Question: + A sudden increase in the demand for hard drives has left your company with insufficient capacity to meet demand. The company has seen

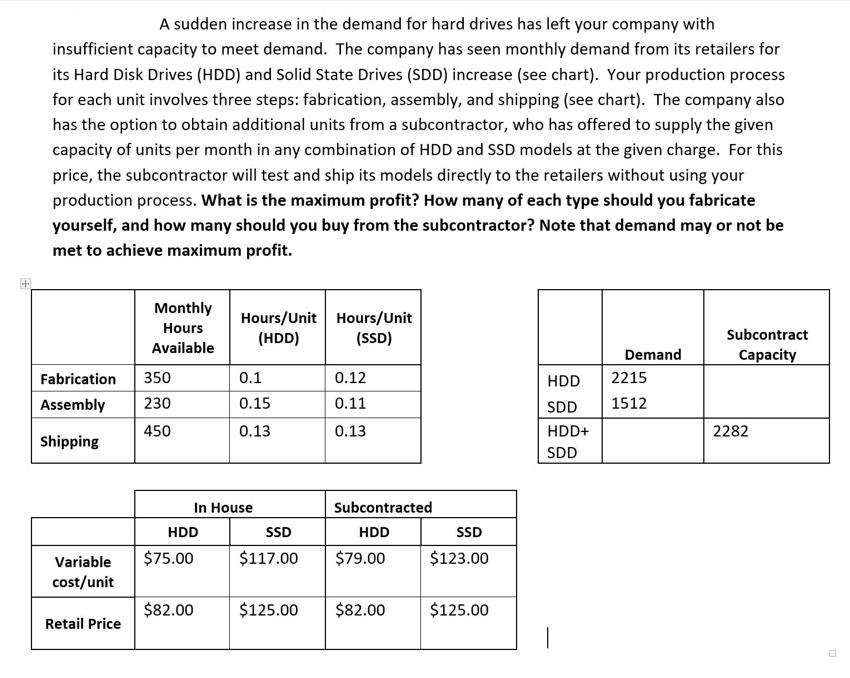

+ A sudden increase in the demand for hard drives has left your company with insufficient capacity to meet demand. The company has seen monthly demand from its retailers for its Hard Disk Drives (HDD) and Solid State Drives (SDD) increase (see chart). Your production process for each unit involves three steps: fabrication, assembly, and shipping (see chart). The company also has the option to obtain additional units from a subcontractor, who has offered to supply the given capacity of units per month in any combination of HDD and SSD models at the given charge. For this price, the subcontractor will test and ship its models directly to the retailers without using your production process. What is the maximum profit? How many of each type should you fabricate yourself, and how many should you buy from the subcontractor? Note that demand may or not be met to achieve maximum profit. Monthly Hours Available Fabrication 350 Assembly 230 450 Shipping Retail Price HDD Variable $75.00 cost/unit $82.00 Hours/Unit (HDD) 0.1 0.15 0.13 In House SSD $117.00 Hours/Unit (SSD) 0.12 0.11 0.13 Subcontracted HDD $79.00 $125.00 $82.00 SSD $123.00 $125.00 HDD SDD HDD+ SDD 1 Demand 2215 1512 Subcontract Capacity 2282

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts