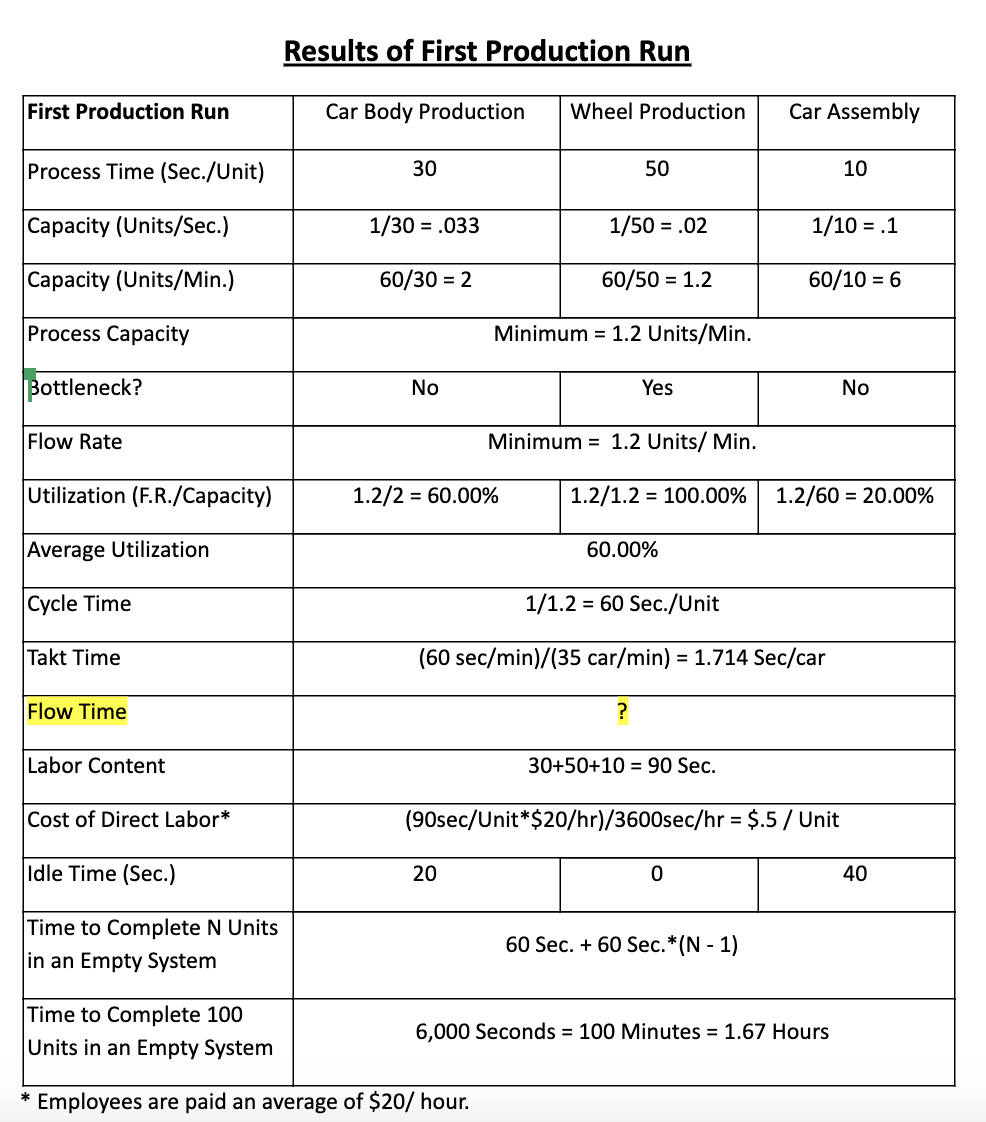

Question: Calculate the flow time based on information provided below? and show step by step Results of First Production Run First Production Run Car Body Production

Calculate the flow time based on information provided below? and show step by step

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock