. Write and run a calling program that defines the input variables, calls the subprogram, and prints out the required out-put variables for the test case of part (b). Number the species involved in the process as follows: 1—C3H8, 2-O2, 3—N2, 4—CO2, 5—H2O. For example, NU(1) = -1, NU(2) = -5, SF(1) = 3.348, SF(3) = 75.54, SF(6) = 423, and SP(6) = 1050. (Verify these values as part of your problem solution.)

Table B.2

The total number of reactive and inert species present in the feed and product streams. SF(I),I = 1,..., N+1 The molar flow rates of the feed stream components (mol/s) and the feed stream temperature (K). SP(I),I = 1,..., N+1 The molar flow rates of the product stream components (mol/s) and the product stream temperature (K). NU(I),I 1,...,N The stoichiometric coefficients of all species (- for reactants, + %3D for products, 0 for inerts). The fractional conversion of one of the reactants. IX The number of the reactant for which the fractional conversion is (I), I specified. The heat capacities of all species, kJ/(molK) (assume constant). 1, ...,N %3D

Step by Step Solution

3.40 Rating (147 Votes )

There are 3 Steps involved in it

To solve the problem of simulating a singlephase reactor with a specified reaction and conditions we need to formulate the equations and create a systematic approach to calculate the product flow rates and heat transfer requirements Heres a structured way to address the problem followed by a sample spreadsheet structure and a computer subprogram outline Part a Define the Equations 1 Stoichiometric Relationships For the reaction of propane CH with air we can represent the combustion reaction as follows C3H8 5O2 376N2 ight arrow 3CO2 4H2O 5 times 376N2 Using stoichiometric coefficients Reactants v1 1 CH v2 5 O v3 188 N Products v4 3 CO v5 4 HO 2 Material Balance The general material balance for the reactor can be described using SPi SFi ui times X times SF1 where X is the fractional conversion of propane SFi are the molar flow rates of the feed components and SPi are the molar flow rates of the products 3 Energy Balance The heat transfer Q to or from the reactor can be computed using the heat capacities CPi Q sumi1N1 SPi times CPi times Tout Tin Where Tin feed stream temperature 423 K Tout product stream temperature 1050 K 4 Initial Inputs and Outputs SF1 textmolar flow rate ... View full answer

Get step-by-step solutions from verified subject matter experts