Beginning in January of 2020, the United States faced an unprecedented health crisis of epic and global

Question:

Beginning in January of 2020, the United States faced an unprecedented health crisis of epic and global proportions. The COVID-19 coronavirus, originating in China, quickly spread around the globe, causing hundreds of thousands of deaths and impacting the lives of millions everywhere. In the United States, one of the country's leading healthcare organizations, Cleveland Clinic, realized that this virus was here for the foreseeable future and would touch every aspect of healthcare delivery. Demand for COVID-19 care very rapidly exceeded the demand for other types of patient services. In addition, Cleveland Clinic had to effectively respond to a historic supply bottleneck where demand for personal protective equipment (PPE) was rapidly increasing between 300% to 1000%, but supply chain production for existing PPE and related supplies could only increase up to 50% of that demand. As Cleveland Clinic supply chain managers readily identified, most of the PPE used in its facilities were sourced off-shore in China, and those supply lines quickly dried up as the pandemic escalated.

Under normal operating conditions, Cleveland Clinic's PPE that came from suppliers and distributors was stored in distribution warehouses after arriving on-shore. This warehouse inventory served as buffers from which the healthcare system could pull needed PPE on a defined schedule based on its historic demand patterns. With the dramatic increase in demand caused by COVID-19, the pull of PPE quickly depleted stored supplies.

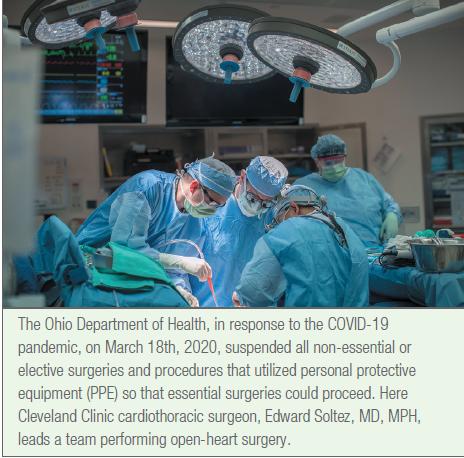

To prepare for the impact of an impending PPE bottleneck on its operations, Cleveland Clinic's facilities across the country flexed and repurposed physical space to accommodate emergency room, intensive care, and general nursing care capacities and staff. Elective surgical procedures and spaces were converted to caring for victims of the COVID-19 virus.

Cross-functional team collaboration between Supply Chain, Philanthropy, Innovations, Surgical Operations, Quality and Patient Safety, and the Clinical Institutes took top priority in addressing the looming constraints. These departments rapidly devised a new holistic supply response team that approached the challenges of the pandemic from six distinct work stream strategies: • BUY as much PPE as the available market offered

• MAKE PPE components that could not be sourced from suppliers

• SEEK DONATIONS to help the hospital offset the increased cost of sourcing outside normal contracts

• DISINFECT and reuse some PPE items to recycle into workflows

• MANAGE USE of PPE to minimize waste and assure supplies were properly deployed

• MONITOR DATA ANALYTICS to get a better sense of what was occurring in the PPE management process The shift towards caring for infected COVID-19 patients meant the organization needed to quickly assess its supply chain to determine where bottlenecks existed in procuring ventilator equipment and personal protective equipment (PPE) such as respirator face masks, isolation gowns, gloves, hand sanitizer, and other materials essential to the safety of each and every patient and healthcare worker. Cleveland Clinic's Objectives and Key Results (OKRs) are centered around patient safety, highest-quality patient care, and delivery of an optimal patient experience. Everyone knew that understanding and addressing these immediate needs became paramount, and that having the right PPE in the right places at the right time was needed.

From the theory of constraints perspective as shown in Table 6.2, Cleveland Clinic shifted its focus to the following principles:

1. Balancing flow of resources--material, people, and physical space to accommodate increased demand

2. Recognizing that the sudden shift to managing the throughput of a completely new care protocol might mean loss of efficiency in the short run

3. Identifying where bottlenecks would cause a loss of efficiency, such as in the inability to procure PPE in a timely manner

4. Front-loading PPE and other required materials in anticipation of a spike in demand in the coming weeks and months

5. Assuring both upstream and downstream personnel, processes, and materials were realigned to enhance the flow of work in the system to avoid future bottlenecks and unnecessary inventory build-up and operating expense

6. Redirecting non-bottleneck resources from other clinical activities and non-emergency services to address constraints in impacted areas of operations

7. Tracking capital investments in new equipment and flexed facilities to be sure that the overall impact of these measures did not negatively affect patient care and safety outcomes, materials inventories, and operating expense.

Realizing that the task of global sourcing was beyond the scope of supply chain procurement alone, clinic staff in Philanthropy, Innovations, and Surgical Operations joined forces for an integrated team approach to managing the crisis. Every healthcare provider around the globe was clamoring for the same finite set of PPE resources, which meant there would not be enough supply to meet worldwide demand. The Chief Executive Officer and President of Cleveland Clinic, Dr. Tom Mihaljevic's motto of "A team of teams" was visible everywhere in the health system. This approach allowed people at every level to contribute ideas on how to improve processes and procedures and

create a climate of teamwork and shared responsibility to work around the PPE bottleneck.

QUESTIONS

1. Consider the six work stream strategies that Cleveland Clinic activated to meet the sudden increase in demand for its services. Going forward, which of those strategies is most sustainable? Why?

2. In which way did Cleveland Clinic achieve a global optimum in managing its COVID-19 constraints instead of just focusing on local solutions? Could it have been equally effective without such a holistic approach?

3. What future bottlenecks might Cleveland Clinic avoid by continuing to monitor its PPE activity through its data analytics and dashboard reporting systems?

Step by Step Answer:

Operations Management Processes And Supply Chains

ISBN: 9781292409863

13th Global Edition

Authors: Lee Krajewski, Naresh Malhotra, Larry Ritzman