Question: A= 5, B=7, C=5, D=8, E=700 Write a linear programming model for the following problem. ATK- Beyaz manufactures two mechanical parts in its factory in

A= 5, B=7, C=5, D=8, E=700

Write a linear programming model for the following problem. ATK-Beyaz manufactures two mechanical parts in its factory in Istanbul. The first part is produced by processing 2 units of sheet metal and A unit of profile pipe. For the second part, 3 units of sheet metal and 1 unit of profile pipe are required. The company has 1000 units of sheet metal and 1200 units of profile pipes, and if necessary, sheet metal at a price of 100 TL/unit and profile pipe can be supplied at a price of (B*10) TL/unit. Parts are processed on CNC or conventional machines. The company has 2 CNC and C conventional workbenches. Table 1 shows the number of parts that can be produced in one shift if a machine is completely separated into that part.

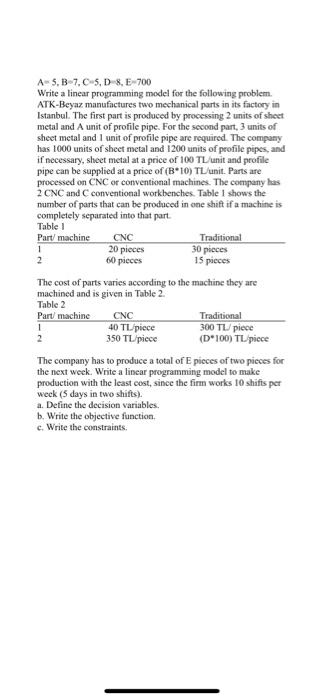

Table 1

Part/ machine CNC Traditional

1 20 pieces 30 pieces

2 60 pieces 15 pieces

The cost of parts varies according to the machine they are machined and is given in Table 2.

Table 2

Part/ machine CNC Traditional

1 40 TL/piece 300 TL/ piece

2 350 TL/piece (D*100) TL/piece

The company has to produce a total of E pieces of two pieces for the next week. Write a linear programming model to make production with the least cost, since the firm works 10 shifts per week (5 days in two shifts).

a. Define the decision variables.

b. Write the objective function.

c. Write the constraints.

A=5,B=7,C=5,D=8,E=700 Write a lincar programming model for the following problem. ATK-Beyaz manufactures two mechanical parts in its factory in Istanbul. The first part is produced by processing 2 units of sheet metal and A unit of profile pipe. For the second part, 3 units of sheet metal and 1 unit of profile pipe are required. The company has 1000 units of sheet metal and 1200 units of pronile pipes, and if necessary, sheet metal at a price of 100 TL/unit and profile pipe can be supplied at a price of (B10) TLunit. Parts are processed on CNC or conventional machines. The company has 2CNC and C conventional workbenches. Table 1 shows the number of parts that can be produced in one shift if a machine is completely separated into that part Tahio I The cost of parts varies according to the machine they are machined and is given in Table 2 Tahle 2 The company has to produce a total of E pieces of two pieces for the next week. Write a linear programming model to make production with the least cost, since the firm works 10 shifis per week ( 5 days in two shifts). a. Detine the decision variables. b. Write the objective function. c. Write the constraints

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts