Question: An MRP system is used to schedule each step. For motor assemblies, the lot size is 100 units and the lead time is one week.

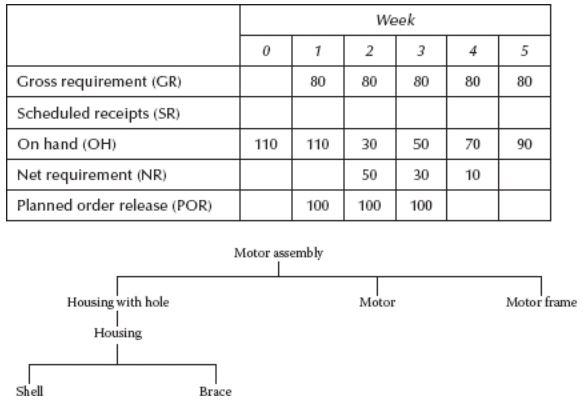

An MRP system is used to schedule each step. For motor assemblies, the lot size is 100 units and the lead time is one week. Eighty motors/wk are assembled. There are currently 110 units in stock. The MRP record for the motor assembly is as follows:

Assembly of the housing and drilling of the hole in the housing are done in two separate areas of the plant. The final motor assembly is done in a third area. It is proposed that the brace and shell assembly, drilling the hole, and final assembly of finished motors all be done in a single workcell. What would the BOM reflecting this change look like?

Answering Instruction:

Use the unit for D ( units/day), Q (units), C (days),and N (deliveries). Express your BOM answers in the format (D,Q,C,N) to be entered in the below box as follows: 300,20,3,1e.g. if your results are D = 300, Q = 20, C = 3, N = 1, enter 300,20,3,1

Week 0 1 2 3 4 5 80 80 80 80 80 Gross requirement (GR) Scheduled receipts (SR) On hand (OH) Net requirement (NR) Planned order release (POR) 110 110 30 50 70 90 50 30 10 100 100 100 Motor assembly Motor Motor frame Housing with hole 1 Housing Shell BraceStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts