Question: 3, common technique that's used when a project gets behind schedule? a crashing b. forward planning c. pull systems d. retro- scheduling 4. Generally part

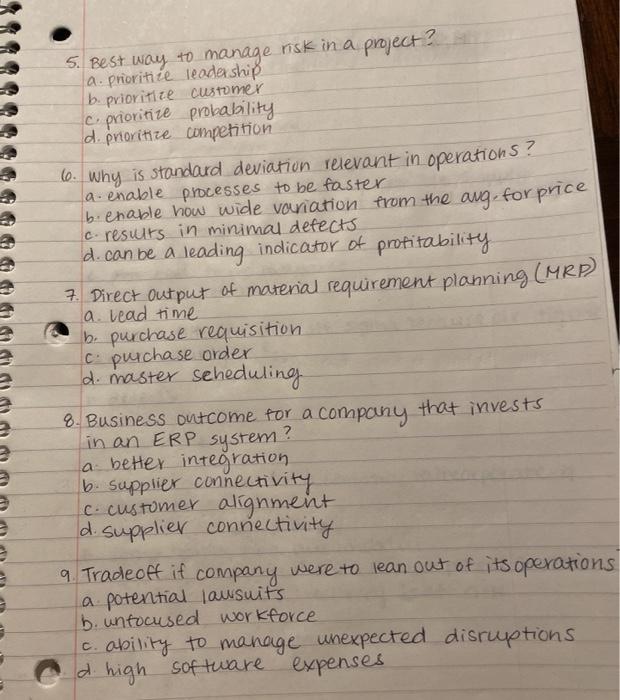

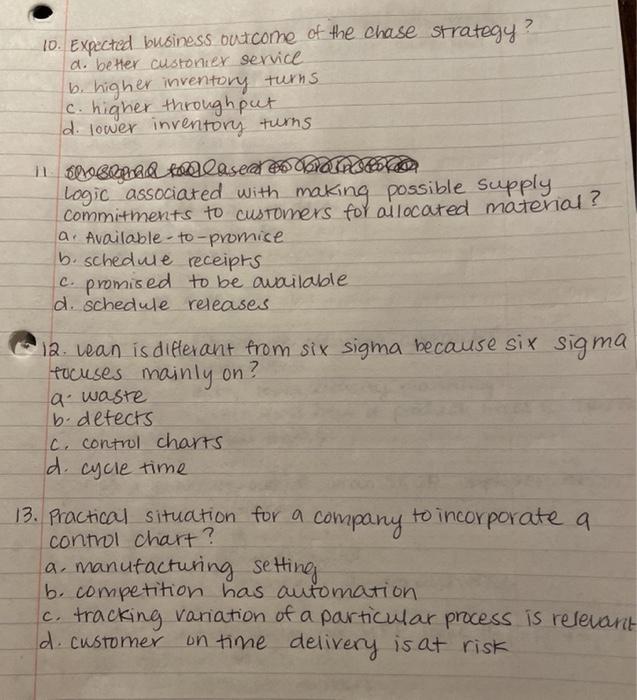

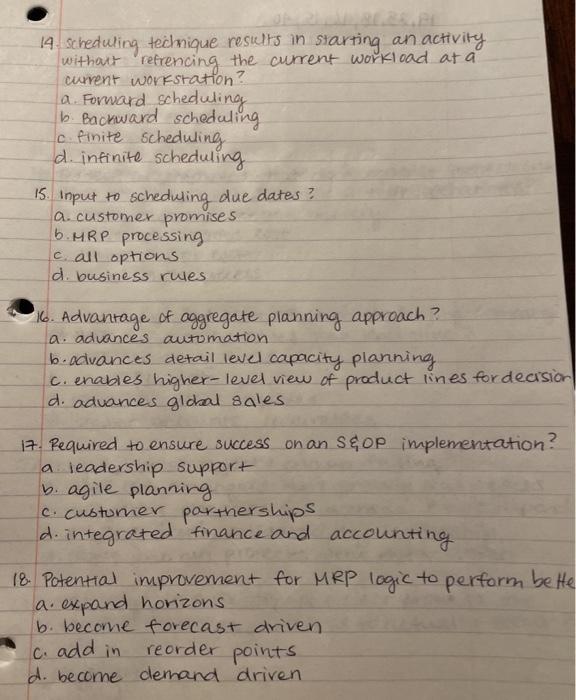

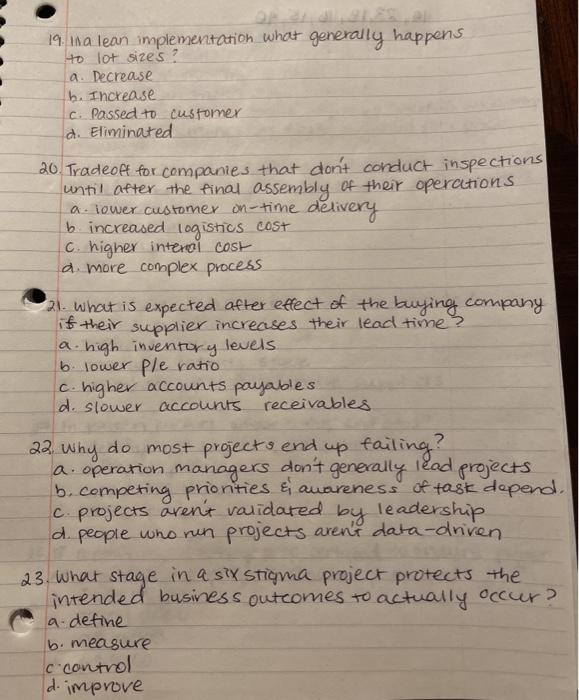

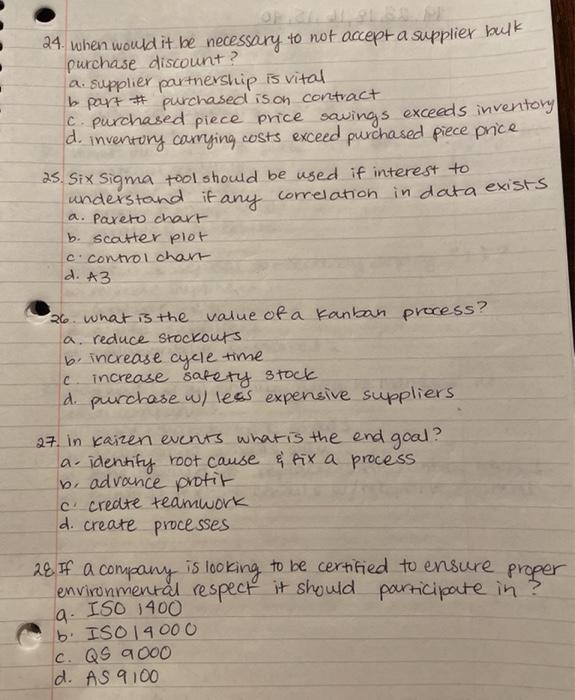

3, common technique that's used when a project gets behind schedule? a crashing b. forward planning c. pull systems d. retro- scheduling 4. Generally part of the critical path if a project scope is to transter a production line a. Transterring Inventory b. moving equipment c. training employees d. informing departments G 5. Best way to manage risk in a project? a prioritie leadership b. prioritize customer c, prioritize probability d prioritize competition 60. Why is standard deviation relevant in operations? a. enable processes to be faster b:enable now wide variation from the aug. for price C-results in minimal detects d. can be a leading indicator of profitability 7. Direct output of material requirement planning (MRD a. lead time be purchase requisition c purchase order di master seheduling 8. Business outcome for a company that invests in an ERP system? a better integration b. supplier connectivity c. customer alignment d. supplier connectivity 9. Tradeoff if company were to lean out of its operations a potential lawsuits b. unfocused workforce cability to manage unexpected disruptions d high software expenses ? 10. Expected business outcome of the chase Strategy a. better custoniex service b. higher inventory turns higher throughput d. lower inventory turns. i sobre telased ea border Logic associated with making possible supply commitments to customers for allocated material? a. Available-to-promice b. schedule receipts. c. promised to be available d. schedule releases 12. vean is difterant from six sigma because six sigma focuses mainly on? a waste b. defects c. control charts d. cycle time 13. Practical situation for a company to incorporate a control chart? a manufacturing setting b. competition has automation c. tracking variation of a particular process is relevant d. customer on time delivery is at risk tion 14 scheduling technique results in starting an activity without retrencing the current workload at a current workstation? a. Forward scheduling b. Backward scheduling lo finite scheduling d. infinite scheduling 15. Input to scheduling due dates ? a customer promises b.HRP processing c. all options di business rules 16. Advanrage of aggregate planning approach? a. advances automation b.advances detail level capacity planning c. enables higher-level view of product lines for deasion di oduances glcral sales 17. Pequired to ensure success on an scop implementation? a leadership support b. agile planning c. customer partherships d. integrated finance and accounting 18 Potential improvement for MRP logic to perform bette a expand horizons b. become forecast driven c. add in do become demand driven reorder points 19.100 lean implementation what generally happens to lot sizes? 9. Decrease b. Increase c. Passed to customer d. Eliminated 20 Tradeoft for companies that don't conduct inspections until after the final assembly of their operations a lower customer on-time delivery b increased logistics cost c higher interoi COSE d more complex process a. 21. what is expected after effect of the buying company if their supplier increases their lead time high inventory levels blower ple ratio higher accounts payables d. slower accounts receivables 22 why do most projects end up failing? a. operation managers don't generally projects b. competing priorities & auareness of task depend c. projects aren't validated by leadership d. people who run projects aren't data-driven 23. what stage in a six stigma project protects the intended business outcomes to actually occur? a define b. measure c control do improve d. 24. when would it be necessary to not accepta supplier bulk purchase discount? a. supplier partnership is vital b purt # purchased is on contract c. purchased piece price savings exceeds inventory inventory carrying costs exceed purchased piece price 25. Six Sigma tool should be used if interest to understand it any correlation in data exists a. Pareto chart b. scatter plot c control chart d. A3 26. what is the value of a kanban process? a reduce Stockouts b. increase cycle time. increase safety stock d. purchase w/ leas expensive suppliers 27. in kaizen events what is the end goal? a identity root cause & fix a process b. advance protit c create teamwork d. create processes 28. If a company is looking to be certified to ensure proper environmental respect it should participate in ? a a. ISO 1400 b. ISO 14000 C. QS aooo d. AS 9100 1. Six Sigma tool thats used to brainstorm w/ team to find causes & effects driven by various inputs a.control chart b. project charter c. Pareto chart d. fishbone diagram 2. If the average demand for a item is 100 units per day, lead time is 4 days, and safety stock is 100 units, the the reorder point is ? la 60o [b. 400 C 550 ld, soo

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts