Question: A mining plant is currently having maintainability problems. Its process is made up of 3 areas: primary crushing, conveyor belt, and secondary crushing. This process

A mining plant is currently having maintainability problems. Its process is made up of 3 areas: primary crushing, conveyor belt, and secondary crushing. This process was designed to work at 5 tons/hour. The plant works 720 hours per month, with a production capacity of 3,600 tons per month at a price of 100 um/month (um = monetary unit), while the goal is 20,000 tons per year.

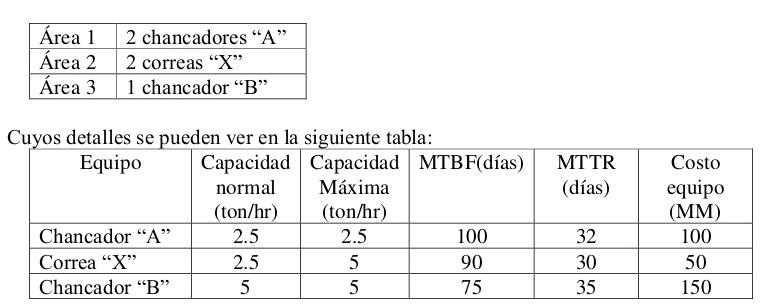

Each area has the following equipment:

Due to process conditions, the crusher can only operate at 5 tons per hour, operating costs are 1 MM per year per team and variable costs correspond to 30% of the price. The evaluation horizon is 10 years with a discount rate of 15%.

a) Determine if the goal for the year (production) and global costs can be met.

b) How much would you be willing to pay to have a new crusher "A" in area 1, so the same characteristics as those already owned (assume the costs of operation do not change)?

c) What would be the availability in case of having a new reserve "B" crusher,with the same characteristics as the current one? (do not consider what was done in question b) Help: - Consider functional and logical diagram.

- Consider the effects of availability/unavailability.

Cuyos detalles se pueden ver en la siguiente tabla

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts