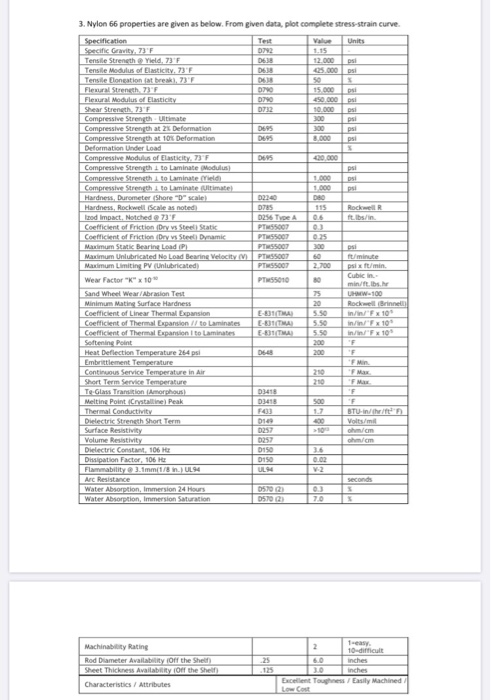

Question: 3. Nylon 66 properties are given as below. From given data, plot complete stress-strain curve. Value Units 1.15 Specification Specific Gravity, 73F Tensile Strength

3. Nylon 66 properties are given as below. From given data, plot complete stress-strain curve. Value Units 1.15 Specification Specific Gravity, 73F Tensile Strength @ Yield, 73 F Tensile Modulus of Elasticity, 73'F Tensile Elongation (at break), 73 F Flexural Strength, 73 F Flexural Modulus of Elasticity Shear Strength, 73 F Compressive Strength Ultimate Compressive Strength at 2% Deformation Compressive Strength at 10% Deformation Deformation Under Load Compressive Modulus of Elasticity, 73 F Compressive Strength 1 to Laminate (Modulus) Compressive Strength to Laminate (Yield) Compressive Strength to Laminate (Ultimate) Hardness, Durometer (Shore "D" scale) Hardness, Rockwell (Scale as noted) Izod Impact, Notched @ 73 F Coefficient of Friction (Dry vs Steel) Static PTM55007 Coefficient of Friction (Dry vs Steel) Dynamic PTM55007 Maximum Static Bearing Load (P) PTM55007 Maximum Unlubricated No Load Bearing Velocity (V) PTM55007 Maximum Limiting PV (Unlubricated) PTM55007 Wear Factor "K" x 10 PTM55010 Sand Wheel Wear/Abrasion Test Minimum Mating Surface Hardness Coefficient of Linear Thermal Expansion Coefficient of Thermal Expansion // to Laminates Coefficient of Thermal Expansion I to Laminates Softening Point Heat Deflection Temperature 264 pi Embrittlement Temperature Continuous Service Temperature in Air Short Term Service Temperature Te-Glass Transition (Amorphous) Melting Point (Crystalline) Peak Thermal Conductivity Dielectric Strength Short Term Surface Resistivity Volume Resistivity Dielectric Constant, 106 H Dissipation Factor, 106 Hr Flammability @ 3.1mm(1/8 in.) UL94 Arc Resistance Water Absorption, Immersion 24 Hours Water Absorption, Immersion Saturation Test 0792 0638 D638 0638 0790 0790 0732 Machinability Rating Rod Diameter Availability (Off the Shelf) Sheet Thickness Availability (Off the Shelf) Characteristics/ Attributes D695 0695 0695 02240 0785 0256 Type A E-831(TMA) E-831(TMA) E-831TMA D3418 D3418 F433 0149 0257 0257 D150 0150 UL94 0570 (2) 0570 (2) 25 125 12.000 425.000 15.000 450,000 10,000 300 300 8,000 420,000 1,000 1,000 D60 115 0.6 0.3 0.25 60 2,700 FR55588 22 8285 295 32 5.50 >10 0.02 2 6.0 3.0 psi psi S psi psi psi psi psi psi psi psi psi Rockwell R ft.ibs/in ft/minute psix ft/min. Cubic in min/ft.ibs.hr UHMW-100 Rockwell (Brinnell) in/in/"Fx 10 in/in/F x 10 in/in/Fx 10 "F 'F 'F Min Max F Max 'F "F BTU-in/(hr/ftF) Volts/mil ohm/cm ohm/cm seconds S S 1-easy. 10-difficult inches inches Excellent Toughness / Easily Machined/ Low Cost

Step by Step Solution

3.32 Rating (152 Votes )

There are 3 Steps involved in it

Using the properties moisture content etc the stress psi strain curve of the nylon ... View full answer

Get step-by-step solutions from verified subject matter experts