Question: 3.1- You want to implement SPC in your manufacturing processes to ensure that the products will leave the factory with no defects. According to the

3.1- You want to implement SPC in your manufacturing processes to ensure that the products will leave the factory with no defects. According to the attached process which steps are more critical to quality? Which information do you need to ensure the capability of your processes? Which processes do you need to control and which metrics would you measure? Which type of charts do you need to do to ensure the stability of your processes?

DATA WRITTEN:

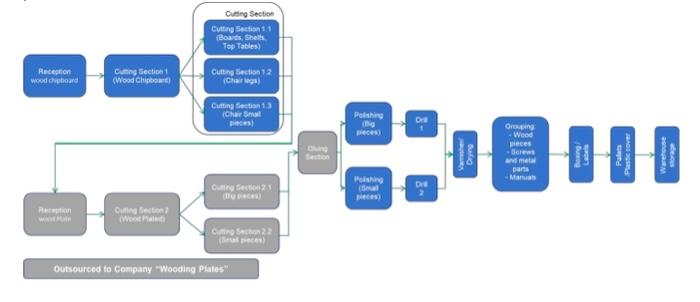

Reception wood chipboard-> Cutting Section 1

(Wood Chipboard)-> Cutting Section

Cutting Section 1.1 (Boards, Shelfs, Top Tables)

Reception wood chipboard

Cutting Section 1 (Wood Chipboard)

Cuttina Section 1.2 (Chair leas)

Cutting Section 1.3 (Chair Small pieces)

then this cutting section goes -> Reception wood Plate -> Cutting Section 2 (Wood Plated)

Cutting Section 2.1 (Big pieces)

Cutting Section 2.2

(Small pieces)

then Gluing Section -> pulishing -> drill -> Varnisher/ Drying -> grouping wood piece, screws and metal parts, manuals -> boxing/labels -> pallets/plastic cover -> warehouse storage

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts