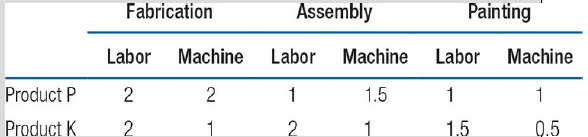

The manufacturing sequence for two products that a company produces involves fabrication, assembly, and painting operations. Each

Question:

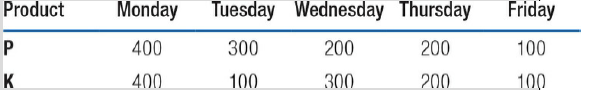

The available labor and machine capacities at each department are 800 hours of labor and 600 hours for each day of a 5-day work week. For the upcoming work week, the company has developed the following production schedule for the two products.

Assuming no setup or change-over time, determine the capacity requirements for each product and the total load for each of the three departments for each day of the 5-day work week.

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Operations Management Managing Global Supply Chains

ISBN: 978-1506302935

1st edition

Authors: Ray R. Venkataraman, Jeffrey K. Pinto

Question Posted: