Question: Answer fully please. Steps provided X double bar R bar UCL x bar Show calculation: LCL x bar Show calculation: UCL R Show calculation: LCL

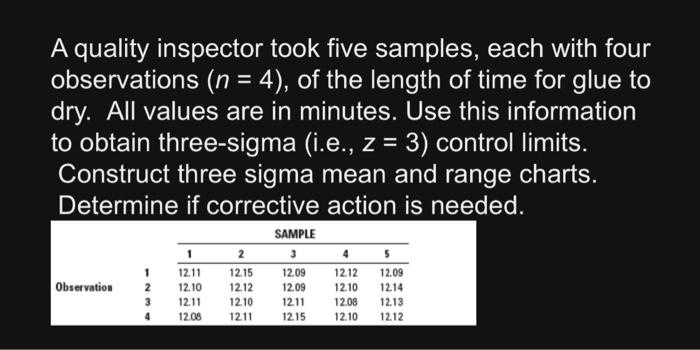

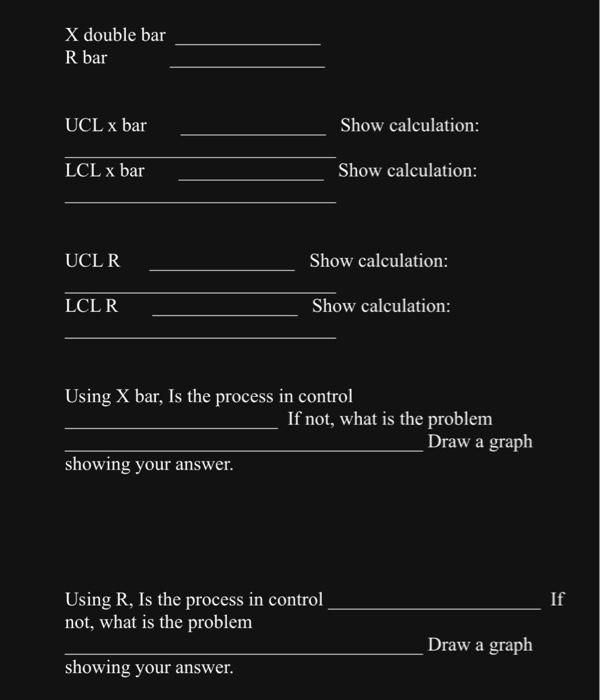

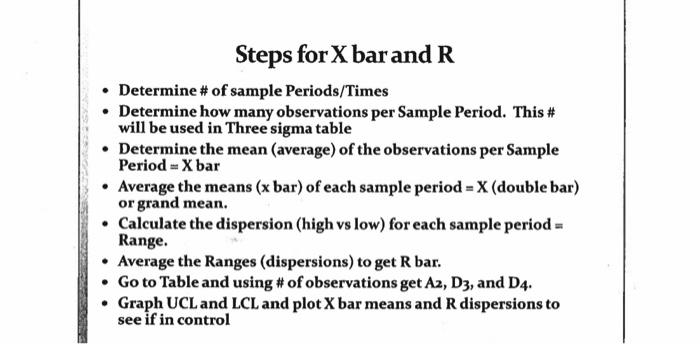

X double bar R bar UCL x bar Show calculation: LCL x bar Show calculation: UCL R Show calculation: LCL R Show calculation: Using X bar, Is the process in control If not, what is the problem Draw a graph showing your answer. Using R, Is the process in control If not, what is the problem Draw a graph showing your answer. Steps for X bar and R - Determine \# of sample Periods/Times - Determine how many observations per Sample Period. This \# will be used in Three sigma table - Determine the mean (average) of the observations per Sample Period =X bar - Average the means ( x bar) of each sample period = X (double bar) or grand mean. - Calculate the dispersion (high vs low) for each sample period = Range. - Average the Ranges (dispersions) to get R bar. - Go to Table and using \# of observations get A2,D3, and D4. - Graph UCL and LCL and plot X bar means and R dispersions to see if in control A quality inspector took five samples, each with four observations (n=4), of the length of time for glue to dry. All values are in minutes. Use this information to obtain three-sigma (i.e., z=3 ) control limits. Construct three sigma mean and range charts. Determine if corrective action is needed

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts