Question: A manager is trying to decide whether to purchase a certain part or to have it produced intomally. Internal production could use other of two

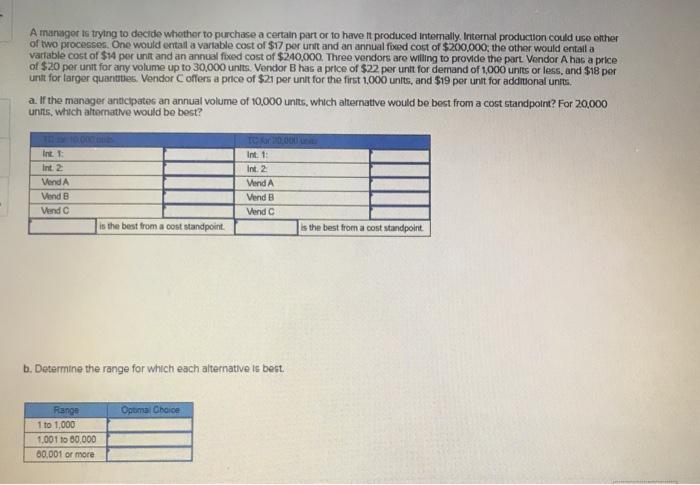

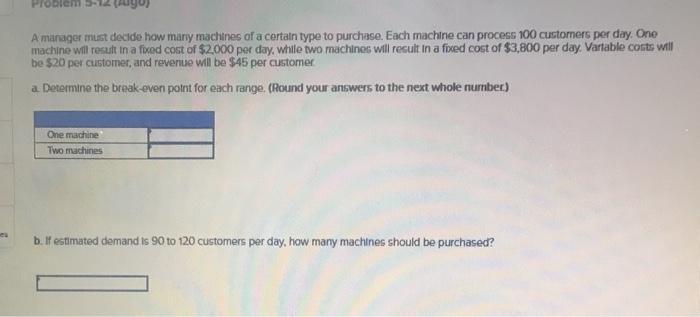

A manager is trying to decide whether to purchase a certain part or to have it produced intomally. Internal production could use other of two process. One would entalla variable cost of $17 per unit and an annual fixed cost of $200,000; the other would entalla vartable cost of $14 per unit and an annual fixed cost of $240,000. Three vendors are willing to provide the part. Vendor A has a price of $20 per unit for any volume up to 30,000 units. Vendor B has a price of $22 per unit for demand of 1,000 units or less, and $18 per unit for larger quantities. Vendor C offers a price of $21 per unit for the first 1,000 units, and $19 per unit for additional units. a. If the manager anticipates an annual volume of 10,000 units, which alternative would be best from a cost standpoint? For 20,000 units, which alternative would be best? Int Int2 Vend A Vend B Vend Int: 1 Int. 2 Vend A Vend B Vend is the best from a cost standpoint is the best from a cost standpoint b. Determine the range for which each alternative is best Optima Choice Fange 1 to 1,000 1,001 to 80,000 80,001 or more tay" A manager must decide how many machines of a certain type to purchase. Each machine can process 100 customers per day. One machine will result in a fixed cost of $2.000 per day, while two machines will result in a fixed cost of $3,800 per day. Variable costs will be $20 per customer, and revenue will be $45 per customer a Determine the break-even point for each range. (Round your answers to the next whole number) One machine Two machines b. If estimated demand is 90 to 120 customers per day, how many machines should be purchased