Question: Answer these details by analyzing data below. FernFuel, A good candidate for the contract is FernFuel, a small proprietary limited manufacturer located in Glenbrook, a

Answer these details by analyzing data below.

FernFuel, A good candidate for the contract is FernFuel, a small proprietary limited manufacturer located in Glenbrook, a half hour drive from Auckland on the North Island of New Zealand. The company focuses exclusively on the design and production of data projector devices. The team discovered this company almost by accident. A team member was browsing a trade journal and saw FernFuel advertisement. When the team further researched the company, they found IT World and Technology Today magazines had praised the companys products and innovative abilities in several recent editions. When the team visited the facility, the team was surprised at its small size and by the fact that it is located in an old warehouse. FernFuel President, Piper Owen met with the team in person. She explained that she was a graduate of Harvard in electrical engineering with an MBA from the Sydney Business School and had decided to start her own company after working overseas for IBM and Apple for 15 years. The company entered the digital data projector market four years ago and has produced miniature data projectors for just over a year. During this time, however, FernFuel has established a reputation for delivery reliability and innovation. The President seemed extremely focused on statistics and measurements, explaining that their delivery metrics were measured as door to door, and very stringent on DIFOTIS, so if one item had a defect or was one day late, then the whole delivery was measured as a non-conformance. The President explained that FernFuel success was based largely on its commitment to develop new technology, especially technology that enhanced product reliability. She also claimed that she knew every business customer personally. Some of the team expressed concerns that the company was way too small for Alset to deal with a posed a significant risk to our business. The company was definitely a small growing entity (with just under 4% of global market share), but they expressed their intent to focus more on the business mobile computer industry as opposed to the home consumer computer industry, and intended to concentrate on the Australia and New Zealand geographies. Everyone in the plant seemed highly motivated, and, except for the president, the team did not see any person who appeared over the age of 35. There was a high number of Maori workers, and there were many signs about upcoming ceremonies and community events focusing on the Maori community. The President explained that New Zealand was a progressive country, and seemed proud of the fact that New Zealand had a female Prime Minister before Australia had, and the first western leader ever to be pregnant in office. She also explained that New Zealand was at the forefront of environmentally friendly industry, with carbon emissions taxes and a high percentage of the country being powered by hydro- electric plants. The President explained that the facility had a zero waste methodology and was powered by wind turbine energy. The President was particularly excited about the possibility of working with Alset, and promised to work with them closely on this contract and for any new product lines. She offered that during the selection process she would be willing to bring a small team to Alset premises to talk to manufacturing, R&D and engineering to assist in the design of the operations. In particular, she emphasized that she had been to a number of manufacturing operations and could discuss best practices in factory layout, manufacturing improvements and other technology improvements that were happening in the industry for mobile devices. When asked if her firm would have any problem in meeting demand should they receive the contract, she hesitated before answering. She admitted that this contract would be the largest in FernFuel relatively short history. She also indicated that several international buying teams were also going to be sending teams to evaluate FernFuel within the next month. However, she assured the Alset team that she would do whatever it took to maintain reliable delivery schedules if FernFuel received a contract. She also indicated that given assurance of future supply, she would consider further investments in R&D and facilities to expand production. Interestingly, it appeared that the production lines were experiencing some problems during the team's visit, as they were shut down for nearly four hours! The President introduced them to line staff by name as she walked around, and even congratulated a team of people who seemed to be working particularly safely. There were graphs and charts indicating safe work practices and a number of safety alerts and procedures on noticeboards as they walked around. The President had scheduled a meeting with the designer and technicians on the technical specifications and their initial implementation schedule should they gain the business. To be extra diligent in ensuring tooling was perfect and allowing time for adequate ramp-up, the time to start real production for the new data projector would be approximately 3 months. Lead time was two weeks after ramp up to when Alset could receive the first delivery, and then batches could be dispatched each fortnight from the site. The Logistics manager explained with a high level of excitement and passion that they had quoted the packaging and delivery requirements by transporting the miniature data projectors by a custom designed tailored polypropylene pallet that would protect the product in transit and allow for lower order quantities at an economical cost. This packaging was reusable and recyclable, and would ensure no customs issues or environmental concerns of treated timber pallets. The pallets collapsed for return transport and his proposal was to have the pallets returned to their premises. He also believed there would be less customs expenses due to the packaging not requiring fumigation or additional checks at the Australian clearance docks. The tooling cost and the project process had been detailed out and discussed with the Alset team by the Chief Engineer. The comment from the President was that they had conservatively estimated the tooling cost to be a maximum of $1.7 million, however if they were able to come in under budget, she would only be passing the actual costs by an open book invoicing arrangement up to that amount. Relevant FernFuel data from their tender response include: DAT quoted price = $143 per unit Ramp up time = conservatively 3 months Delivery lead time = 2 weeks (from time of order to day received) Current utilised capacity = 83% Current installed capacity = 4 million On-time delivery record = 93.5% on-time (but measured as DIFOTIS) Quality = from experience 13,000 defects ppm as a maximum on any initial orders, with any issues usually attributed to tooling aspects that would be worked out within the first month during pilot testing, dropping to well less of this ongoing Minimum batch size = 4,000 units for optimizing transport options on a purpose designed pallet, which could be recycled and reused Price basis = DAT = Delivered at Terminal to Sydney (Port Botany), with customs and duties payable, expected to be low Tooling cost = $1,655,000 as a maximum, downside to budget maximum to Alset through an open book arrangement Relevant Alset data specific to FernFuel include: Frequency of Shipment = Fortnightly Estimated day of arrival = Every second Thursday Ordering cost per order = $160 due to individual purchase orders fortnightly Receiving cost per delivery = $160 for unloading container and inspection Land transport (truck Sydney to Wollongong direct) = $2,600 each pallet including load / unload and return transport of the pallets Insurance = $0.14 per unit while in transit, including the pallets Duties / customs / tariffs = $0.68 per unit due to the lower tariffs paid on New Zealand goods and lower customs clearance due to the pallet design

FernFuel, A good candidate for the contract is FernFuel, a small proprietary limited manufacturer located in Glenbrook, a half hour drive from Auckland on the North Island of New Zealand. The company focuses exclusively on the design and production of data projector devices. The team discovered this company almost by accident. A team member was browsing a trade journal and saw FernFuel advertisement. When the team further researched the company, they found IT World and Technology Today magazines had praised the companys products and innovative abilities in several recent editions. When the team visited the facility, the team was surprised at its small size and by the fact that it is located in an old warehouse. FernFuel President, Piper Owen met with the team in person. She explained that she was a graduate of Harvard in electrical engineering with an MBA from the Sydney Business School and had decided to start her own company after working overseas for IBM and Apple for 15 years. The company entered the digital data projector market four years ago and has produced miniature data projectors for just over a year. During this time, however, FernFuel has established a reputation for delivery reliability and innovation. The President seemed extremely focused on statistics and measurements, explaining that their delivery metrics were measured as door to door, and very stringent on DIFOTIS, so if one item had a defect or was one day late, then the whole delivery was measured as a non-conformance. The President explained that FernFuel success was based largely on its commitment to develop new technology, especially technology that enhanced product reliability. She also claimed that she knew every business customer personally. Some of the team expressed concerns that the company was way too small for Alset to deal with a posed a significant risk to our business. The company was definitely a small growing entity (with just under 4% of global market share), but they expressed their intent to focus more on the business mobile computer industry as opposed to the home consumer computer industry, and intended to concentrate on the Australia and New Zealand geographies. Everyone in the plant seemed highly motivated, and, except for the president, the team did not see any person who appeared over the age of 35. There was a high number of Maori workers, and there were many signs about upcoming ceremonies and community events focusing on the Maori community. The President explained that New Zealand was a progressive country, and seemed proud of the fact that New Zealand had a female Prime Minister before Australia had, and the first western leader ever to be pregnant in office. She also explained that New Zealand was at the forefront of environmentally friendly industry, with carbon emissions taxes and a high percentage of the country being powered by hydro- electric plants. The President explained that the facility had a zero waste methodology and was powered by wind turbine energy. The President was particularly excited about the possibility of working with Alset, and promised to work with them closely on this contract and for any new product lines. She offered that during the selection process she would be willing to bring a small team to Alset premises to talk to manufacturing, R&D and engineering to assist in the design of the operations. In particular, she emphasized that she had been to a number of manufacturing operations and could discuss best practices in factory layout, manufacturing improvements and other technology improvements that were happening in the industry for mobile devices. When asked if her firm would have any problem in meeting demand should they receive the contract, she hesitated before answering. She admitted that this contract would be the largest in FernFuel relatively short history. She also indicated that several international buying teams were also going to be sending teams to evaluate FernFuel within the next month. However, she assured the Alset team that she would do whatever it took to maintain reliable delivery schedules if FernFuel received a contract. She also indicated that given assurance of future supply, she would consider further investments in R&D and facilities to expand production. Interestingly, it appeared that the production lines were experiencing some problems during the team's visit, as they were shut down for nearly four hours! The President introduced them to line staff by name as she walked around, and even congratulated a team of people who seemed to be working particularly safely. There were graphs and charts indicating safe work practices and a number of safety alerts and procedures on noticeboards as they walked around. The President had scheduled a meeting with the designer and technicians on the technical specifications and their initial implementation schedule should they gain the business. To be extra diligent in ensuring tooling was perfect and allowing time for adequate ramp-up, the time to start real production for the new data projector would be approximately 3 months. Lead time was two weeks after ramp up to when Alset could receive the first delivery, and then batches could be dispatched each fortnight from the site. The Logistics manager explained with a high level of excitement and passion that they had quoted the packaging and delivery requirements by transporting the miniature data projectors by a custom designed tailored polypropylene pallet that would protect the product in transit and allow for lower order quantities at an economical cost. This packaging was reusable and recyclable, and would ensure no customs issues or environmental concerns of treated timber pallets. The pallets collapsed for return transport and his proposal was to have the pallets returned to their premises. He also believed there would be less customs expenses due to the packaging not requiring fumigation or additional checks at the Australian clearance docks. The tooling cost and the project process had been detailed out and discussed with the Alset team by the Chief Engineer. The comment from the President was that they had conservatively estimated the tooling cost to be a maximum of $1.7 million, however if they were able to come in under budget, she would only be passing the actual costs by an open book invoicing arrangement up to that amount. Relevant FernFuel data from their tender response include: DAT quoted price = $143 per unit Ramp up time = conservatively 3 months Delivery lead time = 2 weeks (from time of order to day received) Current utilised capacity = 83% Current installed capacity = 4 million On-time delivery record = 93.5% on-time (but measured as DIFOTIS) Quality = from experience 13,000 defects ppm as a maximum on any initial orders, with any issues usually attributed to tooling aspects that would be worked out within the first month during pilot testing, dropping to well less of this ongoing Minimum batch size = 4,000 units for optimizing transport options on a purpose designed pallet, which could be recycled and reused Price basis = DAT = Delivered at Terminal to Sydney (Port Botany), with customs and duties payable, expected to be low Tooling cost = $1,655,000 as a maximum, downside to budget maximum to Alset through an open book arrangement Relevant Alset data specific to FernFuel include: Frequency of Shipment = Fortnightly Estimated day of arrival = Every second Thursday Ordering cost per order = $160 due to individual purchase orders fortnightly Receiving cost per delivery = $160 for unloading container and inspection Land transport (truck Sydney to Wollongong direct) = $2,600 each pallet including load / unload and return transport of the pallets Insurance = $0.14 per unit while in transit, including the pallets Duties / customs / tariffs = $0.68 per unit due to the lower tariffs paid on New Zealand goods and lower customs clearance due to the pallet design

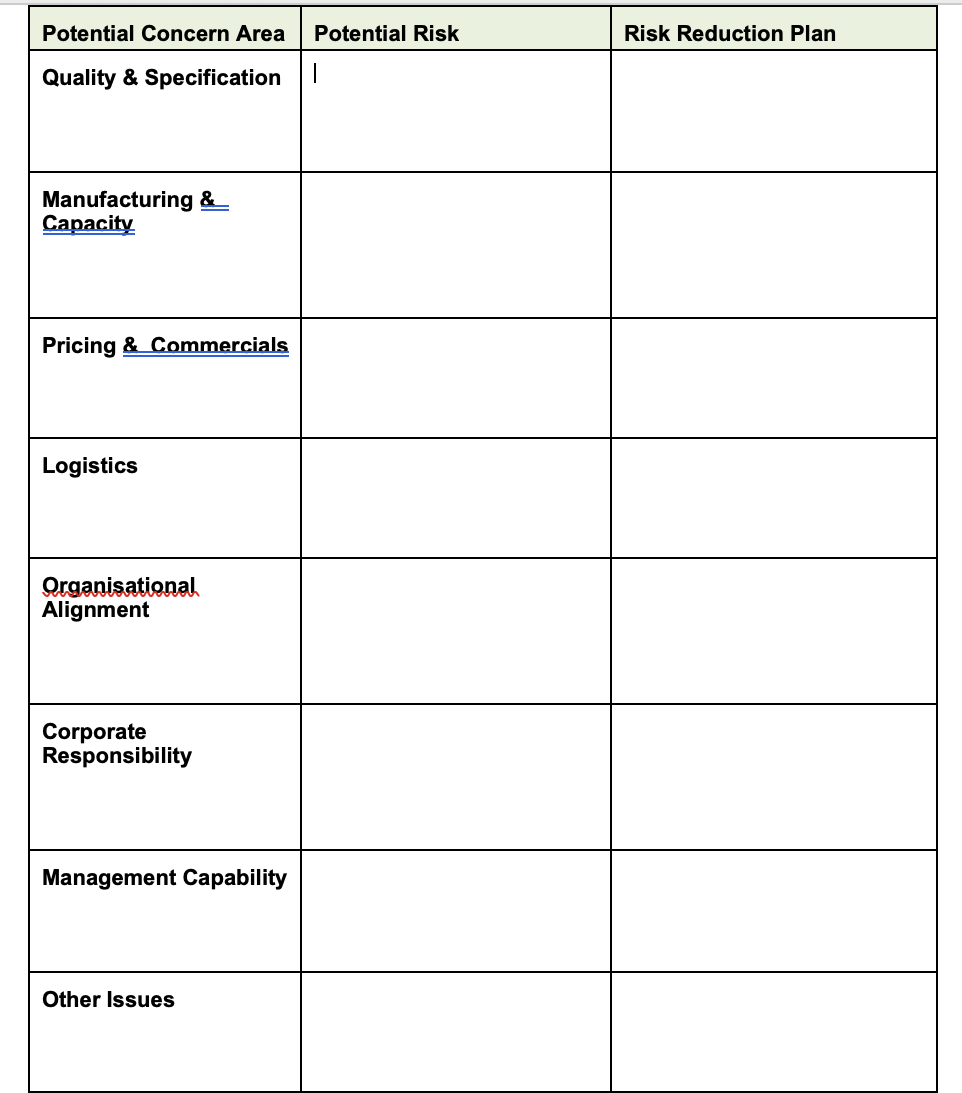

\begin{tabular}{|l|l|l|} \hline Potential Concern Area & Potential Risk & Risk Reduction Plan \\ \hline Quality \& Specification & I & \\ \hline Manufacturing&Capacity & & \\ \hline Pricing \& Commercials & & \\ \hline Logistics & & \\ \hline Organisational & & \\ \hline Alignment & & \\ \hline Oother Issues & & \\ \hline Resporate & & \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts