Question: . . . . 258 Unitron Corporation EXHIBIT 1 The Chip Step 1 Glass... 256 T Tt Unitron Corporation This case is set in 1974

. . . . 258 Unitron Corporation EXHIBIT 1 The Chip Step 1 Glass...

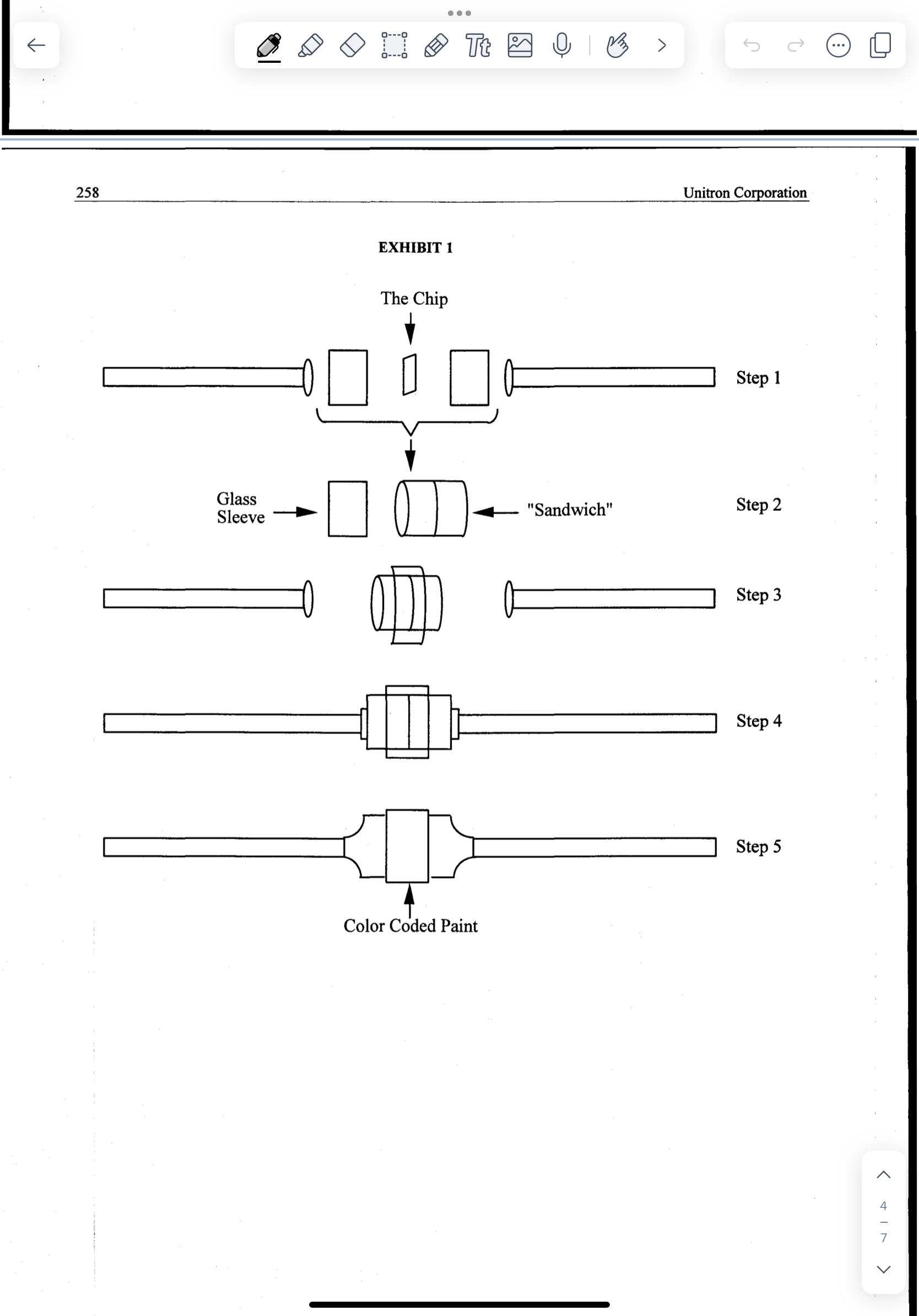

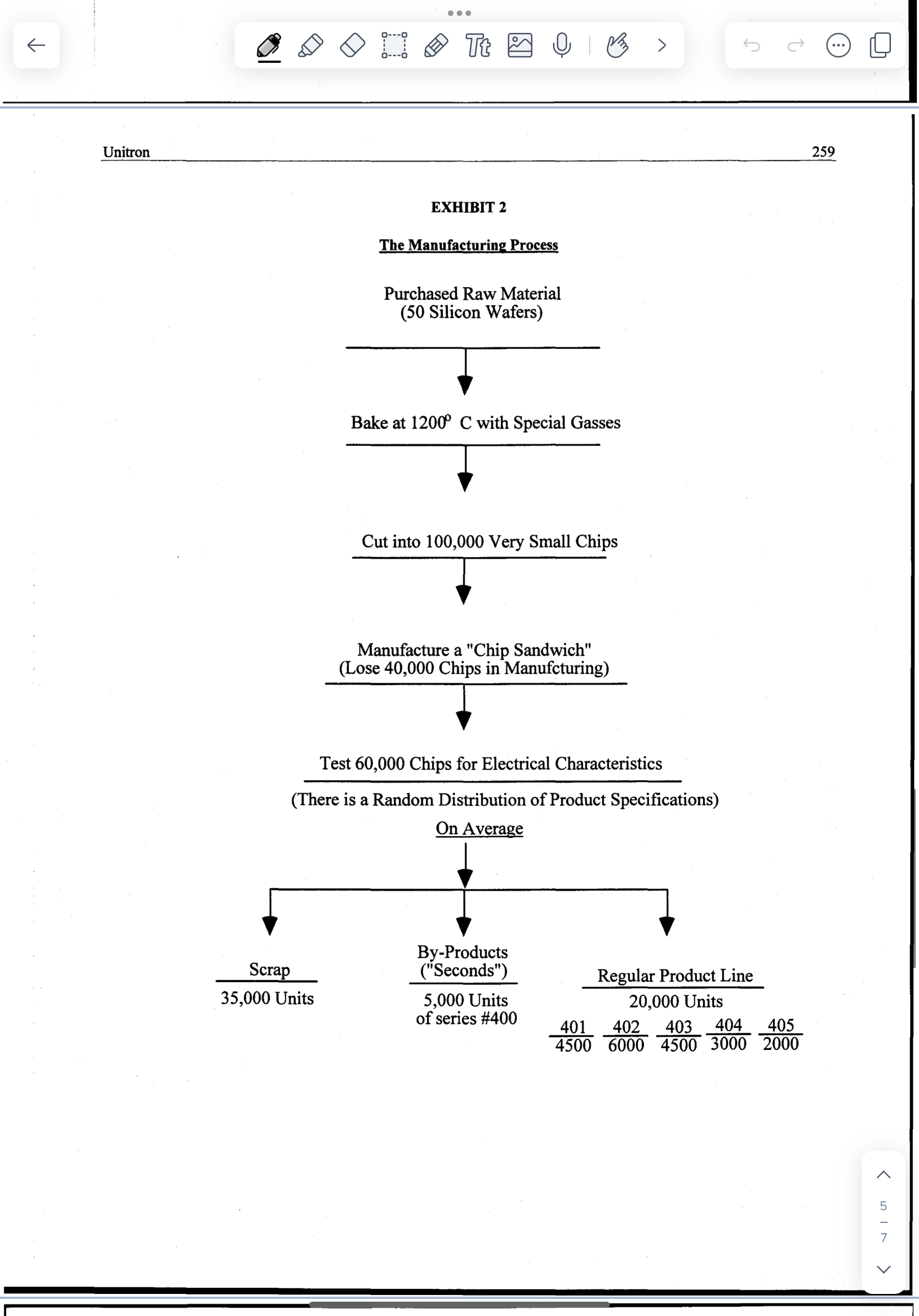

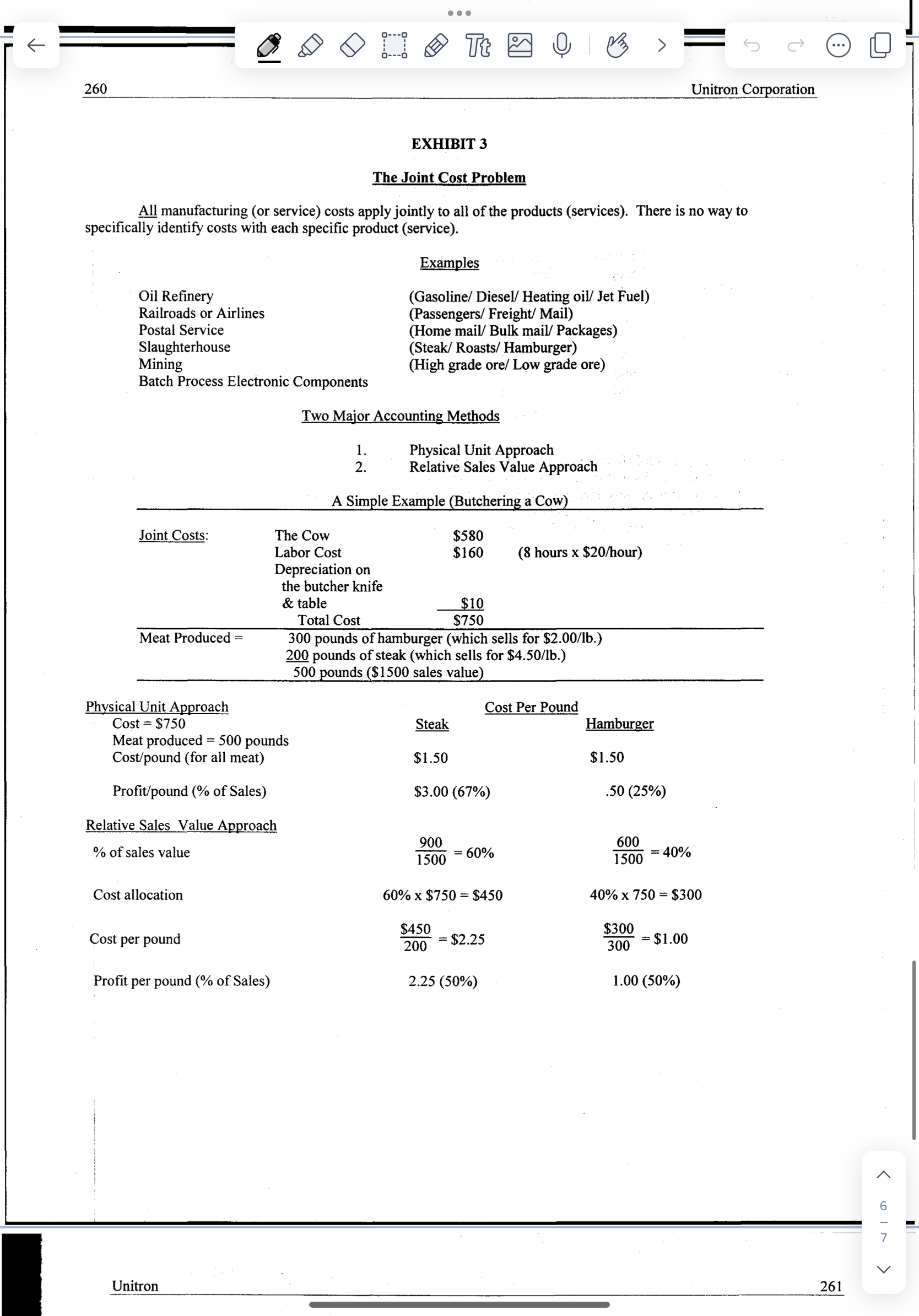

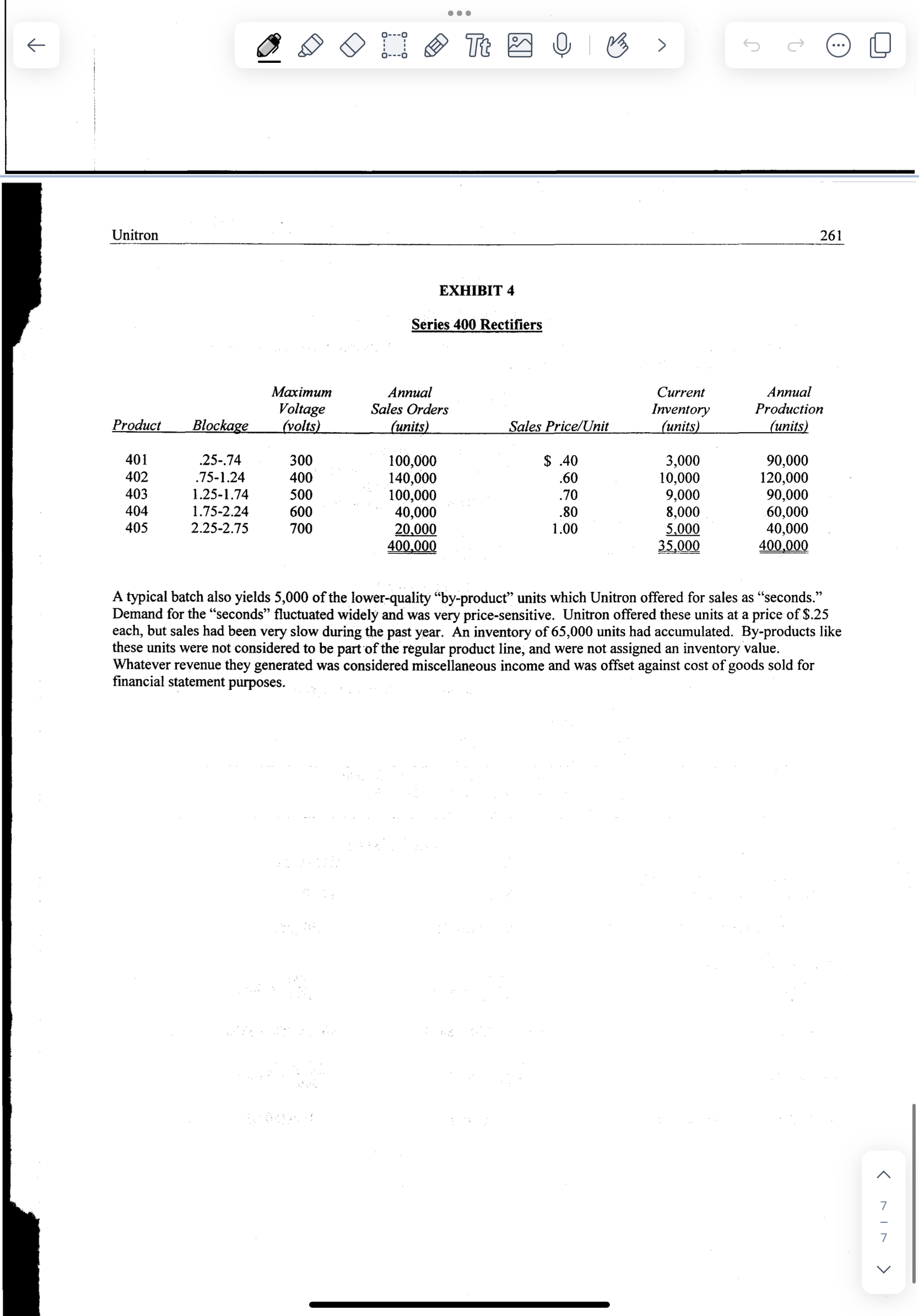

256 T Tt Unitron Corporation This case is set in 1974 in a Boston-based "hi-tech" firm which was a pioneer in the "solid state" electronic components that were the basis for third generation" computers and were the early prototypes for modern integrated circuits. The basic issue is the classic "joint cost dilemma. In 1974, Unitron Corporation was only 20 years old, but it had already succeeded in positioning itself as a respected producer of high-quality electronic components. Included among the firm's product lines were rectifiers, thyristors, zeners, diodes, and other high-voltage assemblies. These products represent fundamental electronic components in such fields as minicomputers, process controllers, defense systems, and communications equipment. With sales of $30 million, Unitron was clearly much smaller than the component industry's "Big Three" of Texas Instruments, Fairchild, and Motorola. However, by concentrating on high performance in selected high-quality segments of the market, Unitron had developed into the market leader in many specialty components. This gave the firm a competitive advantage that permitted them to maintain a price-leadership position within these segments. Rectifiers were a significant product group for Unitron. A rectifier's function is to allow electrical current to pass in one direction while preventing movement in the reverse direction. Its action therefore is similar to that of a valve in fluid mechanics. Exhibit 1 shows the steps in producing a completed rectifier unit which is about 1/2 the size of a cigarette. The value of this product to the final user is primarily determined by two characteristics; the rapidity of response in blocking current reversals and the "surge capacity" or maximum voltage level the rectifier can withstand. Unfortunately, for all manufacturers including Unitron, there is no known method of controlling production procedures to obtain exact electrical characteristics. Each production batch differs from other batches processed under ostensibly the same conditions. Furthermore, within each batch, the individual units do not have precisely the same characteristics. Over many production runs, the distribution of unit characteristics closely resembles a standard "bell curve." The production process starts by placing a batch of 50 silicon wafers (purchased from outside suppliers) in a furnace heated to 1,200C and containing specially prepared metallic gas impurities. By altering the concentration of the impurities, different electrical characteristics can be induced in the wafers. However, an improvement in one characteristic is often accompanied by a decline in another. Also, in spite of strict monitoring of the furnace conditions, small differences in temperature and gas distribution do occur and these variations alter the final products. Upon leaving the furnace, each wafer is cut into about 2,000 silicon chips, each approximately the size of a ball-point pen tip. Exhibit 1 illustrates the production sequence then followed. First a chip is fused between two metal cylinders making a "sandwich." In Step 2 this "chip sandwich" is enveloped in a glass sleeve. In Step 3 this sleeve is heated while in place, forming a molecular bond with the silicon chip. Silver or copper wires are then attached in Step 4. In Step 5, the finished product is painted according to a color code. The wafers and chips are tested at each step during production for physical and electrical defects. About 60% of the 100,000 chips in a batch reach the end of Step 3. Of that percentage, only one-third or less are eventually sold as part of the regular product line. Another 5,000 units at the lower end of the distribution have limited marketability and are not repairable. Although Unitron did not consider these items to be part of the regular product line, they were offered for sale as "seconds" for use as components in relatively inexpensive and usually disposable items such as toys or small home appliances. No marketing effort was devoted to these by-product units. manufacturing process in summarized in Exhibit 2. The overall Unitron Corporation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts