Question: Anchor Praduce Suppllers Anchor Praduce Suppllers ( APS ) is a small but successful company in the man - made there, Industry. The company was

Anchor Praduce Suppllers

Anchor Praduce Suppllers APS is a small but successful company in the manmade there, Industry. The company was

heavlly dependent on the sales of Ravgoh, a product it had developed Itself, which accounted in for of total

sal

BayggR was used mainly In heavyduty clothing, although small quantities were used to produce industrial goods such

as tyrot, cord and industrial belting. Its main properties were very high wear resistance, thermal and electrica

Insulatlan.

In the company had developed a new product, JegolepA, JejJlsoe, had all the propertles of Bayggh but was

superlor In Its heat resistant quallties. It was hoped that this additlonal property would oge un new dothing uses

eg a substitute for mineral wool clothing, added to nightwear to Improve Its Infiammabllty, and new Industrial uses

in thermal and electrical linsulatian.

By late the major technical and engineering problem assoclated with bulk production of Tegojsofk, seemed to

have been solved and the company had set up a working party to put forward proposals on how the new product

should be phased Into the company's activities.

The basic production method of BaygsR and Tardegpa, was like that of most manmade Wages To make a manmade

there, an allbased organic chemicals is polymerlzed a process of foining several malecules into a long chain In

conditions of Intense pressure and heat, often by the addition of a sultable catalyst. This polymerization takes place in

large autodaves an industrial pressure cooker The polymer is then extruded forced through a nozzie rapldly

cooled and then elther spun on to cones or collected in bales. The raw materlals for Baygen and TAgxleqa, were

produced in the UK

Bayggh facillties

Baygg was produced at three factories in the UK: Jefolde, Bradford and Dumfries. The largest site was Jeggige,with

three plants. There was one plant at each of the other two siltes.

All five production plants had a design capacty of million kg per year of Baygg. However, after allowing for

maintenance and an annual shutdown, expected output was million kg per year. Each plant operated on a hours

per day, days per week basks.

Proposed TefoleroA facillties

Tepolsofiaproductlon process was very simllar to that used for Baygg but a tatally new type of polymerization unlt

was needed prlor to the extrusion stage. ApS had approached Afoboalt, Englneering Company, an International

chemical plant construction company, for help on a largescale plant design of the new unlt. Together they had

produced and tested an acceptable design.

Acquiring TarolERa capscity

There were two ways of acquiring TAJTlepa, Capacity. ASP could convert a Baygg plant, or they could construct an

entirely new plant. For a conversian, the new polymer unlt would need to be constructed first. When complete it would

be connected to the extruslon unit which would require milnor conversion. At least two years would be needed elther

The company Chlef Executive officer had been quoted as saying.

The creation of an entirely new site would lincrease the complexities of multisite operation to an unacceptable level.

Conwersely, the complete closure of one of the three existing sites Is I consider, a waste of the manpower and

physical resources that we have Invested in that location. I belleve expansion could take place at one, two or all af the

exlsting sltes.

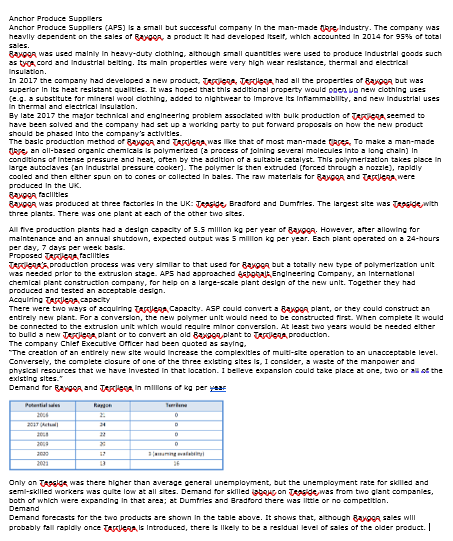

Demand for BavgoR and Jejrlsog in millions of ing per wear

Only on TAgglge was there higher than average general unemployment, but the unemployment rate for slilled and

semlskilled workers was quite low at all sites. Demand for skilled sgopu on Tegsige,was from two glant compsnies,

both of which were exponding in that area; at Dumfries and Eradford there was ilttle or no competition.

Demand

Demand forecasts for the two products are shown In the table above. It shows that, aithough Raypgh sales will

probably fall rapldly once TArolepa, is Introduced, there is likely to be a residual level of saies of the older product.

Longterm capacity plan:

What are the measures of capacity

what are the economies of scale

What is the timing and sizing strategy

What is the systematic approach

What are the tools for capacity planning

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock