Question: A small manufacturing system processes two high volume parts: P 1 and P 2 . Each of 50 units of P 1 is first processed

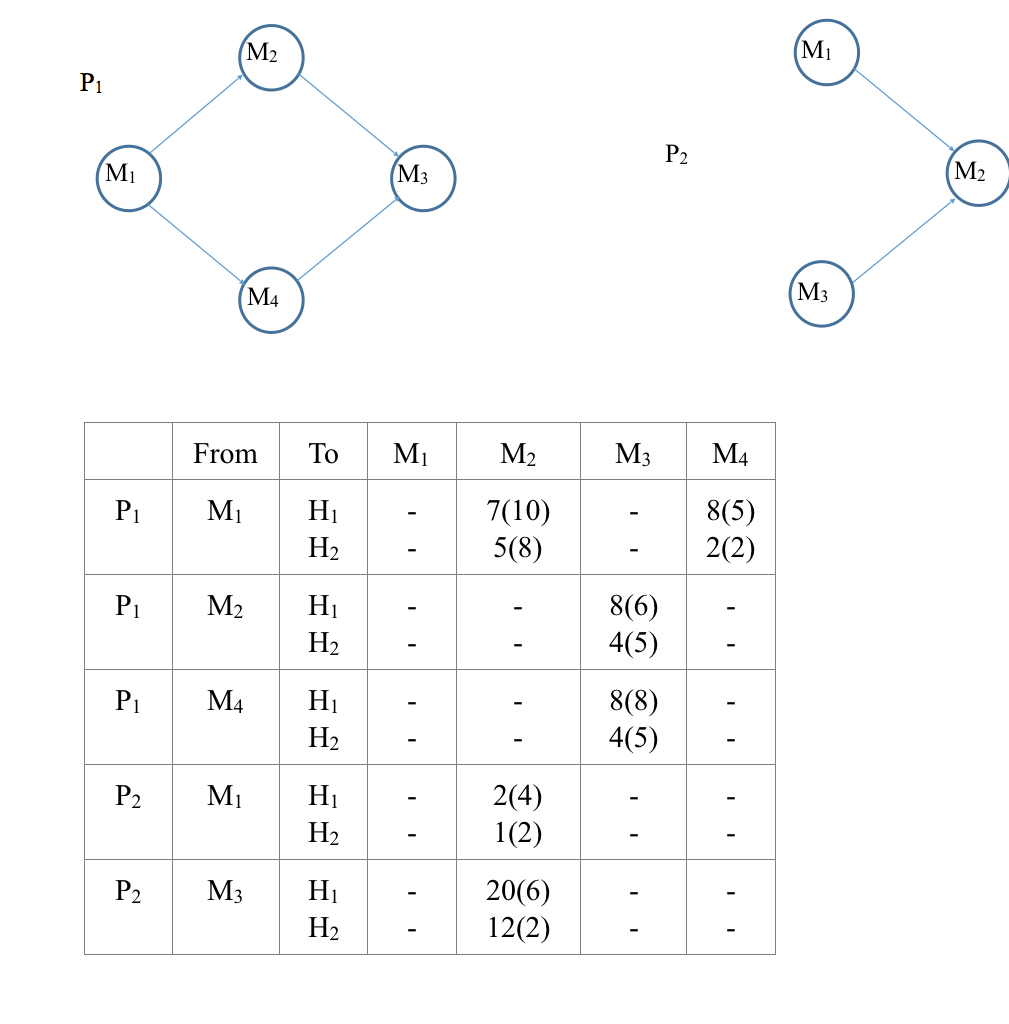

A small manufacturing system processes two high volume parts: P1 and P2. Each of 50 units of P1 is first processed on M1 and then sent to machine M2 or M4, where it is further processed and then sent to M3 for final processing. In addition to P1, the manufacturing facility processes 60 units of P2, of which 30 are processed first on M1, and then machine M2. Because machine M3 can do the same processing as machine M1 for part P2, the remaining 30 units of part P2 are processed first on machine M3 and then sent to machine M2 for final processing. Two candidate Material Handling Systems, H1 and H2 with purchase costs 100,000 TL and 140,000 TL respectively, are being considered. The unit cost of transporting P1 and P2 on each of the MHSs between the machines are given in the following table. The corresponding transportation times per unit (in minutes) are provided in parentheses in the table. Assume that there are 7150 minutes in the planning period and each handling device is expected to make empty trips 30% of the time.

A small manufacturing system processes two high volume parts: P1 and P2. Each of 50 units of P1 is first processed on M1 and then sent to machine M2 or M4, where it is further processed and then sent to M3 for final processing. In addition to P1, the manufacturing facility processes 60 units of P2, of which 30 are processed first on M1, and then machine M2. Because machine M3 can do the same processing as machine M1 for part P2, the remaining 30 units of part P2 are processed first on machine M3 and then sent to machine M2 for final processing. Two candidate Material Handling Systems, H1 and H2 with purchase costs 100,000 TL and 140,000 TL respectively, are being considered. The unit cost of transporting P1 and P2 on each of the MHSs between the machines are given in the following table. The corresponding transportation times per unit (in minutes) are provided in parentheses in the table. Assume that there are 7150 minutes in the planning period and each handling device is expected to make empty trips 30% of the time.

Determine the required MHS and assign the departmental moves to the selected MHS(s).

Hint: You should build an LP model and solve it by any optimization package.

M2 Mi Pi P2 Mi M3 M2 M4 (M3 From To M M2 M3 M4 P1 M H H2 7(10) 5(8) 8(5) 2(2) P M2 H H2 8(6) 4(5) P1 M4 H H2 8(8) 4(5) P2 Mi H H2 2(4) 1(2) P2 M3 H H2 20(6) 12(2)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts