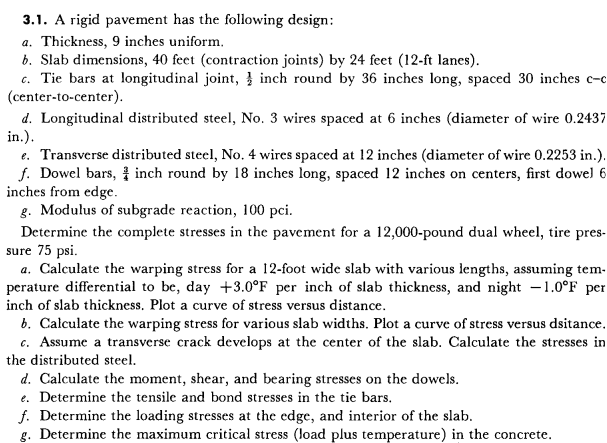

Question: 3 . 1 . A rigid pavement has the following design: a . Thickness, 9 inches uniform. b . Slab dimensions, 4 0 feet (

A rigid pavement has the following design:

a Thickness, inches uniform.

b Slab dimensions, feet contraction joints by feet ft lanes

c Tie bars at longitudinal joint, inch round by inches long, spaced inches

centertocenter

d Longitudinal distributed steel, No wires spaced at inches diameter of wire

in

e Transverse distributed steel, No wires spaced at inches diameter of wire

Dowel bars, inch round by inches long, spaced inches on centers, first dowel

inches from edge.

g Modulus of subgrade reaction, pci.

Determine the complete stresses in the pavement for a pound dual wheel, tire pres

sure

a Calculate the warping stress for a foot wide slab with various lengths, assuming tem

perature differential to be day per inch of slab thickness, and night per

inch of slab thickness. Plot a curve of stress versus distance.

Calculate the warping stress for various slab widths. Plot a curve of stress versus dsitance.

c Assume a transverse crack develops at the center of the slab. Calculate the stresses in

the distributed steel.

d Calculate the moment, shear, and bearing stresses on the dowels.

e Determine the tensile and bond stresses in the tie bars.

Determine the loading stresses at the edge, and interior of the slab.

g Determine the maximum critical stress load plus temperature in the concrete.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock