Question: Capacity / Utilization You have a small factory. There are only 3 workers: an Assembler, Inspector, and Tester (for all products not for each). There

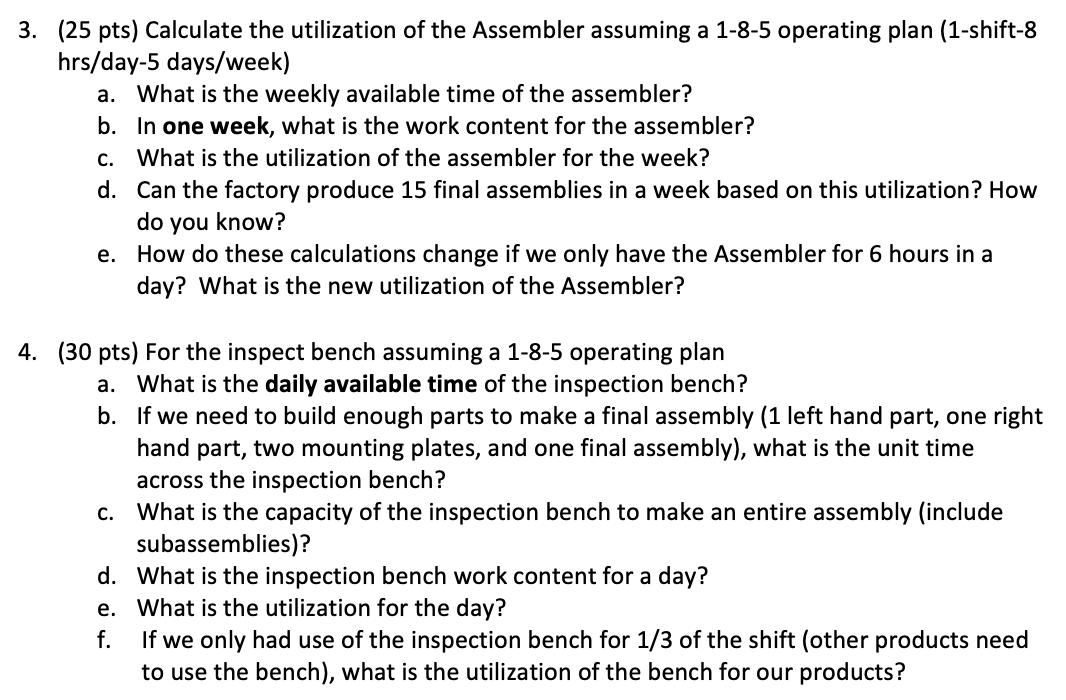

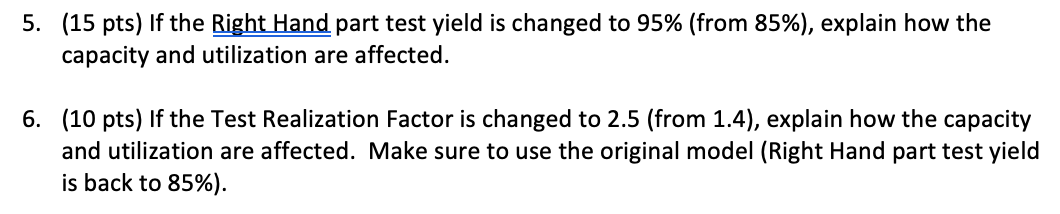

Capacity / Utilization You have a small factory. There are only 3 workers: an Assembler, Inspector, and Tester (for all products not for each). There are also only three benches (for all products not for each): an assembly bench, an inspector bench and a test position. The tester needs to be at the test station during the test and the test station is in use during tester time. Show work or explain answers for possibility of partial credit. 1. (10 pts) Calculate the rolled through yield for each of the parts listed below: a. Right hand part only (do not include the final assembly yields) b. Mounting plate only (do not include the final assembly yields) C. Left hand part including final assembly yields d. Mounting plate including final assembly yields 2. (10 pts) Calculate the quantity of parts needed to start at the operations listed below in order to get 15 final assemblies in a week: a. Right hand part test operation b. Left hand part inspect operation c. Mounting plate inspect operation d. Final assembly test operation 3. (25 pts) Calculate the utilization of the Assembler assuming a 1-8-5 operating plan (1-shift-8 hrs/day-5 days/week) a. What is the weekly available time of the assembler? b. In one week, what is the work content for the assembler? c. What is the utilization of the assembler for the week? d. Can the factory produce 15 final assemblies in a week based on this utilization? How do you know? e. How do these calculations change if we only have the Assembler for 6 hours in a day? What is the new utilization of the Assembler? 4. (30 pts) For the inspect bench assuming a 1-8-5 operating plan a. What is the daily available time of the inspection bench? b. If we need to build enough parts to make a final assembly (1 left hand part, one right hand part, two mounting plates, and one final assembly), what is the unit time across the inspection bench? C. What is the capacity of the inspection bench to make an entire assembly (include subassemblies)? d. What is the inspection bench work content for a day? e. What is the utilization for the day? f. If we only had use of the inspection bench for 1/3 of the shift (other products need to use the bench), what is the utilization of the bench for our products? 5. (15 pts) If the Right Hand part test yield is changed to 95% (from 85%), explain how the capacity and utilization are affected. 6. (10 pts) If the Test Realization Factor is changed to 2.5 (from 1.4), explain how the capacity and utilization are affected. Make sure to use the original model (Right Hand part test yield is back to 85%). Capacity / Utilization You have a small factory. There are only 3 workers: an Assembler, Inspector, and Tester (for all products not for each). There are also only three benches (for all products not for each): an assembly bench, an inspector bench and a test position. The tester needs to be at the test station during the test and the test station is in use during tester time. Show work or explain answers for possibility of partial credit. 1. (10 pts) Calculate the rolled through yield for each of the parts listed below: a. Right hand part only (do not include the final assembly yields) b. Mounting plate only (do not include the final assembly yields) C. Left hand part including final assembly yields d. Mounting plate including final assembly yields 2. (10 pts) Calculate the quantity of parts needed to start at the operations listed below in order to get 15 final assemblies in a week: a. Right hand part test operation b. Left hand part inspect operation c. Mounting plate inspect operation d. Final assembly test operation 3. (25 pts) Calculate the utilization of the Assembler assuming a 1-8-5 operating plan (1-shift-8 hrs/day-5 days/week) a. What is the weekly available time of the assembler? b. In one week, what is the work content for the assembler? c. What is the utilization of the assembler for the week? d. Can the factory produce 15 final assemblies in a week based on this utilization? How do you know? e. How do these calculations change if we only have the Assembler for 6 hours in a day? What is the new utilization of the Assembler? 4. (30 pts) For the inspect bench assuming a 1-8-5 operating plan a. What is the daily available time of the inspection bench? b. If we need to build enough parts to make a final assembly (1 left hand part, one right hand part, two mounting plates, and one final assembly), what is the unit time across the inspection bench? C. What is the capacity of the inspection bench to make an entire assembly (include subassemblies)? d. What is the inspection bench work content for a day? e. What is the utilization for the day? f. If we only had use of the inspection bench for 1/3 of the shift (other products need to use the bench), what is the utilization of the bench for our products? 5. (15 pts) If the Right Hand part test yield is changed to 95% (from 85%), explain how the capacity and utilization are affected. 6. (10 pts) If the Test Realization Factor is changed to 2.5 (from 1.4), explain how the capacity and utilization are affected. Make sure to use the original model (Right Hand part test yield is back to 85%)