Question: BLUE Merge Center Inse Conditional Formatas Call Formatting Table Sty Styles Font Alignment Number B E F 6 M ming Activity: EOQ for optimal purchasing

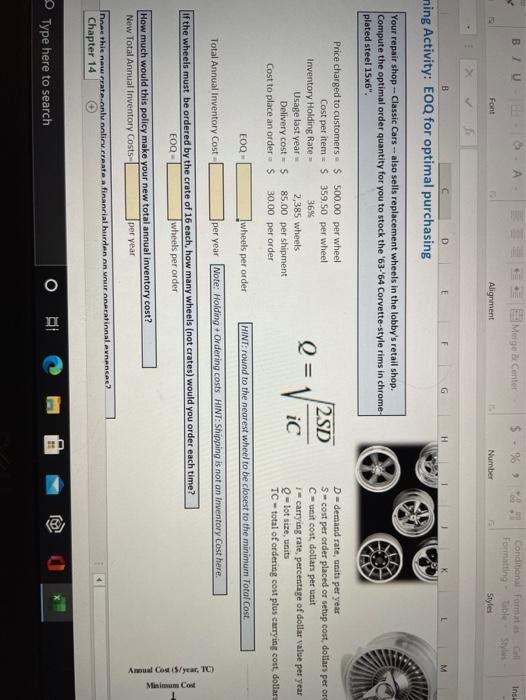

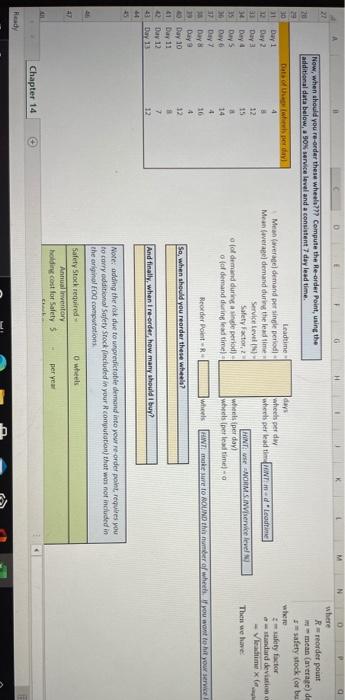

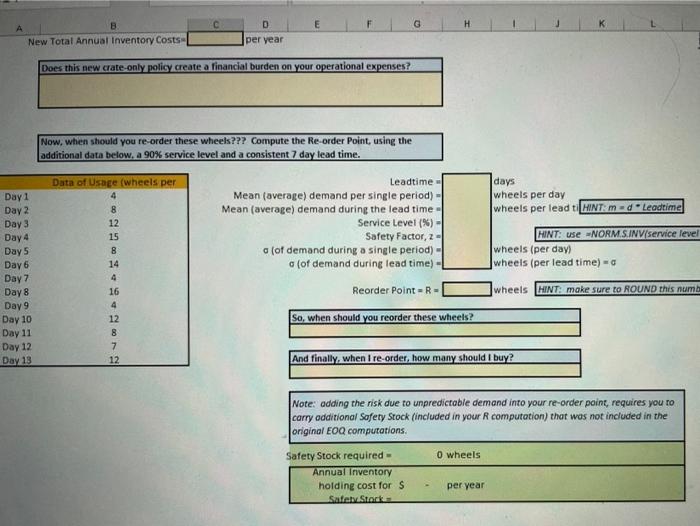

BLUE Merge Center Inse Conditional Formatas Call Formatting Table Sty Styles Font Alignment Number B E F 6 M ming Activity: EOQ for optimal purchasing Your repair shop -- Classic Cars - also sells replacement wheels in the lobby's retail shop. compute the optimal order quantity for you to stock the '63-64 Corvette-style rims in chrome plated steel 15x6". 2SD Price charged to customers - $ 500.00 per wheel Cost per item= S 359,50 per wheel Inventory Holding Rate 36% Usage last year 2,385 wheels Delivery cost - 5 85.00 per shipment Cost to place an orders 30.00 per order = D-demand rate, units per year S-cost per order placed or setup cost, dollars per ore Cunit cost, dollars per unit 1 - carrying rate, percentage of dollar value per year Olot size, units TC - total of ordering cost plus carrying cost, dollar iC EOQ wheels per order HINT: round to the nearest wheel to be closest to the minimum Total Cost. Total Annual Inventory Cost per year Note: Holding Ordering costs HINT: Shipping is not an inventory Cost here. If the wheels must be ordered by the crate of 16 each, how many wheels (not crates) would you order each time? EOQ wheels per order Anual Cod (S/year, TC) Minimum Con How much would this policy make your new total annual inventory cost? New Total Annual Inventory Costs per year Innecthie now rate.nl noliru.create a financial burden on uur onerational evnence? Chapter 14 Type here to search O . N M G Now, when should you re-order these wheel777 Compute the Re-order Point, using the additional data below, 90service level and a consistent 7 day lead time where Rreorder point mean (average) de safety stock (or bu 20 10 Dat wows per day! where 11 12 safety factor standard deviation Vadime x la 33 34 Leadtime Mean (average demand per single period Mean coverage demand during the lead time Service Level Safety Factor 2 alol demand during in de period of demand during lead time) Day 1 Day 2 Day Day Days Day 6 Day days wheels per day wheels a lead to Talon HIN VORMS INViservice lewe wheels per day Wheels perlesd time Then we have 14 17 4 Daya 10 Rro der Point Wheels HT, make sure to ROUND Thumber of wheels you want it owice + 12 So, when should you reorder these wheel 19 Day 45. Day 10 1 Day 11 Day 12 23 Day 1 7 12 And finally, when I re-order how many should I buy? Note adding the risk due to unpredictable demand into your re-order point, requires you to carry additional Safety Stock included in your computation) that was not included in the original comitations O wheels 7 Safety Stock required Annual inventory holding cost for Safety S ca per year Chapter 14 Heady D G H B New Total Annual Inventory Costs per year Does this new crate only policy create a financial burden on your operational expenses? Now, when should you re-order these wheels??? Compute the Re-order Point, using the additional data below, a 90% service level and a consistent 7 day lead time. Data of Usage (wheels per Leadtime 4 days wheels per day wheels per lead to HINT: m - d Leadtime Mean (average) demand per single period) - Mean (average) demand during the lead time- Service Level (%) - 8 12 15 Safety Factor, z HINT: use -NORM.S.INV/service level wheels (per day) wheels (per lead time) -G 14 Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7 Day 8 Day 9 Day 10 Day 11 Day 12 Day 13 4 clof demand during a single period) - . (of demand during lead time) - Reorder Point =R- So, when should you reorder these wheels? 16 wheels HINTH make sure to ROUND this numb 4 12 8 7 12 And finally, when I re-order, how many should I buy? Note: adding the risk due to unpredictable demand into your re-order point, requires you to carry additional Safety Stock (included in your computation) that was not included in the original EOQ computations O wheels Safety Stock required Annual Inventory holding cost for S Suite Stark per year BLUE Merge Center Inse Conditional Formatas Call Formatting Table Sty Styles Font Alignment Number B E F 6 M ming Activity: EOQ for optimal purchasing Your repair shop -- Classic Cars - also sells replacement wheels in the lobby's retail shop. compute the optimal order quantity for you to stock the '63-64 Corvette-style rims in chrome plated steel 15x6". 2SD Price charged to customers - $ 500.00 per wheel Cost per item= S 359,50 per wheel Inventory Holding Rate 36% Usage last year 2,385 wheels Delivery cost - 5 85.00 per shipment Cost to place an orders 30.00 per order = D-demand rate, units per year S-cost per order placed or setup cost, dollars per ore Cunit cost, dollars per unit 1 - carrying rate, percentage of dollar value per year Olot size, units TC - total of ordering cost plus carrying cost, dollar iC EOQ wheels per order HINT: round to the nearest wheel to be closest to the minimum Total Cost. Total Annual Inventory Cost per year Note: Holding Ordering costs HINT: Shipping is not an inventory Cost here. If the wheels must be ordered by the crate of 16 each, how many wheels (not crates) would you order each time? EOQ wheels per order Anual Cod (S/year, TC) Minimum Con How much would this policy make your new total annual inventory cost? New Total Annual Inventory Costs per year Innecthie now rate.nl noliru.create a financial burden on uur onerational evnence? Chapter 14 Type here to search O . N M G Now, when should you re-order these wheel777 Compute the Re-order Point, using the additional data below, 90service level and a consistent 7 day lead time where Rreorder point mean (average) de safety stock (or bu 20 10 Dat wows per day! where 11 12 safety factor standard deviation Vadime x la 33 34 Leadtime Mean (average demand per single period Mean coverage demand during the lead time Service Level Safety Factor 2 alol demand during in de period of demand during lead time) Day 1 Day 2 Day Day Days Day 6 Day days wheels per day wheels a lead to Talon HIN VORMS INViservice lewe wheels per day Wheels perlesd time Then we have 14 17 4 Daya 10 Rro der Point Wheels HT, make sure to ROUND Thumber of wheels you want it owice + 12 So, when should you reorder these wheel 19 Day 45. Day 10 1 Day 11 Day 12 23 Day 1 7 12 And finally, when I re-order how many should I buy? Note adding the risk due to unpredictable demand into your re-order point, requires you to carry additional Safety Stock included in your computation) that was not included in the original comitations O wheels 7 Safety Stock required Annual inventory holding cost for Safety S ca per year Chapter 14 Heady D G H B New Total Annual Inventory Costs per year Does this new crate only policy create a financial burden on your operational expenses? Now, when should you re-order these wheels??? Compute the Re-order Point, using the additional data below, a 90% service level and a consistent 7 day lead time. Data of Usage (wheels per Leadtime 4 days wheels per day wheels per lead to HINT: m - d Leadtime Mean (average) demand per single period) - Mean (average) demand during the lead time- Service Level (%) - 8 12 15 Safety Factor, z HINT: use -NORM.S.INV/service level wheels (per day) wheels (per lead time) -G 14 Day 1 Day 2 Day 3 Day 4 Day 5 Day 6 Day 7 Day 8 Day 9 Day 10 Day 11 Day 12 Day 13 4 clof demand during a single period) - . (of demand during lead time) - Reorder Point =R- So, when should you reorder these wheels? 16 wheels HINTH make sure to ROUND this numb 4 12 8 7 12 And finally, when I re-order, how many should I buy? Note: adding the risk due to unpredictable demand into your re-order point, requires you to carry additional Safety Stock (included in your computation) that was not included in the original EOQ computations O wheels Safety Stock required Annual Inventory holding cost for S Suite Stark per year