Question: can you please answer this in depth and not assume or skip any steps please! themselves. Worn wires were to be replaced and an addi-

can you please answer this in depth and not assume or skip any steps please!

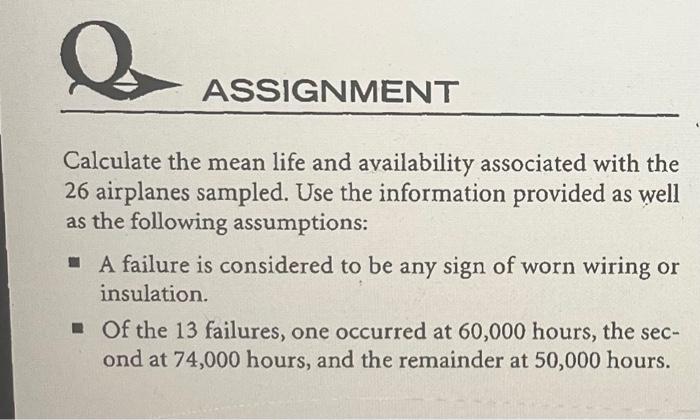

themselves. Worn wires were to be replaced and an addi- CASE STUDY 10.2 tional Teflon cover was to be put in place to add protection. On average, this inspection and repair took 15 hours to Reliability complete. Following indications that the explosion of TWA Flight 800 tion found a wiring bundle that showed clear signs of arcing was caused by electrical arcing, in May 1998, the Federal Avi- in one area and bare wires in another. These problems were ation Administration (FAA) ordered the inspection of hun-* found on a 737 with 60,000 hours of flying time. A similar dreds of Boeing 737s for potential wiring hazards. This fluation was found on another 737 with 74,000 hours of order grounded 15 percent ( 297 planes) of the 737s flown in out of two pin-sized holes in a tube that houses wires runthe United States. The planes in question were 737-100s and ning through one of the plane's wing fuel tanks. The combi737-200s with more than 50,000 hours, as well as later mod- nation of fuel, electricity, and air could ignite a fuel tank. els(737300,400,and500)withbetween40,000and50,000hours.Inspectionswereexpectedtocost$1,600perplane.ABoeing737hastwofueltanks,oneineachwing.TwofuelAfterthisfindingin737s,FAAandBoeingofficialscon-cludedthattwopin-sizedholesinapipecarryingelectrical pumps move fuel out of each tank. has shown that when wear through singection of aircraft wire arcing that caused the explosion of TWA Flight 800. arcs can carbonize the insulation, leading to oxists, small The inspection of the 737s continued. In the total samgreater potential for fire, Even though the wires are arcs and a ple of 26 planes, 13 of the 26 main pump lines inspected conduit (Figure (10.2.1 ), vibrations prevalent during flights show signs of wear on the wire insulation. These wiring cause the wires to chafe against each other and wear away the problems are related to the aging of the aircraft. Nearly all protective insulation. Foreign bodies such as sharp drill shav. the more than 3,000737s built are still flying. Many of them ings can wear away the insulation. Certain types of insulation are more than a quarter of a century old. The 737, a highly can be degraded by the fluids they come in contact with. respected workhorse of a plane, was expected to have a Affected planes were not to be returned to service until a life expectancy of 75,000 flights (takeoff-and-landing complete inspection had been made of their wiring and, cycles). Based on its current performance, this relatively when needed, repairs made. Mechanics searched for wear trouble-free aircraft may last as long as 195,000 cycles. on the insulation of the fuel pump wires and the wires Longevity has its complications though, as this wiring Calculate the mean life and availability associated with the 26 airplanes sampled. Use the information provided as well as the following assumptions: - A failure is considered to be any sign of worn wiring or insulation. - Of the 13 failures, one occurred at 60,000 hours, the second at 74,000 hours, and the remainder at 50,000 hours. The remaining planes showed no signs of failure when the test was terminated at 75,000 hours. - The average time to inspect and/or repair any of the planes was 15 hours

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock