Question: Excel File Edit View Insert Format Tools Data Window Help Sun Jun 27 11:41 PM A Week 4 - A-Learning Activity (1) Q Search Sheet

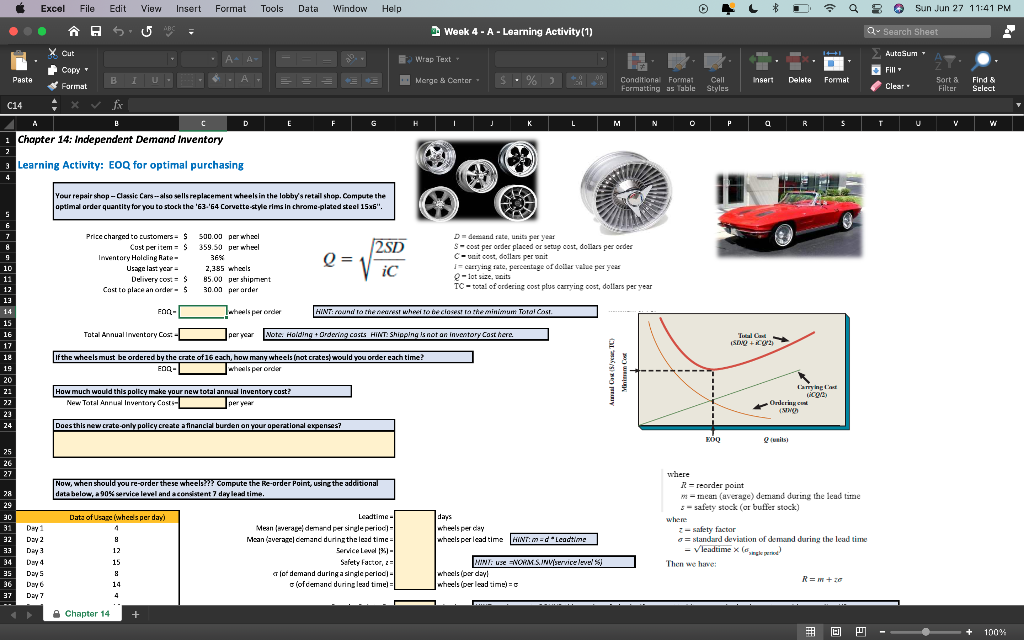

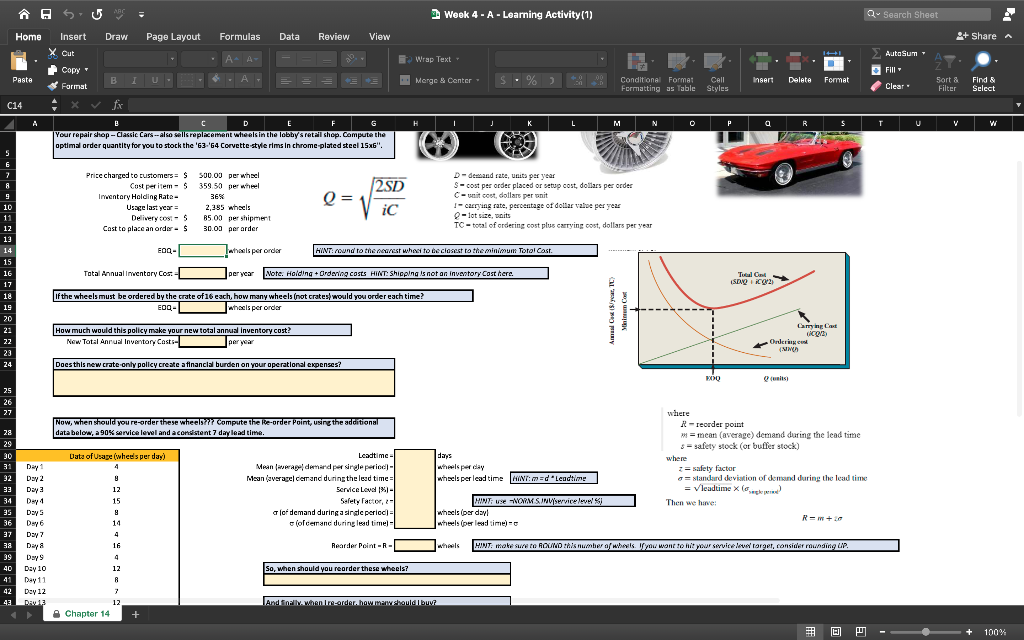

Excel File Edit View Insert Format Tools Data Window Help Sun Jun 27 11:41 PM A Week 4 - A-Learning Activity (1) Q Search Sheet X Cut AutoSum- - Wrap Text Copy - Fill Paste B I U Merge & Center - Insert Delete Format Cell Styles Format Conditional Format Formatting as Table Clear Sort & Filter Find & Select C14 fix B D E F G T K L L M 0 P a R S T V W 1 Chapter 14: Independent Demand Inventory 3 Learning Activity: EOQ for optimal purchasing 2 4 . Your repair shop - Classic Cars--also sells replacement wheels in the lobby's retail shop. Compute the optimal order quantity for you to stock the '63-64 Corvette-style rims in chrome-plated steel 15x6". 25D Price changed to customers. S Custper items Inventory Holding Rate Usage last year Delivery tost S Cast to place an order - $ 500.00 per what 359.50 per wheel 365 2,355 wheels 85.00 per shipment 30.00 per order Q= D-deand rate, unita per year S-cost per order placed or setup cost, dollars per order C-witcost, dollars per unit 1 carrying rate, percentage of dollar vale per year Qlot size, bits TC total of ordering cost plus carrying cost, dollars per year 10 11 12 iC FON- wheelsperonder HINT: round to the crear when to be closest to the minimurti Totol Cast. Total Annual Inventory Cos per year Mote. Holding + Ordering costs HINT: Shipping is not an inventory Cost here. Tula SON+2002) 13 14 15 16 17 18 19 20 21 22 23 24 If the wheels must be ordered by the crate of 16 cach, how many wheels (not crates would you order cach time? E00- whisper order Caming How much would this policy make your new total annual Inventory cost? New Total Annual Inventary Costs per year Onderhoud SI Does this new crate-only policy create a financial burden on your operational expenses? FOO 25 26 27 Now, when should you re-order these wheels??? Compute the Re-order Point, using the additional data below, a 90% service level and a consistent 7 day lead time. 28 29 Data of Usage (wheels per day) days wheels per day wheels per lead time WINT: MdLeadtime g. 30 31 32 33 34 35 36 37 Day Day 2 Day Day 4 Days Day Day 7 where R = reorder point mmean (average) demand during the lead time s-safety stock (or buffer stock) where 2- sadety factor o = standard deviation of demand during the lead time - leadtime x Then we have REM + ze Leadtime Meanwerapel demand per single period Mean (average cerrand during the lead time Serviceleve 141 Safety Factor, el lot demand during a single period lofcerranc during lead time) = 12 15 MUNT: wse ACIM SINV'service levels whols per day whsels (per lead time) = 14 Chapter 14 + + 100% ARO Week 4 - A-Learning Activity (1) Q Search Sheet Home Draw Page Layout Formulas Data Review View 9+ Share A Insert X Cut Wrap Text AutoSum A-A- * A Fill Copy r Format Paste B U- Merge & Center - Insert Delta Format Conditional Format Formatting as Table Call Styles Clear Sort & Filter Find & Select C14 . fix A T L M 0 P a R T U V W B D E F Your repair shop - Classic Cars--also sells replacement wheels in the lobby's retail shop. Compute the optimal order quantity for you to stock the '63-64 Corvette style rims in chrome-plated steel 15x6". Price charged to customers Cost pertem - 5 Inventory Holding Rate Usage last year Delivery costs Cast to place an order - $ S00.00 per wheel 359.50 per wheel 3ES 2,395 wheels 05.03 per shipment 30.00 per arder Q= 2SD iC D-demand rate, unita per year S-cost per order placed or setup cost, dollars per order C-nicot, dollars per unit 1 - carrying rate, percentage of dollar valve per year Olot size, bits TC-total of ordering cost plus carrying cost, dollars per year 11 12 EO- wheels per order HINT: round to the nearest whes to be closest to the minimum Total Cast. 13 14 15 16 Total Annual Inventory Com per year Note: Holding + Ordering costs HINT: Shipping is not an inventory Cost here. Tel SDU CO2 17 10 19 If the wheels must be ordered by the crate of 16 each, how many wheels (not crates would you order each time? EDO- whosis per order mual Cos you, IC How much would this policy make your new total annual inventory cost? New Total Annual Inventory Cast: per year Carrying out COV 22 23 Orderingen 24 Does this new crate only policy create a financial burden on your operational expenses EXO Dumilisi 25 26 27 Now, when should you re-order these wheel Compute the Ke-order Point, using the additional data below, a 90% service level and acondistent 7 day lead time. Date of Usage (wheels per day) days whelper day wheels per lead time MINT: m=dLeadtime where R- reorder point = mean (average) demand during the lead time s = safety stock (or buffer stock) where z = safety factor a = standard deviation of demand during the lead time = vleadtime x la Then we have 12 15 Leadtime- Meanwerpe demander urgle period Mean (averagel cerrand during the lead time Service Level 1 - Safety Factor, , tr| Glof demand during aside period lolcemand during lead time) 28 29 30 31 32 Day 2 33 Day 2 34 Day 1 35 Days 36 Day 6 37 Day 7 2 38 Daya 39 Days 40 Day 10 41 Day 11 42 Day 12 43 DEV13 HINT: we WONOM SIN Service levels wheels per day wheels (perlesdime) R 14 16 Rearder Peint-R- whals WINT moke sure to ROUND this number of wheels. If you want to hit your service target, consider munding Up So, when should you reorder these wheels? 4 12 R 7 12 Chapter 14 And finally when re-arder. how many should I buv + + 100% Excel File Edit View Insert Format Tools Data Window Help Sun Jun 27 11:41 PM A Week 4 - A-Learning Activity (1) Q Search Sheet X Cut AutoSum- - Wrap Text Copy - Fill Paste B I U Merge & Center - Insert Delete Format Cell Styles Format Conditional Format Formatting as Table Clear Sort & Filter Find & Select C14 fix B D E F G T K L L M 0 P a R S T V W 1 Chapter 14: Independent Demand Inventory 3 Learning Activity: EOQ for optimal purchasing 2 4 . Your repair shop - Classic Cars--also sells replacement wheels in the lobby's retail shop. Compute the optimal order quantity for you to stock the '63-64 Corvette-style rims in chrome-plated steel 15x6". 25D Price changed to customers. S Custper items Inventory Holding Rate Usage last year Delivery tost S Cast to place an order - $ 500.00 per what 359.50 per wheel 365 2,355 wheels 85.00 per shipment 30.00 per order Q= D-deand rate, unita per year S-cost per order placed or setup cost, dollars per order C-witcost, dollars per unit 1 carrying rate, percentage of dollar vale per year Qlot size, bits TC total of ordering cost plus carrying cost, dollars per year 10 11 12 iC FON- wheelsperonder HINT: round to the crear when to be closest to the minimurti Totol Cast. Total Annual Inventory Cos per year Mote. Holding + Ordering costs HINT: Shipping is not an inventory Cost here. Tula SON+2002) 13 14 15 16 17 18 19 20 21 22 23 24 If the wheels must be ordered by the crate of 16 cach, how many wheels (not crates would you order cach time? E00- whisper order Caming How much would this policy make your new total annual Inventory cost? New Total Annual Inventary Costs per year Onderhoud SI Does this new crate-only policy create a financial burden on your operational expenses? FOO 25 26 27 Now, when should you re-order these wheels??? Compute the Re-order Point, using the additional data below, a 90% service level and a consistent 7 day lead time. 28 29 Data of Usage (wheels per day) days wheels per day wheels per lead time WINT: MdLeadtime g. 30 31 32 33 34 35 36 37 Day Day 2 Day Day 4 Days Day Day 7 where R = reorder point mmean (average) demand during the lead time s-safety stock (or buffer stock) where 2- sadety factor o = standard deviation of demand during the lead time - leadtime x Then we have REM + ze Leadtime Meanwerapel demand per single period Mean (average cerrand during the lead time Serviceleve 141 Safety Factor, el lot demand during a single period lofcerranc during lead time) = 12 15 MUNT: wse ACIM SINV'service levels whols per day whsels (per lead time) = 14 Chapter 14 + + 100% ARO Week 4 - A-Learning Activity (1) Q Search Sheet Home Draw Page Layout Formulas Data Review View 9+ Share A Insert X Cut Wrap Text AutoSum A-A- * A Fill Copy r Format Paste B U- Merge & Center - Insert Delta Format Conditional Format Formatting as Table Call Styles Clear Sort & Filter Find & Select C14 . fix A T L M 0 P a R T U V W B D E F Your repair shop - Classic Cars--also sells replacement wheels in the lobby's retail shop. Compute the optimal order quantity for you to stock the '63-64 Corvette style rims in chrome-plated steel 15x6". Price charged to customers Cost pertem - 5 Inventory Holding Rate Usage last year Delivery costs Cast to place an order - $ S00.00 per wheel 359.50 per wheel 3ES 2,395 wheels 05.03 per shipment 30.00 per arder Q= 2SD iC D-demand rate, unita per year S-cost per order placed or setup cost, dollars per order C-nicot, dollars per unit 1 - carrying rate, percentage of dollar valve per year Olot size, bits TC-total of ordering cost plus carrying cost, dollars per year 11 12 EO- wheels per order HINT: round to the nearest whes to be closest to the minimum Total Cast. 13 14 15 16 Total Annual Inventory Com per year Note: Holding + Ordering costs HINT: Shipping is not an inventory Cost here. Tel SDU CO2 17 10 19 If the wheels must be ordered by the crate of 16 each, how many wheels (not crates would you order each time? EDO- whosis per order mual Cos you, IC How much would this policy make your new total annual inventory cost? New Total Annual Inventory Cast: per year Carrying out COV 22 23 Orderingen 24 Does this new crate only policy create a financial burden on your operational expenses EXO Dumilisi 25 26 27 Now, when should you re-order these wheel Compute the Ke-order Point, using the additional data below, a 90% service level and acondistent 7 day lead time. Date of Usage (wheels per day) days whelper day wheels per lead time MINT: m=dLeadtime where R- reorder point = mean (average) demand during the lead time s = safety stock (or buffer stock) where z = safety factor a = standard deviation of demand during the lead time = vleadtime x la Then we have 12 15 Leadtime- Meanwerpe demander urgle period Mean (averagel cerrand during the lead time Service Level 1 - Safety Factor, , tr| Glof demand during aside period lolcemand during lead time) 28 29 30 31 32 Day 2 33 Day 2 34 Day 1 35 Days 36 Day 6 37 Day 7 2 38 Daya 39 Days 40 Day 10 41 Day 11 42 Day 12 43 DEV13 HINT: we WONOM SIN Service levels wheels per day wheels (perlesdime) R 14 16 Rearder Peint-R- whals WINT moke sure to ROUND this number of wheels. If you want to hit your service target, consider munding Up So, when should you reorder these wheels? 4 12 R 7 12 Chapter 14 And finally when re-arder. how many should I buv + + 100%