Question: Background Industrial and systems engineers often work on logistics problems. Logistics can range from supply chain management and production logistics to distribution logistics. Problem Statement

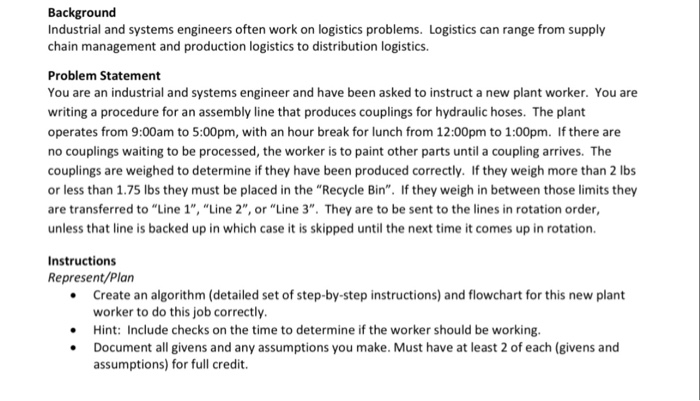

Background Industrial and systems engineers often work on logistics problems. Logistics can range from supply chain management and production logistics to distribution logistics. Problem Statement You are an industrial and systems engineer and have been asked to instruct a new plant worker. You are writing a procedure for an assembly line that produces couplings for hydraulic hoses. The plant operates from 9:00am to 5:00pm, with an hour break for lunch from 12:00pm to 1:00pm. If there are no couplings waiting to be processed, the worker is to paint other parts until a coupling arrives. The couplings are weighed to determine if they have been produced correctly. If they weigh more than 2 lbs or less than 1.75 lbs they must be placed in the "Recycle Bin". If they weigh in between those limits they are transferred to "Line 1", "Line 2", or "Line 3". They are to be sent to the lines in rotation order, unless that line is backed up in which case it is skipped until the next time it comes up in rotation. Instructions Represent/Plan Create an algorithm (detailed set of step-by-step instructions) and flowchart for this new plant worker to do this job correctly .Hint: Include checks on the time to determine if the worker should be working Document all givens and any assumptions you make. Must have at least 2 of each (givens and assumptions) for full credit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts